Copyright 2006 Bryant Heating & Cooling Systems Printed in U.S.A. CL-1 CATALOG NO. 04-53580003-01

CUT ALONG DOTTED LINE

CUT ALONG DOTTED LINE

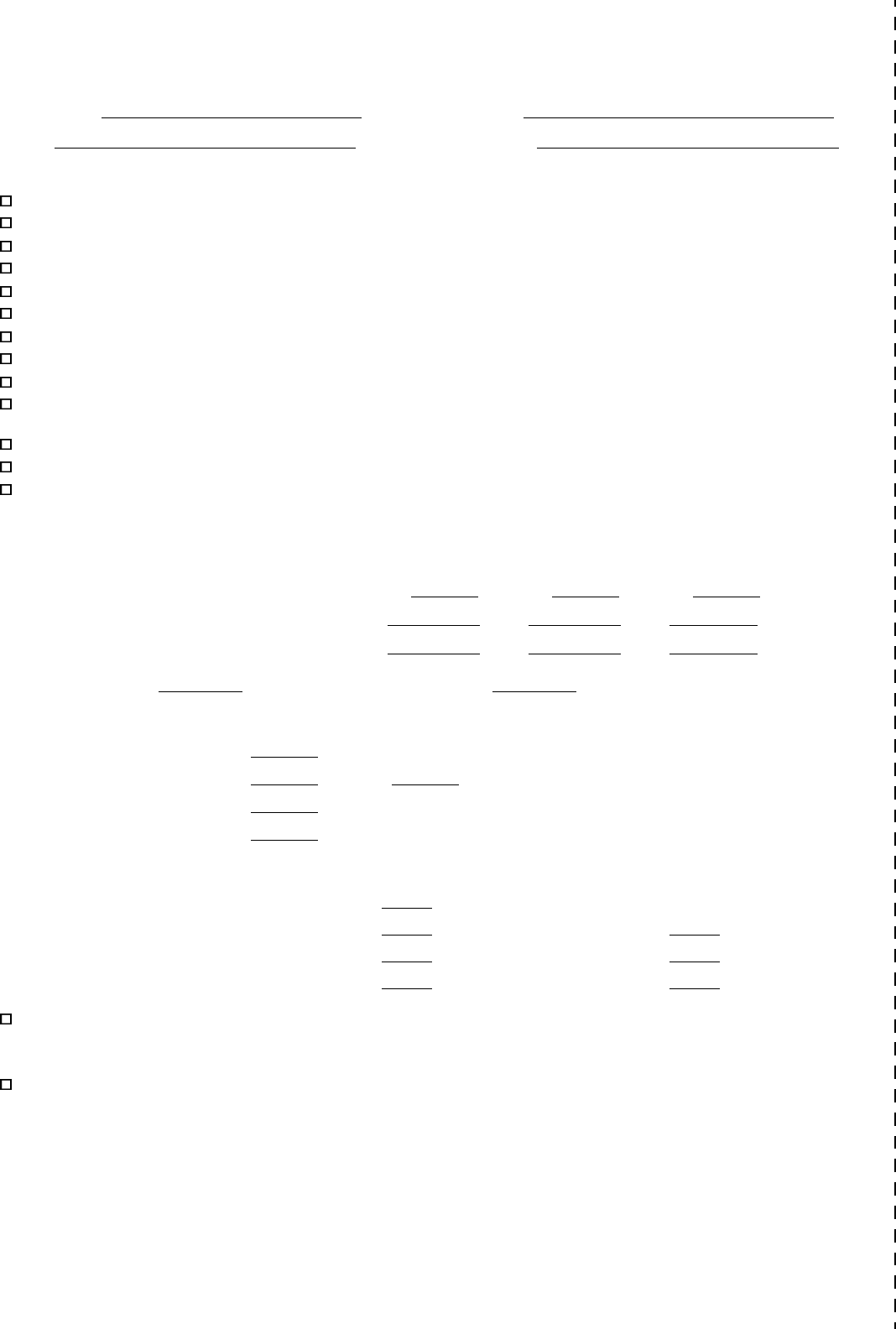

START-UP CHECKLIST

I. PRE-START-UP

VERIFY THAT ALL PACKING MATERIALS HAVE BEEN REMOVED FROM UNIT

VERIFY INSTALLATION OF INDOOR FAN MOTOR ADJUSTMENT BOLT AND PLATE

VERIFY INSTALLATION OF OUTDOOR-AIR HOOD

VERIFY INSTALLATION OF FLUE HOOD AND WIND BAFFLE

VERIFY THAT CONDENSATE CONNECTION IS INSTALLED PER INSTRUCTIONS

VERIFY THAT ALL ELECTRICAL CONNECTIONS AND TERMINALS ARE TIGHT

CHECK GAS PIPING FOR LEAKS

CHECK THAT FILTERS AND SCREENS ARE CLEAN AND IN PLACE

VERIFY THAT UNIT IS LEVEL

CHECK FAN WHEEL AND PROPELLER FOR LOCATION IN HOUSING/ORIFICE, AND VERIFY SETSCREW

IS TIGHT

VERIFY THAT FAN SHEAVES ARE ALIGNED AND BELTS ARE PROPERLY TENSIONED

VERIFY THAT SCROLL COMPRESSOR IS ROTATING IN THE CORRECT DIRECTION

VERIFY THAT CRANKCASE HEATER HAS BEEN ENERGIZED FOR 24 HOURS

II. START-UP

ELECTRICAL

SUPPLY FAN AMPS

EXHAUST FAN AMPS

TEMPERATURES

OUTDOOR-AIR TEMPERATURE

F DB (Dry-Bulb)

RETURN-AIR TEMPERATURE F DB F WB (Wet-Bulb)

COOLING SUPPLY AIR

F

GAS HEAT SUPPLY AIR

F

PRESSURES

VERIFY REFRIGERANT CHARGE USING CHARGING CHART ON PAGE 37.

GENERAL

ECONOMI$ERIV MINIMUM VENT AND CHANGEOVER SETTINGS TO JOB REQUIREMENTS

MODEL NO.:

SERIAL NO.:

DATE: TECHNICIAN:

SUPPLY VOLTAGE L1-L2 L2-L3 L3-L1

COMPRESSOR AMPS — COMPRESSOR NO. 1 L1 L2 L3

— COMPRESSOR NO. 2 L1 L2 L3

GAS INLET PRESSURE IN. WG

GAS MANIFOLD PRESSURE STAGE NO. 1

IN. WG STAGE NO. 2 IN. WG

REFRIGERANT SUCTION CIRCUIT NO. 1

PSIG CIRCUIT NO. 2 PSIG

REFRIGERANT DISCHARGE CIRCUIT NO. 1

PSIG CIRCUIT NO. 2 PSIG