Step 7—Install Electrical Connections

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

The unit cabinet must have an uninterrupted, unbroken

electrical ground to minimize the possibility of personal

injury if an electrical fault should occur. This ground may

consist of an electrical wire connected to the unit ground in

the control compartment, or conduit approved for electrical

ground when installed in accordance with NEC (National

Electrical Code), ANSI (American National Standards

Institute)/NFPA (latest edition) (in Canada, Canadian Elec-

trical Code CSA C22.1) and local electrical codes.

UNIT DAMAGE HAZARD

Failure to follow these precautions may result in damage to

the unit being installed:

1. Make all electrical connections in accordance with NEC

ANSI/NFPA (latest edition) and local electrical codes

governing such wiring. In Canada, all electrical connec-

tions must be in accordance with CSA standard C22.1

Canadian Electrical Code Part 1 and applicable local

codes. Refer to unit wiring diagram.

2. Use only copper conductor for connections between

field-supplied electrical disconnect switch and unit. DO

NOT USE ALUMINUM WIRE.

3. Be sure that high-voltage power to unit is within operating

voltage range indicated on unit rating plate.

4. Insulate low-voltage wires for highest voltage contained

within conduit when low-voltage control wires are run in

same conduit as high-voltage wires.

5. Do not damage internal components when drilling through

any panel to mount electrical hardware, conduit, etc.

Consult local power company for correction of improper

voltage.

HIGH-VOLTAGE CONNECTIONS

The unit must have a separate electrical service with a field-

supplied, waterproof disconnect switch mounted at, or within sight

from the unit. Refer to the unit rating plate for maximum

fuse/circuit breaker size and minimum circuit amps (ampacity) for

wire sizing. See Table 6 for electrical data.

The field-supplied disconnect may be mounted on the unit over the

high-voltage inlet hole. (See Fig. 2.)

