—19—

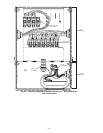

C. Wiring the Room Controller

The room controller is capable of controlling from 1 to 6 fan

coil units. The total run length of the wire connecting the

room controller to the fan coil units should be kept to under

500 feet. Wire the room controller to the unit using daisy

chain wiring. See Fig. 28. The room controller connects to

the receiver board connection on the electronic board inside

the unit.

Wiring the Power Connection to the Room Controller

The thermostat will be powered by unregulated nominal

12.5 volts DC (10V min to 20V max) which is provided by the

electronic board inside the unit. The power consumption will

be 50 mA 12.5 volts DC. For applications where more than

one fan coil unit is to be controlled, the fan coil unit closest to

the room controller will be the only one that supplies power

to the room controller. The control should be protected from

damage in case of accidental wiring of power, ground and

signal wiring occurs.

Wiring the Room Controller to the Indoor Unit

Loosen the screws of terminals P (DC Power), G (GROUND)

and C (SIGNAL) on the indoor unit and room controller

terminal blocks. Refer to Fig. 29 and connect the indoor unit

terminal block to the room controller terminal block.

INSTALLATION OPTIONS

The 619FNF, FNQ units can be used to cool an adjacent

room or for fresh-air ventilation. Plan the installation care-

fully. Measure carefully and follow acceptable building prac-

tices and the National Electric Code (NEC).

I. FRESH AIR INTAKE

1. Using Fig. 30, locate and remove the factory-installed

insulation from the side of the unit where the

pre-punched knockouts are located.

2. Remove the pre-punched knockouts for fresh air

intake. Refer to Fig. 30. Be careful not to damage

internal parts such as the heat exchanger coil.

3. If installing a 619FNF018 unit, install baffle. Refer to

Fig. 30.

4. Install ductwork using field-supplied, insulated flex

duct, or insulated sheet metal suitable for working

temperatures up to 140 F. Conduits can be of flexible

polyester (with spiral core) or corrugated aluminum,

externally covered with anti-condensate material

(fiberglass from

1

/

4

in. to 1 in. thickness).

5. Use Fig. 31 to determine the allowable static pres-

sure loss for the ductwork airflow. The ductwork

design must not exceed this value or the job airflow

requirements will not be met.

6. Use a field-supplied fan if airflow does not meet job

requirements. The field-supplied fan motor for out-

side air intake must be controlled by a bipolar ON/

OFF switch with safety fuses.

IMPORTANT: Ventilated air must not exceed 10% of the total

airflow or problems with operation will result. If the venti-

lated air surpasses 10% of the total airflow, a field-supplied

primary air treatment system with separate deflectors is

recommended.

7. Install an air inlet grille with filter inspection port to

prevent dust and dirt from entering and fouling the

indoor unit heat exchanger. Filter installation also

makes the installation of a duct closing damper dur-

ing shutdown periods unnecessary.

8. All non-insulated ducts must be covered with anti-

condensate insulation (such as expanded neoprene,

1

/

4

in. thickness).

II. CONDITIONED AIR SUPPLY TO ADJACENT ROOM

Air supply to an adjacent room requires that the outlet corre-

sponding with the duct is closed, using the air supply outlet

obstruction accessory kit.

NOTE: The accessory kit cannot be used in units equipped

with an electric heater.

An air inlet grille must be fitted (if possible near the floor)

between the air conditioned room (where the unit is situ-

ated) and the adjacent room or, alternatively, the door must

be undercut, as shown in Fig. 30. The duct lengths can be

calculated in accordance with Fig. 30, also taking into

account the pressure drop through air diffusers and fresh air

filters.

IMPORTANT: DO NOT use active carbon or electrostatic

filter kits for ducts towards adjacent rooms.

P

G

C

P

G

C

Indoor unit

Room Controller

Diagram 1

Main electronic card

4 pins terminal block placed on external

control box

Wires supplied by the installer

Terminal block in the Room Controller

A

B

Red

Black

White

Remote connector

(J5) 5 pins

A

B

Fig. 29 — Wiring the Room Controller to

the Indoor Unit

REMOTE

FCU 6

FCU 3

FCU 2

FCU 1

Fig. 28 — Room Controller Daisy Chain Wiring

(Multidrop)