37

The input rating for altitudes above 2,000 ft. (610 M) must

be reduced by 4 percent for each 1,000 ft. (305 M) above

sea level. For installations below 2000 ft. (610 M), refer to

the unit rating plate. For installations above 2000 ft. (610

M), multiply the input on the rating plate by the de--rate

multiplier in Table 8 for the correct i nput rate.

In Canada:

The input rating must be derated by 10 percent for

altitudes of 2,000 ft. (610 M) to 4,500 ft. (1372 M) above

sea level by an authorized Gas Conversion Station or

Dealer. To determine correct input rate for altitude, see

example 1 and use 0.90 as derate multiplier factor.

EXAMPLE 1:

88,000 BTUH INPUT FURNACE INSTALLED AT 4300

FT. (1310 M)

Furnace Input

Rate at Sea

Level

X Derate

Multiplier

Factor

0.90

= Furnace Input

Rate at

Installation

Altitude

88,000 X = 79,200

2. Determine the correct orifice and manifold pressure

adjustment. There are two different orifice and manifold

adjustment tables. All models in all positions, except Low

NOx models in downflow or horizontal positions, use

Table 13 (22,000 Btuh/Burner).

Low NOx models in the downflow or horizontal positions

must use Table 14 (21,000 Btuh/Burner). See input listed

on rating plate.

a. Obtain averageyearly gasheat value(atinstalledaltitude)

from local gas supplier.

b. Obtain average yearly gas specific gravity from local gas

supplier.

c. Find installation altitude in Table 13 or 14.

d. Find closest natural gas heat value and specific gravity

in Table 13 or 14.

e. Follow heat value and specific gravity lines to point of

intersection to find orifice size and manifold pressure

settings for proper operation.

f. Check and verify burner orifice size in furnace. NEVER

ASSUME ORIFICE SIZE. ALWAYS CHECK AND

VERIFY.

g. Replace orifice with correct size if required by Table 10,

12, 13, and 14. Use only factory --supplied orifices. See

EXAMPLE 2 .

Caution!! For the following applications, use the minimum vertical vent heights as specified below. For all other applications,

follow exclusively the National Fuel Gas Code.

FURNACE

ORIENTATION

VENT ORIENTATION

FURNACE INPUT

(BTUH/HR)

MIN. VENT

DIAMETER

IN (MM)*

MIN. VERTICAL VENT

HEIGHT

FT.(M)**

Downflow Vent elbow left, then up Fig. 38 132,000 5 (127 ) 12 (4)

Horizontal Left Vent elbow right, then up Fig. 41 132,000 5 (127 ) 7(2)

Horizontal Left Vent elbow right Fig. 42 132,000 5 (127 ) 7(2)

NOTE: All vent configurationsmust also meet National Fuel Gas Code ventingrequirementsNFGC

