30318 R4 9/9/2005

8

main electrical panel; however,

accessory equipment such as electronic

air cleaners and humidifiers may be

included on the furnace circuit. Although

a suitably located circuit breaker can be

used as a service switch, a separate

service switch is advisable. The service

switch is necessary if reaching the circuit

breaker involves becoming close to the

furnace, or if the furnace is located

between the circuit breaker and the

means of entry to the furnace room. The

furnace switch (service switch) should be

clearly marked, installed in an easily

accessible area between the furnace and

furnace room entry, and be located in

such a manner to reduce the likelihood

that it would be mistaken as a light

switch or similar device.

The power requirements for all models:

120 VAC, 1 ∅, 60 Hz., 12A.

Accessories requiring 120 VAC power

sources such as electronic air cleaners

and humidifier transformers may be

powered from the ST9103 EFT. Do not

use the direct drive motor connections as

a power source, since there is a high risk

of damaging the accessories by

exposure to high voltage from the auto-

generating windings of the direct drive

motor.

Thermostat wiring connections and air

conditioning contactor low voltage

connections are shown in the wiring

diagrams. Some micro-electronic

thermostats require additional controls

and wiring. Refer to the thermostat

manufacturer's instructions.

The thermostat should be located

approximately 5 feet above the floor, on

an inside wall where there is good

natural air circulation, and where the

thermostat will be exposed to average

room temperatures. Avoid locations

where the thermostat will be exposed to

cold drafts, heat from nearby lamps and

appliances, exposure to sunlight, heat

from inside wall stacks, etc.

Normal heat anticipator setting: 0.1 A.

For more precise adjustment, the heat

anticipator may be adjusted to the

amperage draw of the heating control

circuit as measured between the "R" and

"W" terminals of the thermostat. To

reduce the risk of damaging the heat

anticipator, do not measure circuit

without first removing one of the two

wires first. To determine the heating

circuit amperage draw:

1. Disconnect one of the “R” or “W”

wires from the thermostat terminal.

2. Connect an ammeter between the

wire and the thermostat terminal to

which it was attached.

3. Note the amperage reading when

the heating contacts are closed.

(System switch must be on “

HEAT” if

so equipped.

4. Re-connect the thermostat wire. If

the thermostat is serving a

combination heating and air

conditioning system, pay particular

attention to polarity.

5. When the thermostat is reconnected

and re-plumbed, adjust the heat

anticipator setting to match the

observed amperage reading.

