—37—

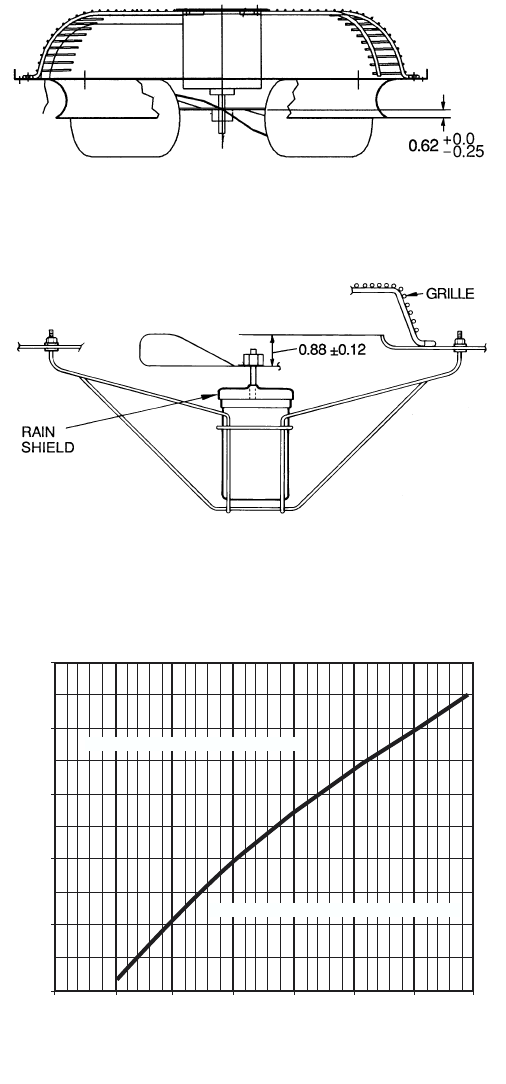

C. To Use the Cooling Charging Chart

Use the above temperature and pressure readings, and find

the intersection point on the cooling charging chart. If inter-

section point on chart is above line, add refrigerant. If inter-

section point on chart is below line, carefully recover some of

the charge. Recheck suction pressure as charge is adjusted.

NOTE: Indoor-air cfm must be within normal operating

range of unit. All outdoor fans must be operating.

The TXV (thermostatic expansion valve) is set to maintain

between 15 and 20 degrees of superheat at the

compressors. The valves are factory set and should not

require re-adjustment.

D. Perfect Humidity™ System Charging

The system charge for units with the Perfect Humidity

option is greater than that of the standard unit alone. The

charge for units with this option is indicated on the unit

nameplate drawing. To charge systems using the Perfect

Humidity dehumidification package, fully evacuate, recover,

and re-charge the system to the nameplate specified charge

level. To check or adjust refrigerant charge on systems using

the Perfect Humidity dehumidification package, charge per

the standard subcooling charts. The subcooler MUST be

deenergized to use the charging charts. The charts reference

a liquid pressure (psig) and temperature at a point between

the condenser coil and the subcooler coil. A tap is provided

on the unit to measure liquid pressure entering the sub-

cooler (leaving the condenser).

IX. GAS VALVE ADJUSTMENT

A. Natural Gas

The gas valve opens and closes in response to the thermostat

or limit control.

When power is supplied to valve terminals D1 and C2, the

main valve opens to its preset position.

The regular factory setting is stamped on the valve body

(3.3 in. wg).

To adjust regulator:

1. Set thermostat at setting for no call for heat.

2. Turn main gas valve to OFF position.

3. Remove

1

/

8

-in. pipe plug from manifold or gas valve

pressure tap connection. Install a suitable pressure-

measuring device.

4. Set main gas valve to ON position.

5. Set thermostat at setting to call for heat.

6. Remove screw cap covering regulator adjustment

screw (see Fig. 43).

7. Turn adjustment screw clockwise to increase pres-

sure or counterclockwise to decrease pressure.

8. Once desired pressure is established, set thermostat

setting for no call for heat, turn off main gas valve,

remove pressure-measuring device, and replace

1

/

8

-in. pipe plug and screw cap.

X. MAIN BURNERS

For all applications, main burners are factory set and should

require no adjustment.

A. Main Burner Removal

1. Shut off (field-supplied) manual main gas valve.

2. Shut off power to unit.

3. Remove unit control box access panel, burner section

access panel, and center post (Fig. 4-6).

4. Disconnect gas piping from gas valve inlet.

5. Remove wires from gas valve.

6. Remove wires from rollout switch.

7. Remove sensor wire and ignitor cable from IGC

board.

8. Remove 2 screws securing manifold bracket to

basepan.

9. Remove 2 screws that hold the burner support plate

flange to the vestibule plate.

10. Lift burner assembly out of unit.

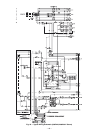

NOTE: Dimensions are in inches.

Fig. 40 — Condenser Fan Adjustment, 580F180, 210, 300

NOTE: Dimensions are in inches.

Fig. 41 — Condenser Fan Adjustment, 580F240

50

40

100

150

200

250

300

350

400

60

80

100

120

140

ALL OUTDOOR FANS MUST BE OPERATING

LIQUID PRESSURE AT LIQUID VALVE (PSIG)

LIQUID TEMPERATURE AT LIQUID VALVE (DEG F)

BOTH CIRCUITS

REDUCE CHARGE IF BELOW CURVE

ADD CHARGE IF ABOVE CURVE

Fig. 42 — Cooling Charging Chart