21

APPLICATION DATA

1.

CONDENSATE DRAIN PAN —

A sloped condensate drain

pan is supplied on all units. The condensate drain pan must

be externally trapped. Condensate drains are located on

both the bottom and end of the unit. The bottom drain can

be used for thru-the-curb connections.

2.

DUCTWORK —

All ductwork must be attached to flanges. If

no flanges are present, they must be field supplied. Secure

vertical discharge ductwork to roof curb. For horizontal dis-

charge applications, attach ductwork to flanges. Field-

supplied flanges can be attached to horizontal discharge

openings and all ductwork attached to flanges.

3.

THRU-THE-BOTTOM SERVICE CONNECTIONS —

Thru-

the-bottom connections allow field power wires and control

wires to enter through the basepan.

4.

THERMOSTAT —

Use of 2-stage cooling thermostat is

recommended for all units equipped with economizer.

5.

HEATING-TO-COOLING CHANGEOVER —

All units are

automatic changeover from heating to cooling when auto-

matic changeover thermostat and subbase are used.

6.

AIRFLOW —

Units are draw-thru on cooling and blow-thru

on heating.

7.

MAXIMUM AIRFLOW —

To minimize possibility of conden-

sate blow-off from evaporator, airflow through units should

not exceed 500 cfm/ton.

8.

MINIMUM AIRFLOW —

Minimum airflow for cooling is

300 cfm/ton for unit sizes 036-240, 280 cfm/ton for size 300.

9.

MINIMUM AMBIENT OPERATING TEMPERATURE —

Minimum operating temperature for standard 036-150 units

is 25 F, for standard 155-300 units is 40 F. With accessory

Motormaster® or Motormaster IV control, units can operate

at outdoor temperatures down to –20 F.

10.

MAXIMUM OPERATING OUTDOOR-AIR TEMPERATURE

—

Maximum outdoor-air operating temperature for cooling

is 125 F (115 F for 558F036-150 units).

11.

MOTOR DATA —

Due to Bryant’s internal unit design (draw-

thru over the motor), air path, and specially designed

motors, the full horsepower (maximum continuous bhp)

listed in the Physical Data table and in each Fan Perfor-

mance table can be utilized with extreme confidence.

Using Bryant motors to the values listed in the Physical

Data, Fan Performance, and Evaporator-Fan Motor Data

tables

will not

result in nuisance tripping or premature motor

failure. In addition, the unit warranty will not be affected.

12.

PERFECT HUMIDITY™ DEHUMIDIFICATION PACKAGE

—

This option provides greater dehumidification by further

subcooling the hot liquid refrigerant leaving the condenser

coil. The Perfect Humidity package consists of a subcooling

coil located on the leaving-air side of the evaporator coil.

The location of the coil in the indoor airstream enhances the

latent capacity of the rooftop units by up to 40%.

Many buildings suffer damage or have poor indoor-air qual-

ity due to overly humid conditions. Building humidity must

be controlled for the following reasons:

a.

INDOOR-AIR QUALITY —

Humidity is a major factor in

the growth and propagation of mold and mildew in a

building. The mold and mildew can spread quickly and

grow in carpets and ductwork and on walls, and often

causes cases of sick building syndrome. This syndrome

can lead to employee absenteeism due to illness, lower

worker productivity, and increased health care costs. The

American Society of Heating, Refrigeration, and Air Con-

ditioning Engineers (ASHRAE) recommends that relative

humidity levels in buildings be maintained below 70%.

b.

COMFORT LEVELS —

High humidity levels cause the

occupied space to become uncomfortable, because

humidity interferes with the body’s natural cooling pro-

cess (evaporation at the skin surface).

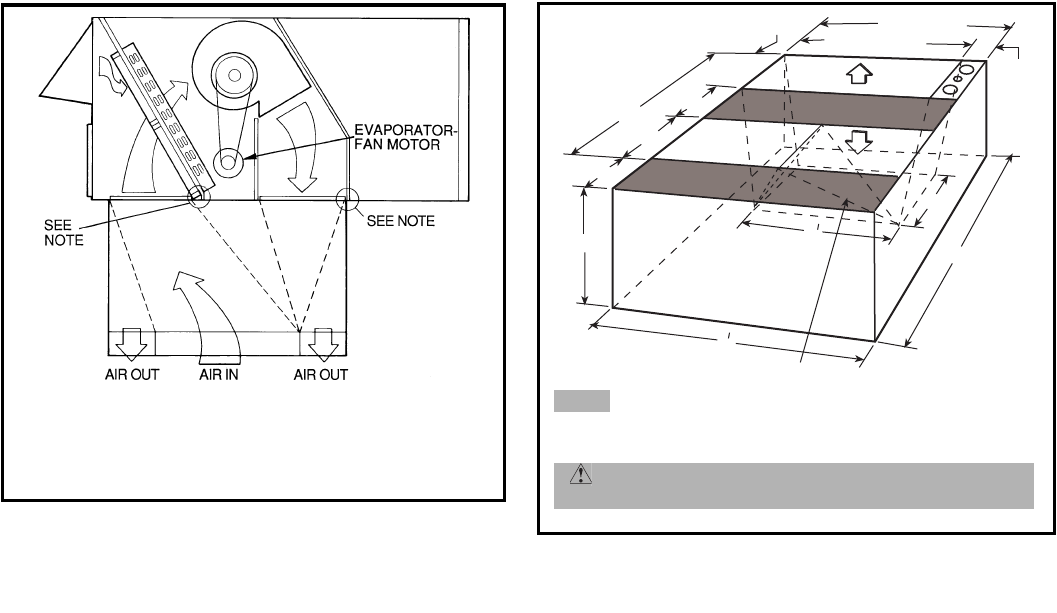

Concentric Duct Distribution —

Unit Sizes 155-300

NOTE:

1. Do not drill in this area, damage to basepan may result in

water leak.

2. A 90-degree elbow must be provided in the supply ductwork

to comply with UL (Underwriters’ Laboratories) codes for use

with electric heat.

6'-2 3/8'' MAX.

5'-9 3/16'' MAX.

5 3/16''

B

A

BAFFLE

A

B

24'' MIN.

1'-0 3/16''

1'-7 15/16''

4'-6 13/16''

1'-0 3/16''

1'-10 11/16''

MAX.

Shaded area indicates block-off panels.

NOTE:

Dimensions A, A

′

and B, B

′

are obtained from field-supplied

ceiling diffuser.

CAUTION:

Concentric ducts may only be installed on units

without electric heat. Personal injury or unit damage may result.

Concentric Duct Details — Unit Sizes 155-300