M48 Tank

12

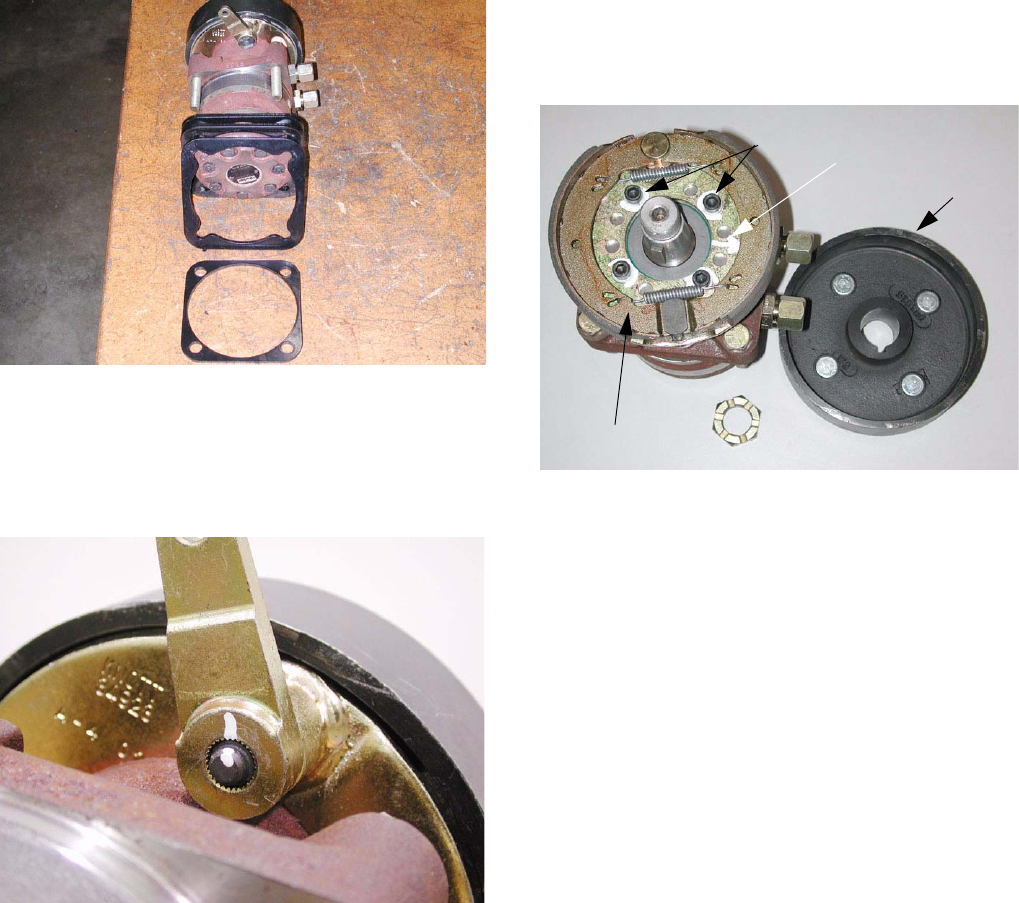

6.16. Withdraw the hydro motor, along with the three

motor spacers, and place them gently on a work

bench. See Figure 6.16.

6.17. If the brake is to be removed, remove the clip

that holds the brake arm on the splined shaft,

and mark the location of the brake arm on the

splined shaft.

6.18. Remove the brake arm from the splined shaft.

NOTE: The Hydro motor can be ordered with or

without the brake assembly. If an appropriate

size press is not available, the dealer should

consider ordering hydro motor with the brake

assembly attached.

6.19. Safely fixture the hydro motor and brake assem-

bly in a minimum 20 Ton press so that the ram

presses against the end of the axle, and the

assembly is supported by the edge of the brake

drum. Press the drum off of the tapered shaft.

6.20. Remove the castle nut and brake drum from the

axle. See Figure 6.20.

6.21. Mark the orientation of the brake assembly on

the hydro motor.

6.22. Remove the four socket head cap screws that

hold the brake assembly to the hydro motor

using a 1/4” allen wrench.

6.23. Transfer the four mounting bolts from the old

hydro motor to the new one. Replace any that

show signs of wear or damage.

6.24. Position the three motor spacers on the bolts,

and install the hydro motor in the TANK.

6.25. Place the motor plate over the end of the bolts,

apply Loctite 242 (blue) the the bolts, and install

the four nuts. Tighten the bolts to 450-550 in.-

lbs.

6.26. Inspect the brake assembly. If there are not

signs of significant wear or damage, install the

brake on the new hydro motor, using the match

marks to maintain the same orientation.

6.27. Use new lock washers and / or Loctite 242 (blue)

when installing the brake assembly. Torque the

socket head cap screws to 160-200 in.-lbs.

Figure 6.16

Figure 6.17

Figure 6.20

BRAKE

ASSEMBLY

ORIENTATION MARKS

(ARROW TO FITTINGS)

DRUM

BRAKE