COOLING OPERATION (SIZES 024-042)

With a call for cooling (Y/Y2), the indoor fan energizes immedi-

ately whereas the contactor energizes aftera5minute time delay

(in case of initial start-up) starting the compressor and the outdoor

fan motor. When the cooling demand is met, Y/Y2 de-energizes,

shutting the compressor, indoor fan and the outdoor fan.

COOLING OPERATION (SIZES 048 AND 060)

These units utilize a 2 stage indoor thermostat. With a first stage

call for cooling (Y1), the indoor fan (low stage) energizes

immediately whereas the contactor energizes aftera5minute time

delay (in case of an initial start-up) starting the compressor (low

stage) and the outdoor fan motor. If the low stage operation cannot

satisfy the cooling demand, the second stage cooling (Y2) ener-

gizes switching the compressor into high stage cooling through

energizing an internal solenoid valve inside the scroll compressor

and switching the indoor fan into high stage. When second stage

cooling is satisfied, Y2 de-energizes switching the compressor and

the indoor fan into low stage cooling. When the low stage cooling

demand is met, Y1 de-energizes shutting the compressor, indoor

fan and the outdoor fan.

HEATING OPERATION (SIZES 024-042)

With a call for heating (Y1), the indoor fan (low stage) energizes

immediately whereas the contactor energizes aftera5minute time

delay (in case of initial start-up) starting the compressor and the

outdoor fan motor. If Y/Y2 cannot satisfy the heating demand, the

auxiliary or backup heat (W2) energizes. In case of staged heating,

W3 is energized if the demand is not met. The highest airflow

selected is run while the electric heat is in operation. When heating

demand is met, W3, W2 and Y/Y2 sequentially de-energize

shutting the compressor, indoor fan and the outdoor fan.

HEATING OPERATION (SIZES 048 AND 060)

With a first stage call for heating (Y1), the indoor fan (low stage)

energizes immediately whereas the contactor energizes after a 5

minute time delay (in case of initial start-up) starting the compres-

sor (low stage) and the outdoor fan motor. If the low stage

oepration cannot satisfy the heating demand, the second stage

heating (Y2) energizes switching the compressor into high stage

heating through energizing an internal solenoid valve inside the

scroll compressor and switching the indoor fan into high stage. The

auxiliary or backup heat is controlled by a third stage (W2). If the

demand is not met, W3 is energized in case of staged heating.

When heating demand is satisfied, W3, W2 and Y2 sequentially

de-energize switching the compressor and the indoor fan into low

stage heating. When the low stage heating demand is met, Y1

de-energizes shutting the compressor, indoor fan and the outdoor

fan.

CONTINUOUS FAN

With the continuous Indoor fan option selected on the thermostat,

G is continuously energized. In case of 024-042 units, the selected

airflow setting is provided. In case of 048 and 060 units, the

system runs low stage (Y1) airflow for continuous fan operation.

DEFROST

Defrost board (DB) is a time and temperature control, which

includes a field-selectable time period between checks for defrost

(30, 60, 90 and 120 minutes). The time period is factory-set at 60

minutes and should only be adjusted by a trained service person.

Electronic timer and defrost cycle start only when contactor is

energized and defrost thermostat (DFT) is closed.

Defrost mode is identical to Cooling mode. The outdoor fan motor

stops because of “OF1” and “OF2” contacts opening on the defrost

board, a bank of optional electric heat turns on to warm air

supplying the conditioned space.

ELECTRIC RESISTANCE HEATING

If accessory electric heaters are installed, on a call for “Emergency

Heat” the thermostat energizes W which energizes the heater relay

and in turn energizes the electric heaters. The IFR is energized

which starts the indoor-fan motor. If the heaters are staged, W2 is

energized when the second stage of heating is required. When the

need for heating is satisfied, the heater and IFM are de-energized.

MAINTENANCE

To ensure continuing high performance, and to reduce the possi-

bility of premature equipment failure, periodic maintenance must

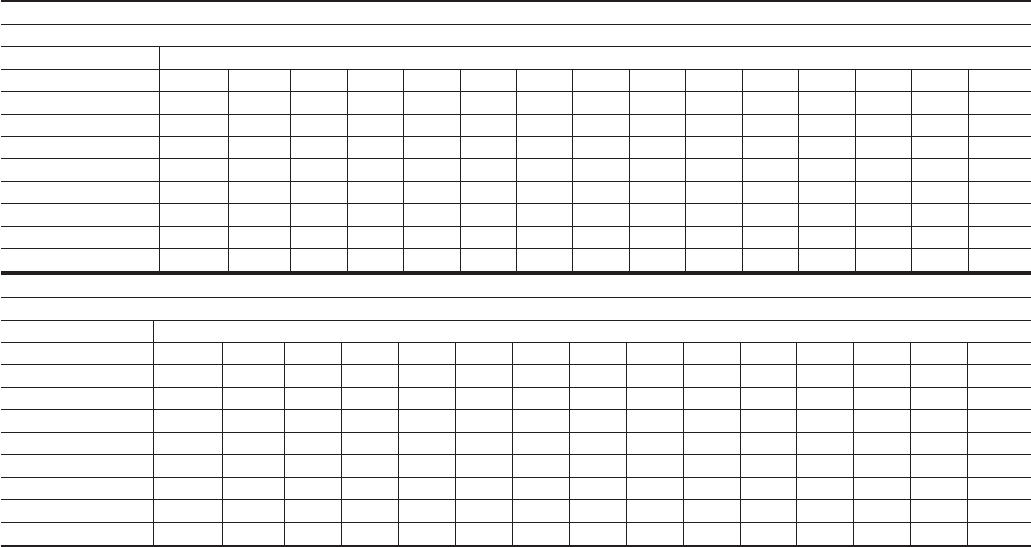

Table 8—Cooling Charging Chart

SUCTION LINE TEMPERATURE (°F)

Suction Line Pressure (PSIG)

OD Temp. (°F) 52 54 56 59 61 64 67 70 73 76 79 82 85 89 92

45 51 55606469——————————

55 — —5357626670————————

65 — ———535762667175—————

75 — ——————5661667176———

85 — ———————5358636772——

95 — ————————5054586266—

105 — —————————5053576064

115 — —————————4952555861

125 — ——————————50535659

SUCTION LINE TEMPERATURE (°C)

Suction Line Pressure (kPa)

OD Temp. (°C) 361 370 387 405 423 442 462 482 502 523 544 566 589 612 636

7 11 13151821——————————

13 — —1214161921————————

18 — ———121417192124—————

24 — ——————1316192224———

29 — ———————1214172022——

35 — ————————1012141719—

41 — —————————1012141618

46 — ————————— 911131416

52 — ——————————10111315

14