Instruction Manual

760004-A

February 2002

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-1

Model NGA 2000 HFID

SECTION 1

DESCRIPTION AND SPECIFICATIONS

1-1 OVERVIEW

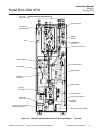

This manual describes the Heated Flame Ioni-

zation Detector (HFID) Analyzer Module of

Rosemount Analytical's NGA 2000 Series of

gas analysis components. See Figure 1-1 and

Figure 1-2.

The HFID Analyzer Module is designed to con-

tinuously determine the concentration of hydro-

carbons in a flowing gaseous mixture at a

user-selectable temperature setpoint between

93°C and 204°C (200°F and 400°F). The con-

centration is expressed in ppm or percent of

volume.

The entire HFID Analyzer Module is designed

as a stand-alone module, with gas connections

made from the rear. All electronics relative to

sample detection and conditioning are included

in this module.

1-2 TYPICAL APPLICATIONS

The monitoring of atmospheric air for low-level

hydrocarbon contaminants and determining the

hydrocarbon content of exhaust emissions from

internal combustion engines are examples of

typical applications for the HFID Analyzer Mod-

ule.

1-3 SAFETY GAS FEATURES

The HFID Analyzer Module is designed with a

factory-installed continuous dilution purge sys-

tem in accordance with standard ANSI/NFPA

496 - 1993, Chapter 6. Front-panel LEDs indi-

cate that the burner flame is lit and that the

purge system is enabled. In addition, fuel gas is

automatically shut off when a flame-out condi-

tion occurs or the safety system is disabled.

The purge system is enabled only if there is

proper purge gas flow in, purge gas pressure,

and internal case pressure, and after five times

the case volume has been exchanged.

All tubing ahead of the burner is rigid metal-

lic tubing assembled with ferrule/nut type

compression fittings. However, should an

internal fuel leak occur, a worst-case leak

would be dissipated below 25% of the LEL

of hydrogen through the combination of an

inlet fuel flow restrictor and purge gas flow.

This module is designed to use 40%

H

2

/60% He fuel at a maximum inlet pres-

sure of 3446 hPa-gauge (50 psig).

A standard HFID Analyzer Module is only

equipped to analyze a non-flammable sam-

ple, below 100% of the LEL.

WARNING

POSSIBLE EXPLOSION HAZARD

Protection against explosion depends

upon a special fuel flow restrictor in the

fuel inlet fitting. Do not remove fuel inlet

restrictor. Do not use 100% hydrogen

fuel. Replace only with a factory sup-

plied fitting.

1-4 THEORY OF TECHNOLOGY

This Analyzer Module uses the flame ioni-

zation method of detection. The sensor is a

burner in which a regulated flow of sample

gas passes through a flame sustained by

regulated flows of a fuel gas (a hydro-

gen/diluent mixture) and air.

Within the flame, the hydrocarbon compo-

nents of the sample stream undergo a com-

plex ionization that produces electrons and

positive ions. Polarized electrodes collect

these ions, causing current to flow through

an electronic measuring circuit.

The ionization current is proportional to the

rate at which carbon atoms enter the

burner, and is therefore a measure of the