26

IV. Service

1. Inspection should be conducted annually. Service as

frequently as specied in paragraphs below. While

service or maintenance is being done, Electrical Power

and all Gas Supply to the Boiler must be "off".

CAUTION

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation. Verify

proper operation after servicing.

ATTENTION. Au moment de l’entretien des

commandes, étiquetez tous les ls avant

de les débrancher. Les erreurs de câblage

peuvent nuire au bon fonctionnement et être

dangereuses.

S’assurer que l’appareil fonctionne

adéquatement une fois l’entretien terminé.

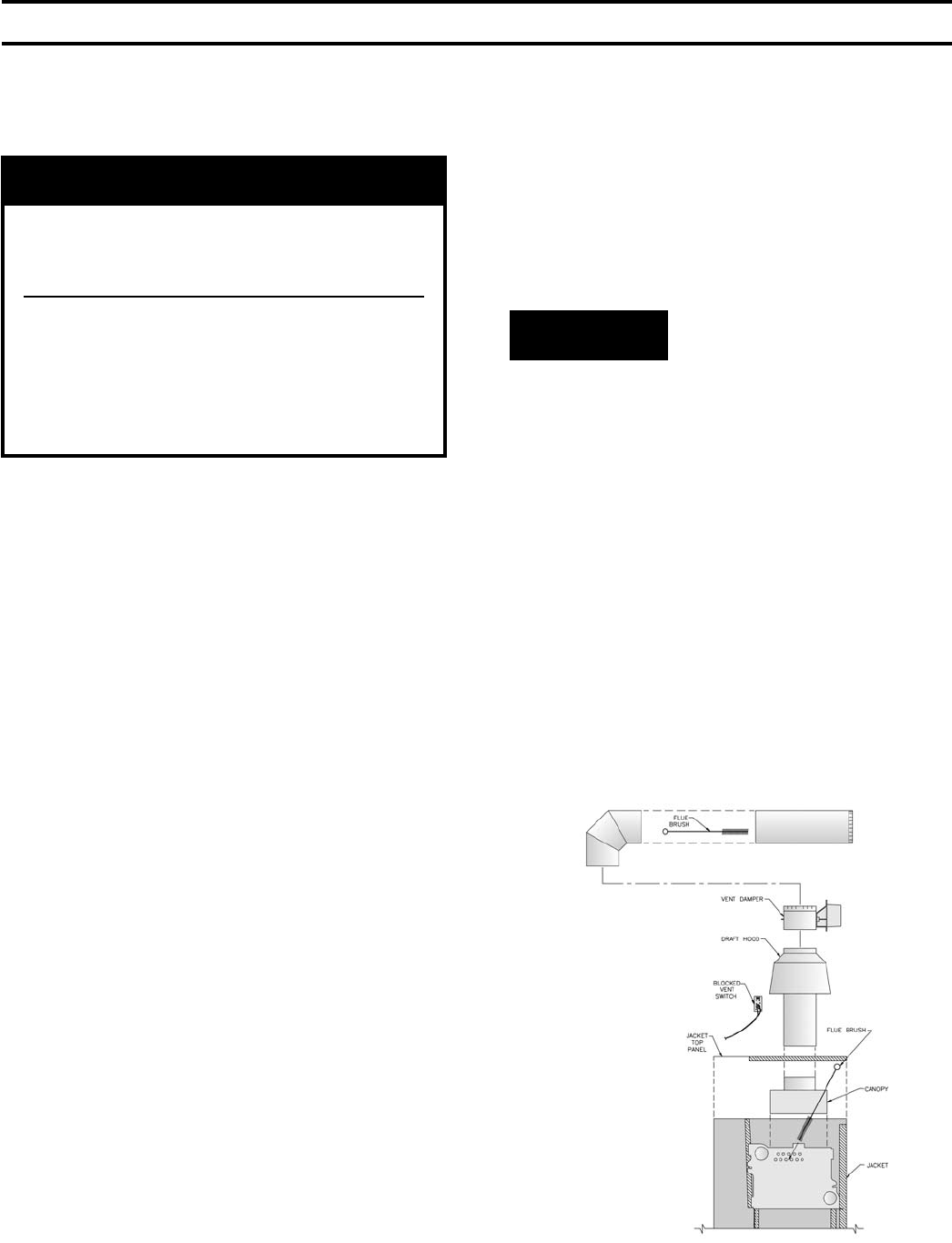

2. VENT SYSTEM. Vent system (see Figure 8 for typical

installation) should be checked annually for:

A. Obstructions.

B. Accumulations of soot.

C. Deterioration of vent pipe or vent accessories due to

condensation or other reasons.

D. Proper support - no sags, particularly in horizontal

runs.

E. Tightness of joints.

F. Proper vent damper operation - see Section II

Operating Instructions, paragraph 9.

G. Remove all accumulations of soot with wire brush

and vacuum, see Figure 29. Remove all

obstructions. Replace all deteriorated parts and

support properly. Seal all joints.

3. CLEANING BOILER FLUES, see Figure 29.

Flue passageways in the boiler sections should be

checked annually for any blockage or accumulation of

soot. To obtain access to ueways:

A. Remove vent pipe, damper (if boiler is so equipped),

blocked vent switch, and draft hood.

B. Remove sheet metal screws securing Jacket Top

Panel, lift panel and rotate about relief valve piping

until top of boiler is exposed.

C. Remove bolts securing Canopy to Boiler Sections.

Remove Canopy - ueways are now exposed.

D. Models with ue gas bafes only: Remove bafes

by lifting out of ueways.

Using ashlight, examine all ue passageways. If

passageways are free of soot and obstruction,

replace canopy (and ue gas bafes, if applicable),

and seal.

Reinstall Jacket Top Panel, draft hood, blocked vent

switch, damper (if boiler is so equipped), and vent

pipe.

If the ue passageways need cleaning, remove

burners as described in paragraph 4 below. Using

long handle wire or bristle ue brush and vacuum,

brush ueways thoroughly from top of boiler as

illustrated in Figure 29. Replace canopy and seal

with boiler putty. Reinstall Jacket Top Panel, draft

hood, blocked vent switch, damper (if boiler is so

equipped), and vent pipe.

NOTICE

4. BURNERS AND FIREBOX SHOULD BE CLEANED

ANNUALLY, AND IF NECESSARY ADJUSTED

ONCE A YEAR BY A QUALIFIED SERVICE

AGENCY.

A. TO REMOVE BURNERS FOR CLEANING,

CHANGING ORIFICE PLUGS, OR REPAIRS.

1. Remove the jacket front panel.

2. Disconnect pilot tubing at the gas valve. See

Figure 17.

3. Disconnect thermocouple (standing pilot) or pilot

lead wires (electronic ignition) at the gas valve.

4. 40mm burners only. Remove injection shield

assembly, where used. See Figure 30.

5. Remove wires to ame roll-out switch.

6. Remove the burner access panel.

7. Mark the location of the pilot main burner on the

manifold if the marking on manifold is missing

or obliterated.

Figure 29: Cleaning of Vent System

and Boiler Flues