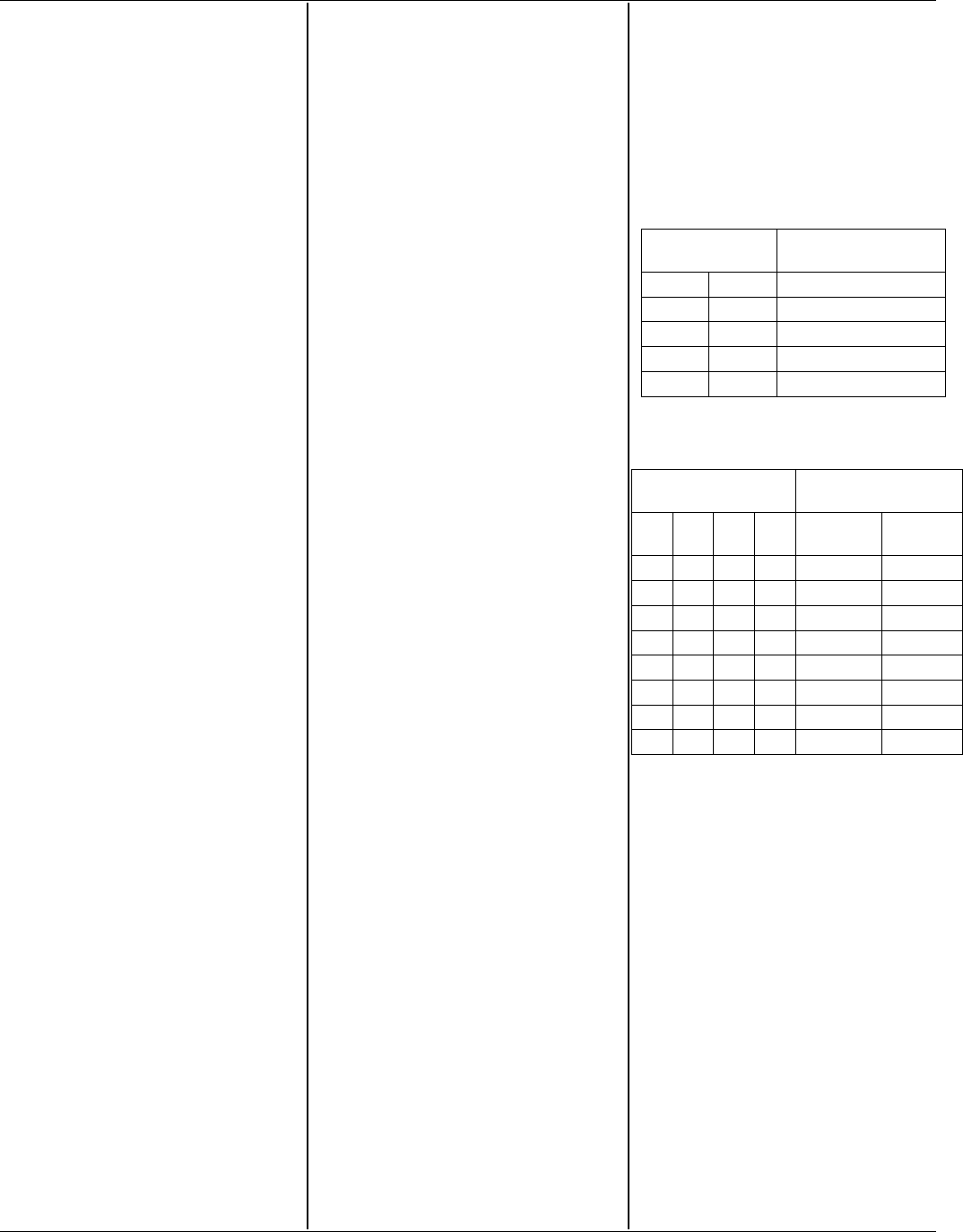

FAN TIMER BOARD AND LIMIT

CONTROL

The Electronic Fan Timer integrates

control of all burner and circulator fan

operations. This control is the central

wiring point for most of the electrical

components in the furnace. The

Honeywell ST9103 has a fixed fan delay

on time of 30 seconds after the burner

ignites. The United Technologies 1158-

120 has an adjustable fan on time that is

set by selecting the dipswitch

combination displayed in Table 6. This

fan on delay can be set at 30, 60, 90 or

120 seconds. This provides a delay

between the burner ignition and blower

start-up to eliminate excessive flow of

cold air when the blower comes on. The

Honeywell ST9103 has an adjustable

fan off time of 60, 90, 120 and 150

seconds that is set by selecting a

dipswitch combination on the control

board displayed in Table 5. Similarly the

United Technologies 1158-120 have an

adjustable fan off time of 2, 3, 4 or 6

minutes displayed in Table 6. The fan off

delay time starts when the burner motor

is de-energized at the end of a call for

heat. Blower shutdown is delayed to

remove any residual heat from the heat

exchanger and improve the annual

efficiency of the furnace.

The electronic fan timer board works in

conjunction with snap disc limit controls,

which perform a safety function, and

breaks power to the oil burner primary

control, which shuts off the burner if the

furnace over-heats. The limit control is

thermally operated and automatically

resets. The limit control is factory

installed, pre-set and is not adjustable.

If a limit control opens, the Honeywell

ST9103 will energize the circulating fan.

When the limit control closes the burner

is re-energized and the heating cycle

begins again.

If the limit control opens with the United

Technologies 1158-120 electronic fan

control, the circulating fan will be

energized as well. When the limit closes,

the control initiates a two minute delay.

When this delay is finished, the fan off

timer will begin. At the end of the fan off

time cycle the burner will be energized,

initiating a normal burner cycle.

TABLE 5

Honeywell ST9103

Dip Switch

Position

Blower Off Delay

Time

1 2

On On 60 seconds

On Off 90 seconds

Off On 120 seconds

Off Off 150 seconds

TABLE 6

United Technologies 1158-120

Dip Switch

Position

Blower Delay

Times

1 2 3 4 On

Seconds

Off

Minutes

Off Off 30

On Off 60

Off On 90

On On 120

Off Off 2

On Off 3

Off On 4

On On 6

Note: It is advisable not to set the

fan on delay time for a time period

longer than 90 seconds at highest

input. Longer fan on delay times

may result in nuisance limit trips.

CIRCULATING AIR BLOWER

All WML-C AND MPL-B furnace models

are equipped with a direct drive blower

system. Direct drive blower speed

adjustments are not normally required in

properly sized extended plenum duct

systems. The motor RPM and air CFM

delivery will vary automatically to

accommodate conditions within the usual

range of external static pressures typical

of residential duct systems. Under-sized

duct systems may require a higher

blower speed to obtain a reasonable

system temperature rise. Some older

duct systems were not designed to

provide static pressure. They typically

feature special reducing fittings at each

branch run and lack block ends on the