121

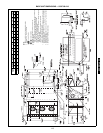

PERFORMANCE DATA (cont)

COOLING CAPACITIES (cont)

LEGEND

NOTES:

1. Direct interpolation is permissible. Do not extrapolate.

2. The following formulas may be used:

Where: h

ewb

= Enthalpy of air entering evaporator coil

3. The SHC is based on 80 F edb temperature of air entering evaporator coil.

Below 80 F edb, subtract (corr factor x cfm) from SHC.

Above 80 F edb, add (corr factor x cfm) to SHC

.

Interpolation is permissible.

Correction Factor = 1.10 x (1 – BF) x (edb – 80).

559F180 (15 TONS) — UNITS WITH PERFECT HUMIDITY™ OPTION

Temp (F)

Air Entering

Condenser

(Edb)

Evaporator Air Quantity — Cfm/BF

4500/0.12 5250/0.14 6000/0.15 6750/0.18 7500/0.18

Evaporator Air — Ewb (F)

62 67 72 62 67 72 62 67 72 62 67 72 62 67 72

75

TC

— 183 202 — 185 207 — 190 211 — 196 216 181 198 218

SHC

— 106 82 — 114 87 — 122 92 — 129 96 169 138 100

kW

— 14.0 14.6 — 14.4 14.8 — 14.6 14.9 — 14.5 15.0 14.1 14.6 15.1

85

TC

— 174 192 — 178 196 — 182 200 171 187 204 173 189 207

SHC

— 98 74 — 106 78 — 113 82 151 120 86 158 127 91

kW

— 15.2 15.8 — 15.2 15.9 — 15.4 15.9 15.2 15.8 16.0 15.2 15.8 16.3

95

TC

— 164 181 — 168 185 — 171 190 160 174 192 160 178 194

SHC

— 90 65 — 98 69 — 104 73 142 111 77 150 118 80

kW

— 16.2 16.7 — 16.4 16.8 — 16.4 17.0 16.1 16.3 17.1 16.1 16.7 17.1

105

TC

— 153 168 — 158 174 — 161 177 148 163 179 151 165 181

SHC

— 82 56 — 89 60 — 96 64 131 102 67 141 108 71

kW

— 17.2 17.8 — 17.4 18.1 — 17.5 18.1 17.2 17.6 18.0 17.2 17.6 18.3

115

TC

— 142 156 — 145 161 — 148 163 137 150 166 139 152 167

SHC

— 73 47 — 79 50 — 85 54 122 91 57 130 97 60

kW

— 18.3 18.8 — 18.6 19.0 — 18.7 19.1 18.2 18.8 19.3 18.4 18.9 19.4

118

TC

— 138 152 — 142 156 — 144 159 133 146 161 135 148 163

SHC

— 70 44 — 76 47 — 82 50 119 87 53 126 93 56

kW

— 18.7 19.2 — 18.8 19.4 — 19.0 19.5 18.6 19.0 19.7 18.6 19.2 19.7

120

TC

— 136 150 — 140 ——142 — 131 144 — 133 146 160

SHC

— 68 42 — 74 —— 80 — 117 85 — 124 91 54

kW

— 18.9 19.3 — 19.0 ——19.1 — 18.6 19.2 — 18.8 19.3 19.8

125

TC

——————————————152

SHC

—————————————— 48

kW

——————————————20.3

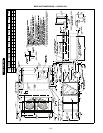

559F216 (18 TONS) — UNITS WITH PERFECT HUMIDITY OPTION

Temp (F)

Air Entering

Condenser

(Edb)

Evaporator Air Quantity — Cfm/BF

5400/0.095 6000/0.105 7000/0.12 8000/0.14 9000/0.15

Evaporator Air — Ewb (F)

62 67 72 62 67 72 62 67 72 62 67 72 62 67 72

75

TC

— 201 221 — 204 226 — 210 231 — 213 235 196 215 237

SHC

— 120 92 — 126 96 — 137 102 — 147 108 196 157 114

kW

— 14.7 15.3 — 14.8 15.5 — 15.0 15.7 — 15.2 15.8 14.8 15.3 15.9

85

TC

— 191 212 — 195 215 — 200 221 — 203 224 186 205 227

SHC

— 112 83 — 118 87 — 129 94 — 138 100 186 148 105

kW

— 16.3 16.6 — 16.4 17.2 — 16.6 17.4 — 16.8 17.1 15.8 16.6 17.4

95

TC

— 180 201 — 183 202 — 187 208 — 191 210 175 193 212

SHC

— 103 74 — 109 78 — 119 84 — 129 89 175 138 95

kW

— 16.8 17.8 — 16.9 17.4 — 17.1 17.8 — 17.3 18.0 16.9 17.4 17.8

105

TC

— 169 186 — 171 190 — 175 193 161 177 197 164 180 200

SHC

— 94 65 — 100 68 — 109 74 155 119 80 164 127 85

kW

— 18.1 18.5 — 18.2 18.7 — 18.3 19.0 17.8 18.3 19.0 17.9 18.5 19.4

115

TC

— 156 174 — 159 176 — 163 179 149 165 182 153 166 185

SHC

— 84 55 — 90 58 — 99 63 146 108 69 152 117 74

kW

— 19.1 19.6 — 19.2 19.8 — 19.5 20.0 18.9 19.7 20.1 19.1 19.6 20.2

117

TC

— 154 171 — 156 174 — 159 177 146 162 179 150 163 181

SHC

— 82 53 — 88 56 — 97 61 143 106 66 150 115 71

kW

— 19.3 20.0 — 19.4 20.1 — 19.6 20.3 19.2 19.7 20.4 19.4 19.9 20.5

120

TC

— 150 ——152 ——155 — 143 157 — 146 159 —

SHC

— 79 —— 84 —— 94 — 140 102 — 146 111 —

kW

— 19.7 ——19.8 ——19.9 — 19.6 20.0 — 19.7 20.1 —

125

TC

———————————————

SHC

———————————————

kW

———————————————

BF —

Bypass Factor

Edb —

Entering Dry-Bulb

Ewb —

Entering Wet-Bulb

kW —

Compressor Motor Power Input

ldb —

Leaving Dry-Bulb

lwb —

Leaving Wet-Bulb

SHC —

Sensible Heat Capacity (1000 Btuh) Gross

TC —

Total Capacity (1000 Btuh) Gross

t

ldb

=t

edb

–

sensible capacity (Btuh)

1.10 x cfm

t

lwb

=

Wet-bulb temperature corresponding to enthalpy of air

leaving evaporator coil (h

lwb

)

h

lwb

=h

ewb

–

total capacity (Btuh)

4.5 x cfm

BYPASS FACTOR

(BF)

ENTERING AIR DRY-BULB TEMP (F)

79 78 77 76 75 under 75

81 82 83 84 85 over 85

Correction Factor

.05

1.04 2.07 3.11 4.14 5.18

Use formula

shown below.

.10

.98 1.96 2.94 3.92 4.90

.20

.87 1.74 2.62 3.49 4.36

.30

.76 1.53 2.29 3.05 3.82

0TFQ004-012

559F180-300