—35—

E. Condenser Coil

Clean condenser coil annually and as required by location

and outdoor-air conditions. Inspect coil monthly — clean as

required.

F. Condensate Drain

Check and clean each year at start of cooling season. In

winter, keep drains and traps dry.

G. Filters

Clean or replace at start of each heating and cooling season,

or more often if operating conditions require. Refer to Table 1

for type and size.

NOTE: The 580F300 unit requires industrial grade throw-

away filters capable of withstanding face velocities up to

625 fpm. Ensure that replacement filters for the 580F300

units are rated for 625 fpm.

H. Outdoor-Air Inlet Screens

Clean screens with steam or hot water and a mild detergent.

Do not use throwaway filters in place of screens.

II. LUBRICATION

A. Compressors

Each compressor is charged with the correct amount of oil at

the factory. Conventional white oil (Sontex 200LT) is used.

White oil is compatible with 3GS oil, and 3GS oil may be

used if the addition of oil is required. See compressor name-

plate for original oil charge. A complete recharge should be

four ounces less than the original oil charge. When a

compressor is exchanged in the field it is possible that a

major portion of the oil from the replaced compressor may

still be in the system. While this will not affect the reliability

of the replacement compressor, the extra oil will add rotor

drag and increase power usage. To remove this excess oil, an

access valve may be added to the lower portion of the suction

line at the inlet of the compressor. The compressor should

then be run for 10 minutes, shut down and the access valve

opened until no oil flows. This should be repeated twice to

make sure the proper oil level has been achieved.

B. Fan Shaft Bearings

Lubricate bearings at least every 6 months with suitable

bearing grease. Extended grease line is provided for far side

fan bearing (opposite drive side). Typical lubricants are

given below:

*Preferred lubricant because it contains rust and oxidation inhibitors.

C. Condenser and Evaporator-Fan Motor Bearings

The condenser and evaporator-fan motors have permanently

sealed bearings, so no field lubrication is necessary.

III. EVAPORATOR FAN PERFORMANCE ADJUSTMENT

(Fig. 38 and 39)

Fan motor pulleys are factory set for speed shown in Table 1.

To change fan speeds:

1. Shut off unit power supply.

2. Loosen nuts on the 2 carriage bolts in the motor

mounting base. Install jacking bolt and plate under

motor base (bolt and plate are shipped in installer’s

packet). Using bolt and plate, raise motor to top of

slide and remove belt. Secure motor in this position

by tightening the nuts on the carriage bolts.

3. Loosen movable-pulley flange setscrew (see Fig. 38).

4. Screw movable flange toward fixed flange to increase

speed and away from fixed flange to decrease speed.

Increasing fan speed increases load on motor. Do not

exceed maximum speed specified in Table 1.

See Table 21 for air quantity limits.

5. Set movable flange at nearest keyway of pulley hub

and tighten setscrew. (See Table 1 for speed change

for each full turn of pulley flange.)

6. Replace and tighten belts. See Belt Tension Adjust-

ment section below.

To align fan and motor pulleys:

1. Loosen fan pulley setscrews.

2. Slide fan pulley along fan shaft.

3. Make angular alignment by loosening motor from

mounting plate.

IV. EVAPORATOR FAN SERVICE AND REPLACEMENT

The 580F units use a fan motor mounting system that fea-

tures a slide-out motor mounting plate. See Fig. 39. To

replace or service the motor, slide out the bracket.

1. Remove the evaporator-fan access panel and the

heating control access panel.

2. Remove the center post (located between the evapora-

tor fan and heating control access panels) and all

screws securing it.

3. Loosen nuts on the 2 carriage bolts in the motor

mounting base.

4. Using jacking bolt under motor base, raise motor to

top of slide and remove belt. Secure motor in this

position by tightening the nuts on the carriage bolts.

MANUFACTURER LUBRICANT

Texaco Regal AFB-2*

Mobil Mobilplex EP No. 1

Sunoco Prestige 42

Texaco Multifak 2

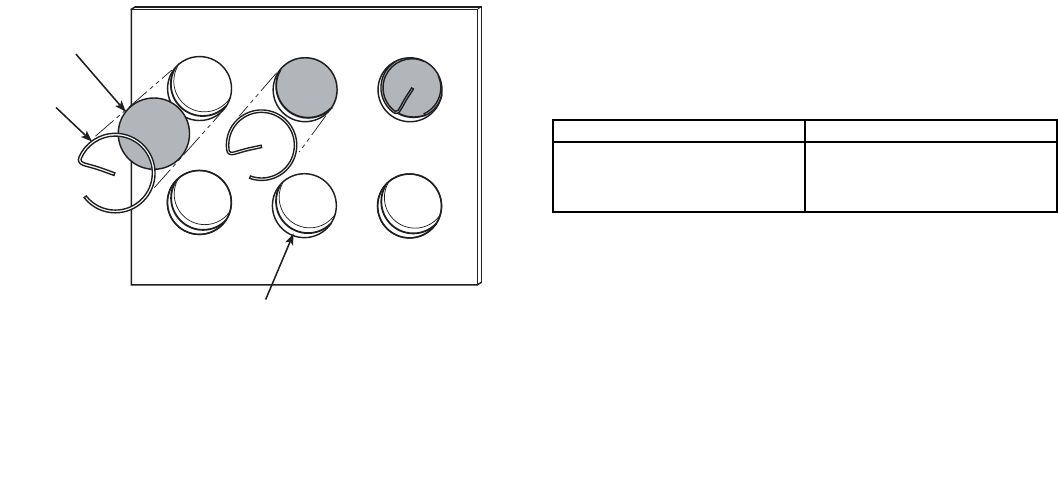

CERAMIC

BAFFLE

CLIP

HEAT EXCHANGER

TUBES

NOTE: One baffle and clip will be in each upper tube of the heat

exchanger.

Fig. 37 — Removing Heat Exchanger Ceramic

Baffles and Clips