—11—

III. STEP 3 — FIELD FABRICATE DUCTWORK

Secure all ducts to building structure. Use flexible duct con-

nectors between unit and ducts as required. Insulate and

weatherproof all external ductwork, joints, and roof openings

with counter flashing and mastic in accordance with applica-

ble codes.

Ducts passing through an unconditioned space must be

insulated and covered with a vapor barrier.

IV. STEP 4 — MAKE UNIT DUCT CONNECTIONS

Unit is shipped for thru-the-bottom duct connections. Duct-

work openings are shown in Fig. 1 and 4-6. Duct connections

are shown in Fig. 7. Field-fabricated concentric ductwork

may be connected as shown in Fig. 8 and 9. Attach all duct-

work to roof curb and roof curb basepans.

V. STEP 5 — INSTALL FLUE HOOD AND WIND BAFFLE

Flue hood and wind baffle are shipped secured under main

control box. To install, secure flue hood to access panel. See

Fig. 10. The wind baffle is then installed over the flue hood.

NOTE: When properly installed, flue hood will line up with

combustion fan housing. See Fig. 11.

VI. STEP 6 — TRAP CONDENSATE DRAIN

See Fig. 12 for drain location. One

3

/

4

-in. half coupling is pro-

vided inside unit evaporator section for condensate drain

connection. An 8

1

/

2

-in. x

3

/

4

-in. diameter and 2-in. x

3

/

4

-in.

diameter pipe nipple, coupled to standard

3

/

4

-in. diameter

elbows, provide a straight path down through hole in unit

base rails (see Fig. 13). A trap at least 4-in. deep must be

used.

NOTE: Do not drill in this area; damage to basepan may result in water

leak.

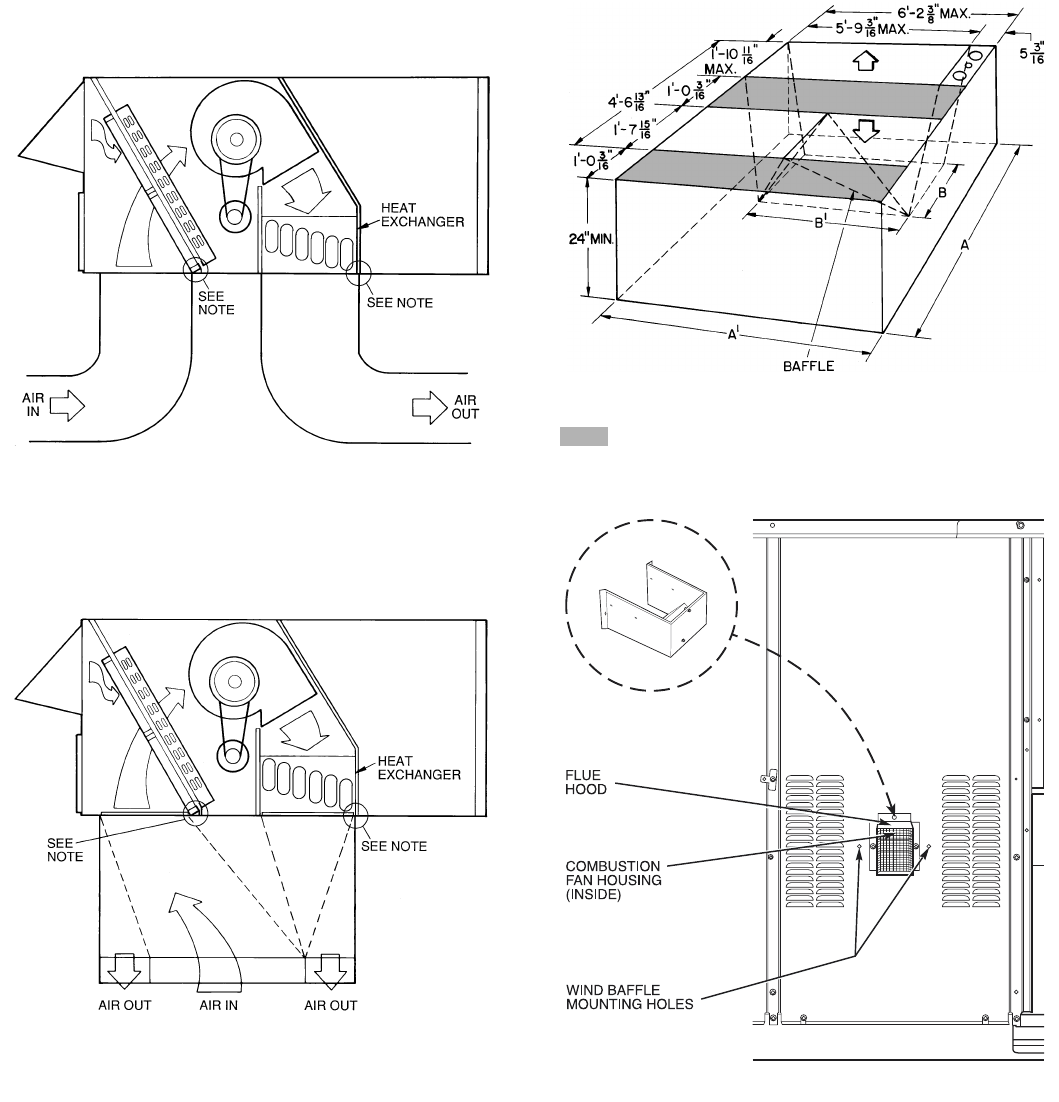

Fig. 7 — Air Distribution — Thru-the-Bottom

NOTE: Do not drill in this area; damage to basepan may result in water

leak.

Fig. 8 — Concentric Duct Air Distribution

WIND

BAFFLE

NOTE: Dimensions A, A′, B, and B′ are obtained from field-supplied

ceiling diffuser.

Shaded areas indicate block-off panels.

Fig. 9 — Concentric Duct Details

Fig. 10 — Flue Hood Location