NOTE: Be sure that all supply- and return-air grilles are open,

free from obstructions, and adjusted properly.

Disconnect electrical power to the unit and install lockout tag

before changing blower speed. Electrical shock can cause

serious injury or death.

Airflow can be changed by changing the lead connections of the

blower motor.

Units 50ZH024, 036, 048, and 060 blower motors are factory

wired for low speed operation. Units 50ZH030 and 042 are factory

wired for medium speed operation.

FOR 208/230-V

The motor leads are color-coded as follows:

To change the speed of the indoor fan motor (IFM), remove the fan

motor speed leg lead from the indoor fan relay (IFR) with units

024, 030, 042, 048 & 060 or the time delay relay (TDR) on 036

size and replace with lead for desired blower motor speed. Insulate

the removed lead to avoid contact with chassis parts.

FOR 460-V MOTORS

The motor leads are color coded as follows:

To change the speed of the indoor fan motor (IFM) from low speed

to high speed, remove the red lead from the indoor-fan relay (IFR).

ON 2–Speed Motors: Insulate the red lead to avoid contact with

any chassis parts. Separate the black lead from the purple lead.

Connect the black lead to the IFR. Insulate the purple lead to avoid

contact with any chassis parts. ON 3–Speed Motors: remove the

fan motor speed leg lead from the indoor (indoor) fan relay (IFR)

and replace with lead for desired blower motor speed.

Step 5—Unit Controls

All compressors have the following internal-protection controls.

HIGH-PRESSURE RELIEF VALVE

This valve opens when the pressure differential between the low

and high side becomes excessive (024 size has temperature relief

only).

LOSS OF CHARGE SWITCH

Located on the outdoor liquid line is a low-pressure switch which

functions as a loss-of-charge switch. This switch contains a

Schrader core depressor. This switch opens at 7 psig and closes at

22 psig. No adjustment is necessary.

COMPRESSOR OVERLOAD

This overload interrupts power to the compressor when either the

current or internal temperature become excessive, and automati-

cally resets when the internal temperature drops to a safe level.

This overload may require up to 60 minutes (or longer) to reset;

therefore, if the internal overload is suspected of being open,

disconnect the electrical power to the unit and check the circuit

through the overload with an ohmmeter or continuity tester.

Step 6—Sequence of Operation

FAN OPERATION

The FAN switch on the thermostat controls indoor fan operation.

When the FAN switch is placed in the ON position, the IFR

(indoor-fan relay) is energized through the G terminal on the

thermostat. The normally-open contacts close, which then provide

power to the indoor (evaporator) fan motor (IFM). The IFM will

run continuously when the FAN switch is set to ON.

When the FAN switch is set to AUTO, the thermostat deenergizes

the IFR (provided there is not a call for cooling). The contacts open

and the IFM is deenergized. The IFM will be energized only when

there is a call for cooling, in heat pump heating mode or if the unit

is equipped with accessory electric heat, the indoor-fan motor will

also run while the accessory electric heat is energized.

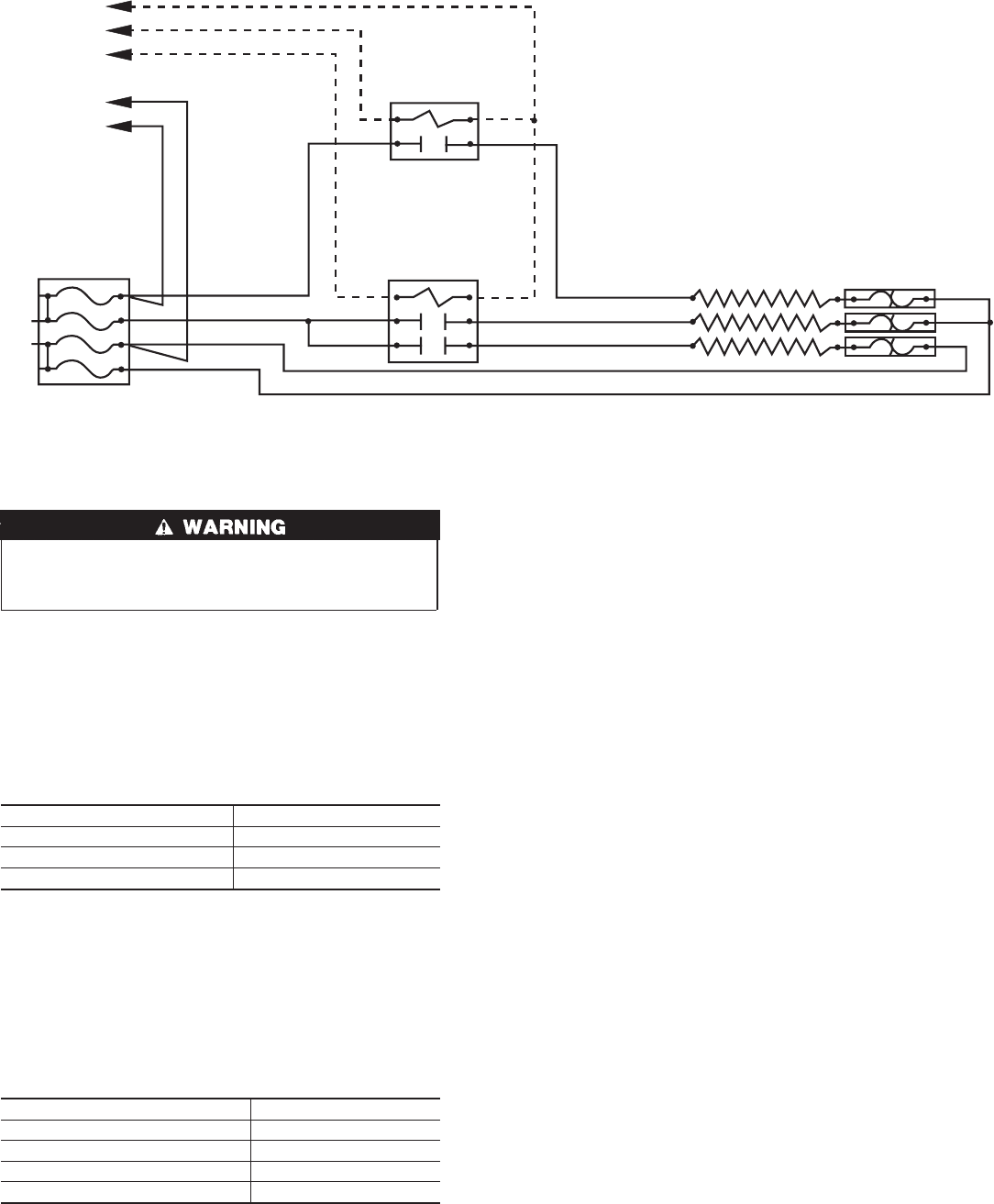

Fig. 15B—Accessory Electric Heater Wiring

C00014

C

W1

W1

TO

UNIT POWER

WIRING

BLK

YEL

BRN (COMMON)

VIO (STEP 2)

WHT ( STEP 1)

CONTACTOR 2

YEL

BRN

YEL

CONTACTOR 1

YEL

YEL

BRN

YEL

YEL

FUSE BLOCK

L2

L1

YEL

YEL

BLK

BLK

F3

F4

F1

F2

EL 1

EL 2

EL 3

BLK

BLK

BLK

AUTO-LIMIT

3-SPEED 2-SPEED

black = high speed black = high speed

blue = medium speed -

red = low speed red = low speed

3-SPEED (060 ONLY) 2-SPEED

black = high speed black = to purple

- yellow = line

orange = medium speed purple = to black

blue = low speed red = line

12