24

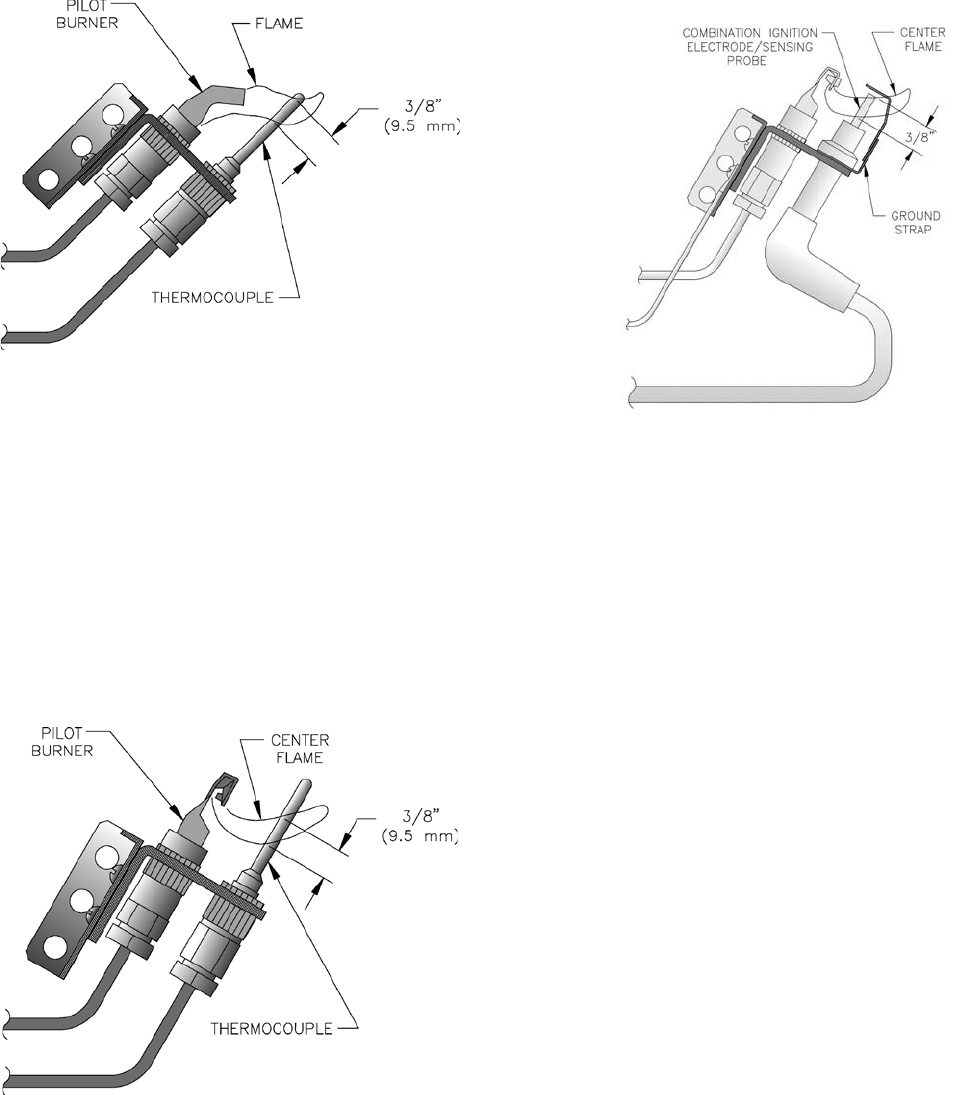

Figure 27: Typical Pilot Flame, Honeywell Q348A

The pilot produces a single ame. The ame should

be steady, medium hard blue enveloping 3/8 to a 1/2

inch of thermocouple.

B. Continuous Ignition (Standing Pilot)

Natural gas Models 207 with 40mm (1-9/16")

diameter burners and 208 through 210.

See Figure 26.

LP gas Models 203 through 210. See Figure 26.

The pilot produces three (3) ames. The center

ame should be steady, medium hard blue

enveloping 3/8 to a 1/2 inch of thermocouple.

Figure 25: Typical Pilot Flame, Honeywell Q350

Figure 26: Typical Pilot Flame, Honeywell Q327

C. Electronic Ignition (EI), see Figure 27.

The pilot produces three (3) ames. The center

ame should be steady, medium hard blue

enveloping 3/8 to a ½ inch of sensing probe.

7. CHECK THERMOSTAT OPERATION. Raise and

lower temperature setting as required to start and stop

burners.

8. CHECK HIGH LIMIT CONTROL. Jumper

Thermostat Terminals or Thermostat connections in

Limit Control. Allow burners to operate until shutdown

by limit. REMOVE JUMPER.

9. CHECK DAMPER OPERATION. Vent Damper must

be open when boiler is running. Le registre doit être

ouvert lorsque le brûleur principal de l’appareil

fonctionne. Start boiler, refer to instructions on damper

to determine if damper is in the full open position.

10. CHECK IGNITION SYSTEM SAFETY SHUT-OFF

DEVICE.

A. 24 volt-loosen thermocouple at gas valve.

B. Electronic Ignition - Remove pilot lead wires from

gas valve.

If burners do not shut down determine cause of

malfunction. Replace necessary items and check

operation.

11. COMBUSTION CHAMBER BURN-OFF

A. The mineral wool combustion chamber panels may

contain a cornstarch based binder that must be

burned out at installation to prevent odors during

subsequent boiler operation.

B. Ventilate the boiler room, set the high limit to its

maximum setting, set the thermostat to call for heat.

Allow the boiler to re for at least an hour or until

the odor from the cornstarch has dissipated.

C. Return the high limit and thermostat to their desired

settings.