—62—

II. LUBRICATION

A. Compressors

Each compressor is charged with the correct amount of oil at

the factory.

B. Fan-Motor Bearings

Fan-motor bearings are of the permanently lubricated type.

No further lubrication is required. No lubrication of

condenser-fan or evaporator-fan motors is required.

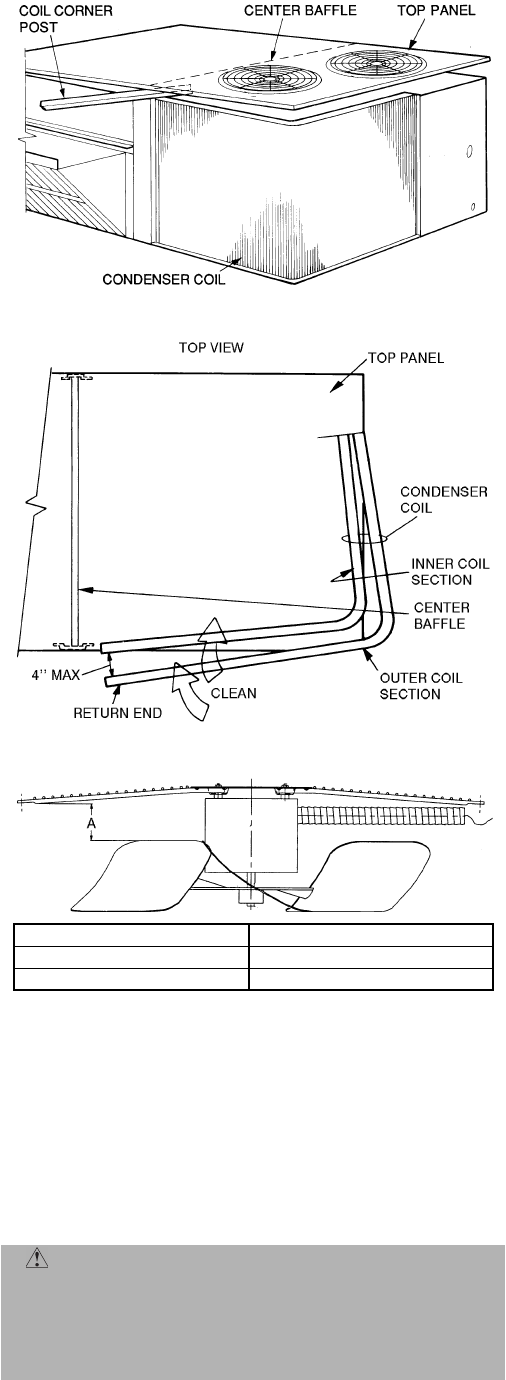

III. CONDENSER FAN ADJUSTMENT (Fig. 40)

1. Shut off unit power supply and tag disconnect.

2. Remove condenser-fan assembly (grille, motor, motor

cover, and fan) and loosen fan hub setscrews.

3. Adjust fan height as shown in Fig. 40.

4. Tighten setscrews and replace condenser-fan

assembly.

IV. BLOWER BELT ADJUSTMENT

Inspect blower belt for wear, proper belt tension, and pulley

alignment as conditions require or at the beginning of each

heating and air conditioning season. Refer to Step 9 —

Adjust Evaporator Fan Speed on page 27 for adjustment and

alignment procedures.

V. MANUAL OUTDOOR-AIR DAMPER

If outdoor-air damper blade is required, see Manual

Outdoor-Air Damper section on page 17.

VI. ECONOMIZER ADJUSTMENT

Refer to Optional EconoMi$er+ section on page 18.

VII. CONDENSER COIL GRILLE

Condenser coil grille is shipped factory-installed. No adjust-

ments are required.

VIII. HIGH-PRESSURE SWITCH

Located on the compressor’s hot gas line is a high-pressure

switch. This switch opens at 428 psig and closes at 320 psig.

No adjustment is necessary. Refer to Tables 1A and 1B.

NOTE: There is no Schrader core in the valve below the high-

pressure switch.

IX. LOSS-OF-CHARGE SWITCH

Located on the condenser’s liquid line is a low-pressure

switch which functions as a loss-of-charge switch. This

switch contains a Schrader core depressor. This switch opens

at 7 psig and closes at 22 psig. No adjustment is necessary.

Refer to Tables 1A and 1B.

X. FREEZESTAT

Located on the “hair pin” end of the evaporator coil is a

bimetal temperature sensing switch. This switch protects

the evaporator coil from freeze-up due to lack of airflow. The

switch opens at 30 F and closes at 45 F. No adjustment is

necessary. Refer to Tables 1A and 1B.

XI. CHECKING AND ADJUSTING REFRIGERANT CHARGE

The refrigerant system is fully charged with R-22 refriger-

ant, tested, and factory-sealed. Unit must operate in Cooling

mode a minimum of 10 minutes before checking charge.

NOTE: Adjustment of the refrigerant charge is not required

unless the unit is suspected of not having the proper R-22

charge.

A superheat charging chart is attached to the outside of the

service access panel. The chart includes the required suction

line temperature at given suction line pressures and outdoor

ambient temperatures.

An accurate superheat, thermocouple-type or thermistor-

type thermometer, and a gage manifold are required when

using the superheat charging method for evaluating the unit

charge. Do not use mercury or small dial-type thermometers

because they are not adequate for this type of measurement.

CAUTION: When evaluating the refrigerant

charge, an indicated adjustment to the specified fac-

tory charge must always be very minimal. If a substan-

tial adjustment is indicated, an abnormal condition

exists somewhere in the cooling system, such as insuf-

ficient airflow across either coil or both coils.

Fig. 38 — Propping Up Top Panel

Fig. 39 — Separating Coil Sections

Fig. 40 — Condenser-Fan Adjustment

580F UNIT VOLTAGE FAN HEIGHT “A” (in.)

208/230 V 2.75

460 V and 575 V 3.50