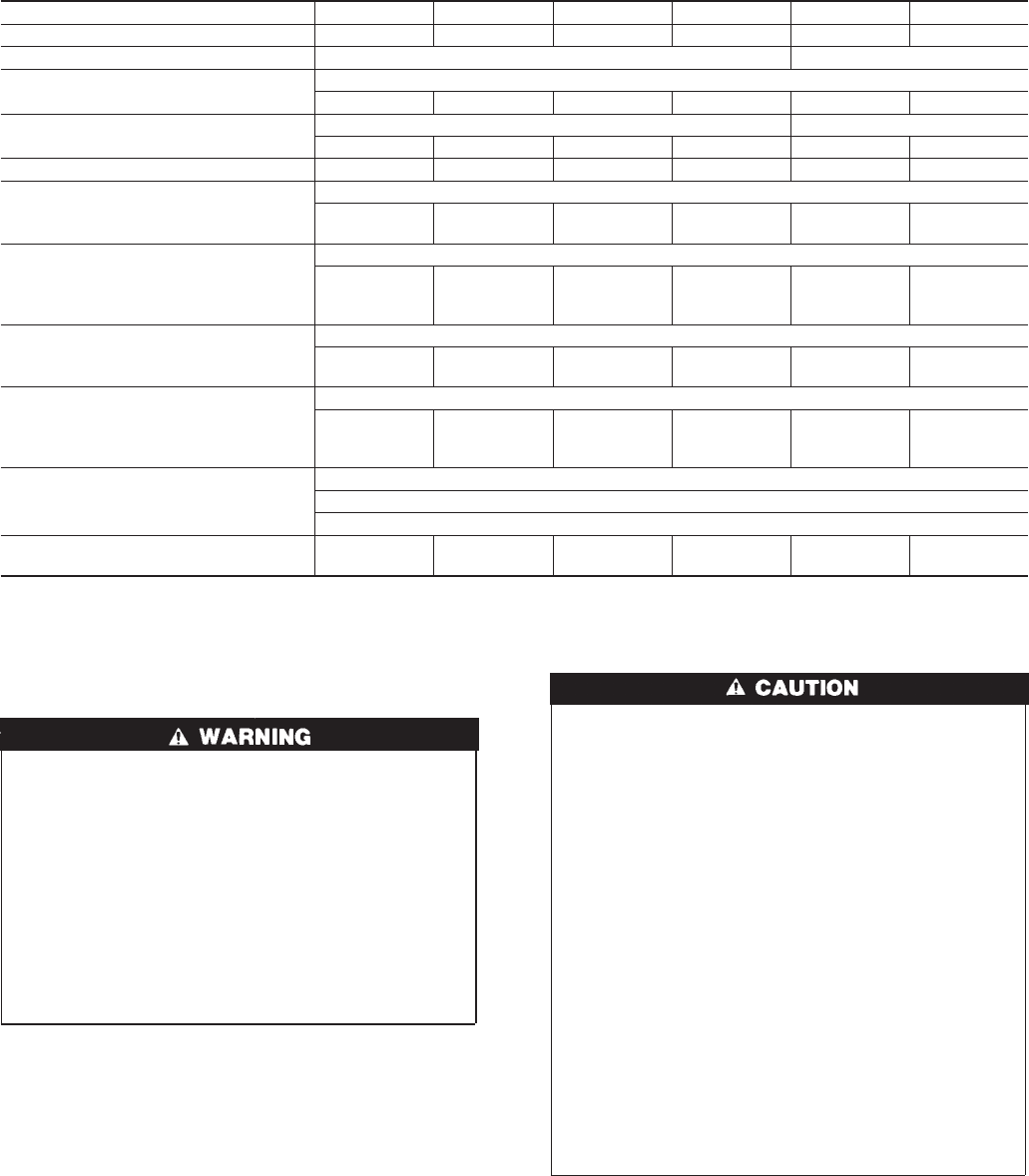

Table 2—Physical Data

UNIT 50ZHA 024 030 036 042 048 060

OPERATING WEIGHT (lbs) 293 324 377 389 384 433

COMPRESSOR TYPE Scroll Ultra Tech Scroll

REFRIGERANT Charge (lb)

R-22

7.5 10.3 10.3 11.9 11.4 13.3

REFRIGERANT METERING DEVICE

Orifice ID (in.)

Accurater TXV

.067 .067 .082 .086 — —

Orifice OD (in.) .049 .057 .059 .063 .070 .073

CONDENSER COIL

Rows...Fins/in.

Face Area (sq. ft.)

Copper Tubes, Aluminum Plate Fins

2...21

11.1

2...21

12.7

2...21

15.8

2...21

15.8

2...21

13.3

2...21

15.8

CONDENSER FAN

Nominal Cfm

Diameter (in.)

Motor HP (RPM)

Propeller

2600

20

1/8 (825)

2600

20

1/8 (825)

3200

20

1/4 (1100)

3200

20

1/4 (1100)

3200

20

1/4 (1100)

3300

20

1/2 (1100)

EVAPORATOR COIL

Face Area (sq. ft.)

Copper Tubes, Aluminum Plate Fins

3...17

4.3

3...17

4.9

4...17

4.9

4...17

6.1

4...17

4.9

4...17

6.1

Evaporator Blower

Nominal Airflow (CFM)

Size (in.)

Motor HP (RPM)

Direct Drive

800

10x8

1/2 (1050)

1000

10x8

1/2 (1050)

1200

11x9

3/4 (1050)

1400

11x9

3/4 (1050)

1600

11x10

1 (1050)

1875

11x10

1 (1050)

CONNECTING DUCT SIZES

Supply Air (in.)

Return Air (in.)

Round

14

14

Return-Air Filters (in.)*

Throwaway

24x24 24x24 24x24 24x30 30x30 30x30

*Required filter sizes shown are based on the ARI (Air Conditioning and Refrigeration Institute) rated airflow at a velocity of 300 ft/min for throwaway type or 450 ft/min

for high capacity type. Recommended filters are 1-in. thick.

5