*4 in. (102 mm) inside casing or vent guard

**Including 4 in. (102 mm) vent section(s)

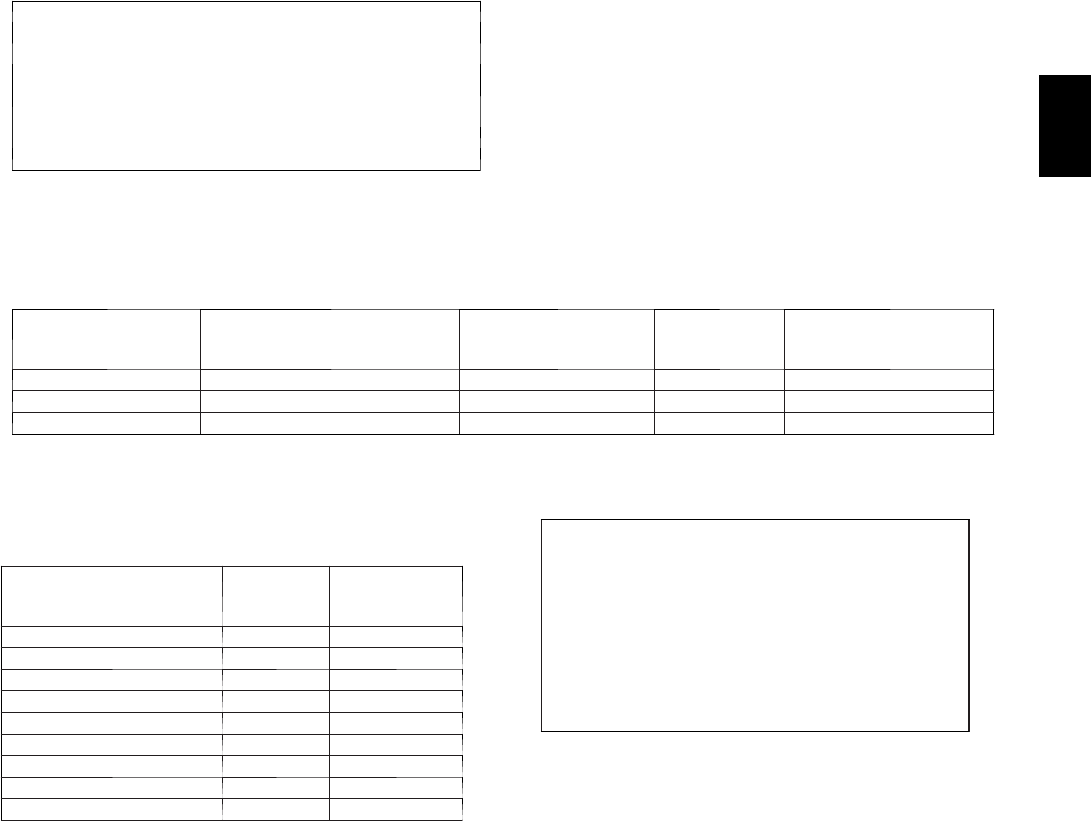

Table 10 – Altitude Derate Multiplier for U.S.A.

ALTITUDE

(FT. / M)

PERCENT

OF

DERATE

DERATE

MULTIPLIER

FACTOR*

0–2000 (0---610) 0 1.00

2001–3000 (610---914) 8–12 0.90

3001–4000 (914---1219) 12–16 0.86

4001–5000 (1219---1524) 16–20 0.82

5001–6000 (1524---1829) 20–24 0.78

6001–7000 (1829---2134) 24–28 0.74

7001–8000 (2134---2438) 28–32 0.70

8001–9000 (2438---2743) 32–36 0.66

9001–10,000 (2743---3048) 36–40 0.62

* Derate mul tiplier f actors are based on midpoint altitu de for altitude

range.

3. Adjust manifold pressure to obtain correct input rate.

a. Turn gas valve ON/OFF switch to OFF.

b. Removemanifoldpressuretapplug fromgasvalve. (See

Fig. 52.)

c. Connect a water column manometer or similar device to

manifold pressure tap.

d. Turn gas valve ON/OFF switch to ON.

e. Manually close blower door switch.

f. Set thermostat to call for heat.

g. Remove regulator seal cap and turn regulator adjusting

screw counterclockwise (out) to decrease input rate of

clockwise (in) to increase input rate.

EXAMPLE 2: (0 to 2000 ft. (0 to 610 M) altitude)

For 22,000 Btuh per burner application use Table 13.

Heating value = 1000 Btuh/cu ft.

Specific gravity = 0.62

Therefore: Orifice No. 43*

Manifold pressure: 3.7--in. wc

*Furnace is shipped with No. 43 orifices.

In this example all main burner orifices are the correct

size and do not need to be changed to obtain proper

input rate.

h. Install regulator seal cap.

i. Leave manometer or similar device connected and

proceed to Step 4.

NOTE: DO NOT set manifold pressure less than 3.2--in wc or

more than 3.8--in. wc for natural gas at sea level. If manifold

pressure is outside this range, change main burner orifices. Refer

to Table 10, 12, 13, and 14.

NOTE: If orifice hole appears damaged or it is suspected to have

been redrilled, check orifice hole with a numbered drill bit of

correct size. Never redrill an orifice. A burr--free and squarely

aligned orifice hole is essential for proper flame characteristics.

4. Verify natural gas input rate by clocking meter.

NOTE: Gas valve regulator adjustment cap must be in place for

proper input to be clocked.

a. Turn of f all other gas appliances and pilots served by the

meter.

b. Run furnace for 3 minutes in heating operation.

58PHA