8

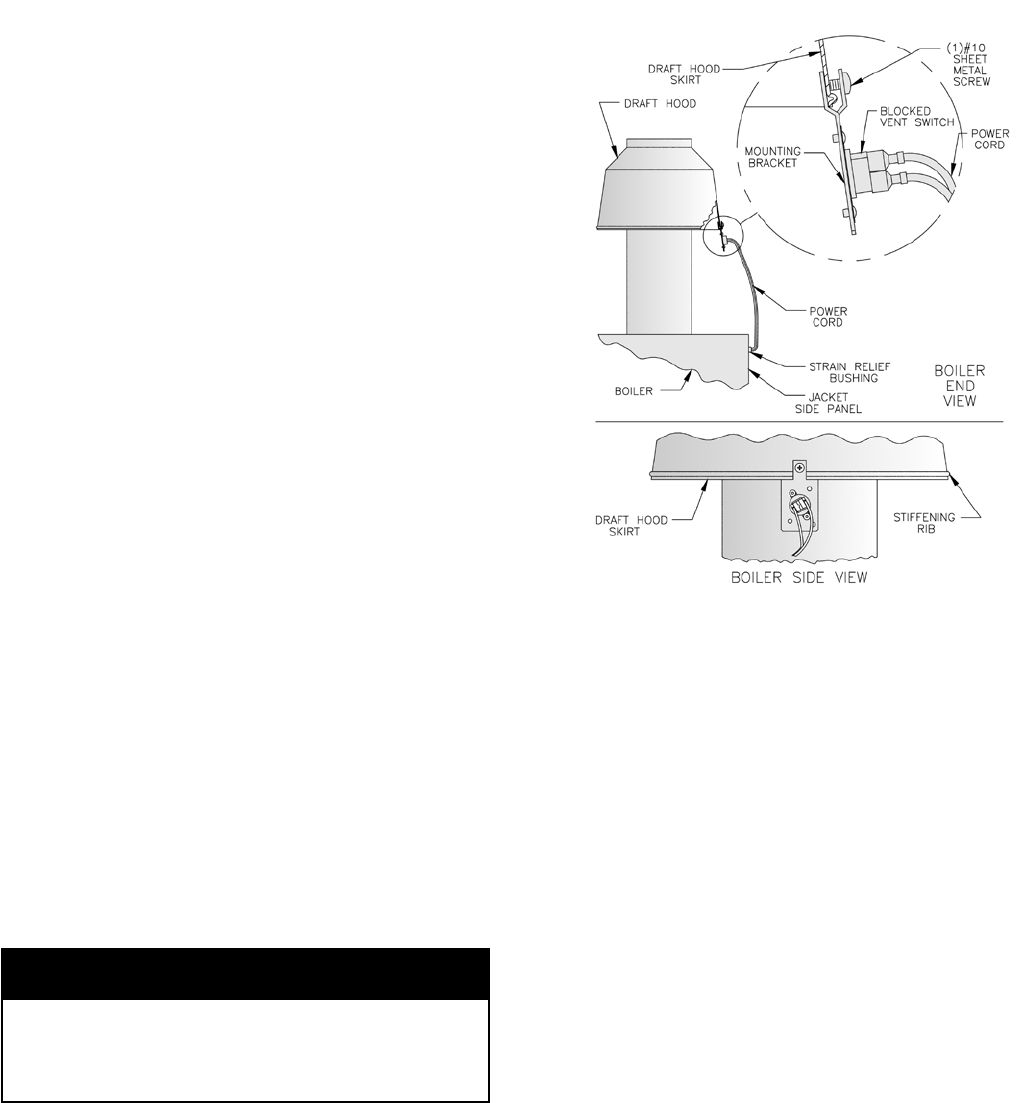

Figure 6

B. Pinch the black strain relief bushing installed in the

jacket right side panel to dislodge it from the jacket

and pull just enough of the black power cord out so

the blocked vent switch will reach the near side of

the draft hood skirt. Do not pull out more power

cord than necessary.

C. Position the mounting bracket (with switch attached)

onto the lower edge of the draft hood skirt by

locating the center tooth (with the #10 sheet metal

screw) on the outside and the other two teeth inside

the draft hood skirt. See Figure 6.

D. Slide the mounting bracket up tight against the

lower edge of the draft hood skirt, so that the #10

sheet metal screw is above the skirt's stiffening rib.

E. Secure the bracket in this position by tightening the

#10 sheet metal screw against the outer surface of

the draft hood skirt.

F. Reinsert the excess power cord through the jacket

side panel hole to take the slack out of the power

cord running up to the blocked vent switch.

G. Reposition the strain relief bushing around the

power cord at the jacket side panel, pinch the two

halves of the bushing together, and snap it back into

the hole in the jacket side panel to secure the power

cord to the jacket.

H. Be sure the power cord, mounting bracket, and

switch are secure and located as shown in Figure 6.

To perform a long term pressure test including the

boiler, ALL trapped air must rst be removed from

the boiler.

A loss of pressure during such a test, with no visible

water leakage, is an indication that the boiler

contained trapped air.

K. OXYGEN CORROSION:

Oxygen contamination of the boiler water will cause

corrosion of the iron and steel boiler components,

which can lead to failure. As such, any system must

be designed to prevent oxygen absorption in the rst

place or prevent it from reaching the boiler.

Problems caused by oxygen contamination of boiler

water are not covered by Burnham's standard

warranty.

There are many possible causes of oxygen

contamination such as:

1. Addition of excessive make-up water as a result

of system leaks.

2. Absorption through open tanks and ttings.

3. Oxygen permeable materials in the distribution

system.

In order to insure long product life, oxygen

sources should be eliminated. This can be

accomplished by taking the following measures:

1. Repairing system leaks to eliminate the need for

addition of make-up water.

2. Eliminating open tanks from the system.

3. Eliminating and/or repairing ttings which allow

oxygen absorption.

4. Use of non-permeable materials in the

distribution system.

5. Isolating the boiler from the system water by

installing a heat exchanger.

10. INSTALL DRAFT HOOD without modication on

outlet of ue collector (See Figure 1). Secure with sheet

metal screws.

WARNING

Do not alter boiler draft hood or place any

obstruction or non-approved damper in the

breeching or vent system. Flue gas spillage can

occur. ETL certication will become void.

11. INSTALL BLOCKED VENT SWITCH

The blocked vent switch assembly shipped taped to the

top of the boiler includes a power cord and a switch

attached to a mounting bracket. The mounting bracket

has a three tooth staggered comb stamping at one end

with a #10 sheet metal screw in the center tooth.

A. Untape the blocked vent switch assembly from the

top of the boiler and uncoil the power cord.