18

II. Operating Instructions

1. MAIN BURNER CHECK - Check main burners to

see that they were not dislodged during shipment. Rear

of burners should be in the slots in the rear of burner

tray and the front of the burners should be seated

completely on the orices.

2. INITIAL START -

A. FILL ENTIRE HEATING SYSTEM WITH

WATER and vent air from system. Use the

following procedure on a Series Loop System

equipped with zone valves. (See Figure 3).

1. Close isolation valve in boiler supply piping.

2. Isolate all circuits by closing zone valves or

balancing valves.

3. Attach a hose to hose bib located just below

isolation valve in boiler supply piping. (Note -

Terminate hose in ve gallon bucket at a suitable

oor drain or outdoor area).

4. Starting with one circuit, open zone valve.

5. Open hose bib.

6. Open ll valve (Make-up water line should be

located directly above isolation valve in boiler

supply piping).

7. Allow water to overow from bucket until

discharge from hose is bubble free for 30

seconds.

8. Open zone valve to the second zone to be purged,

then close the rst. Repeat this step until all

zones have been purged, but always have one

zone open. At completion, open all zone valves.

9. Close hose bib, continue lling the system until

the pressure gauge reads 12 psi. Close ll valve.

(Note - If make-up water line is equipped with

pressure reducing valve, system will

automatically ll to 12 psi. Leave globe valve

open).

10. Open isolation valve in boiler supply piping.

11. Remove hose from hose bib.

B. Turn ROOM THERMOSTAT to lowest setting.

C. Be sure that gas to pilot and main burners has been

off for at least ve minutes and vent damper (if

used) has been in the open position.

D. Turn "OFF" the electric switch serving boiler.

E. Open valve on main gas line at meter.

F. PURGE AIR FROM GAS PIPING. This

procedure will vary with equipment furnished but in

all cases adequate ventilation must be provided

and no smoking or open ame permitted. To

determine which of the procedures outlined in

succeeding paragraphs is applicable, match sufx of

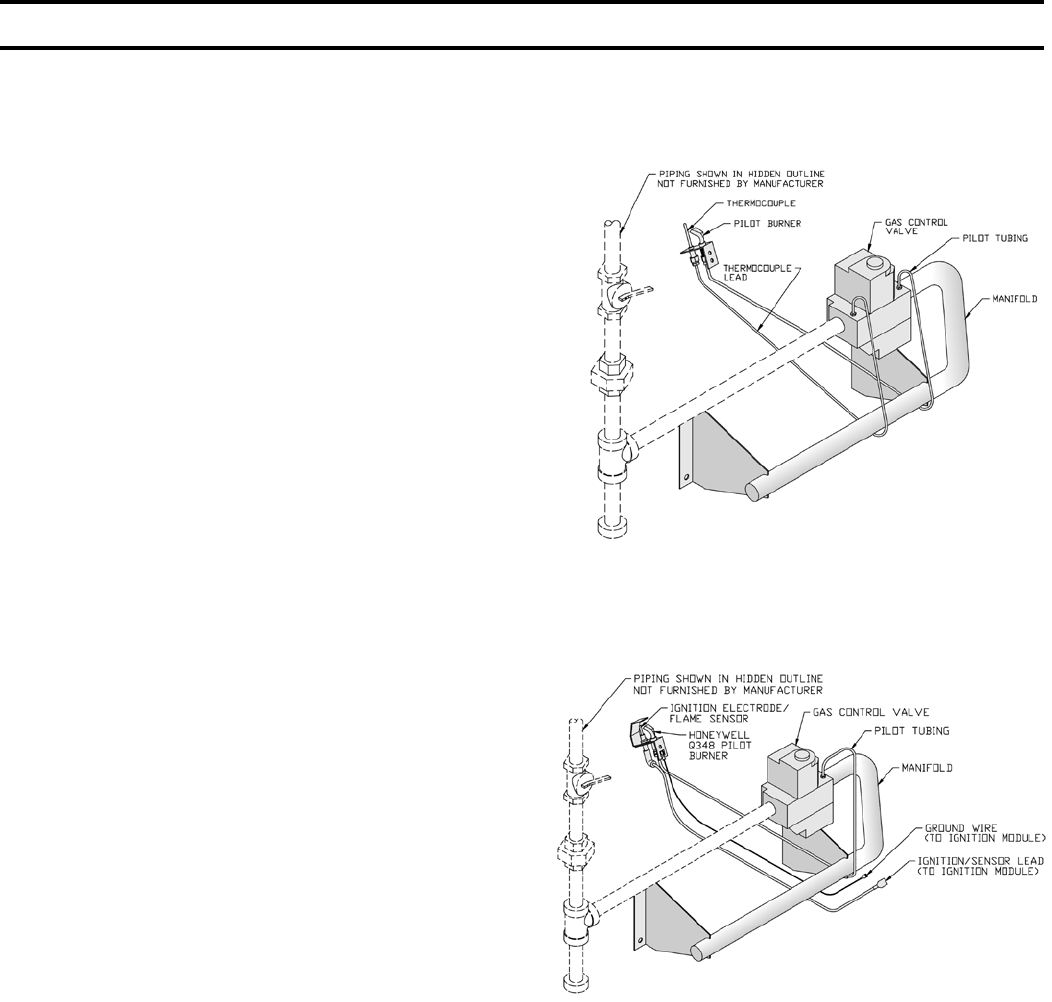

Figure 17: Schematic Pilot and Gas Piping

Continuous Ignition (Standing Pilot)

Figure 18: Schematic Pilot and Gas Piping

Electronic Ignition (EI)

boiler model found on Rating Label with paragraph

heading:

1. Standing Pilot Models (Sufx C):

a. Keep electric switch "OFF".

b. Open Manual Shut-off Valve upstream of

Combination Gas Valve.

c. Disconnect Pilot Tubing at gas valve (Purge

must not be into combustion chamber).

d. Turn Main Gas Knob on Combination Gas

Valve to "Pilot" Position. Depress and hold

in this position until purging is complete.

Turn Main Gas Knob to "off" position.

Safe lighting and other performance criteria were met with the gas manifold and control assembly provided on the boiler when the

boiler underwent tests specied in American National Standard for Gas-Fired Low-Pressure Steam and Hot Water Boilers, ANSI

Z21.13b-1994.