—

3

—

II. STEP 2 — FIELD FABRICATE DUCTWORK

On vertical discharge units, secure all ducts to roof curb and

building structure. Do not connect ductwork to unit. For hori-

zontal applications, field-supplied flanges should be attached

to horizontal discharge openings and all ductwork attached

to the flanges. Insulate and weatherproof all external duct-

work, joints, and roof openings with counter flashing and

mastic in accordance with applicable codes.

Ducts passing through an unconditioned space must be insu-

lated and covered with a vapor barrier.

If a plenum return is used on a vertical unit, the return

should be ducted through the roof deck to comply with ap-

plicable fire codes.

A minimum clearance to combustibles is not required around

ductwork on vertical discharge units. On horizontal discharge

units with electric heat, a minimum clearance of 1 in. is

required for the first 12 in. of ductwork. Cabinet return-air

static should not exceed –0.35 in. wg with Durablade econo-

mizer, –0.30 in. wg with EconoMi$er, or –0.45 in. wg without

economizer.

III. STEP 3 — INSTALL CONDENSATE DRAIN LINE AND

EXTERNAL TRAP

Condensate drain connections are located on the bottom and

end of the unit. Unit discharge connections do not determine

the use of drain connections; either drain connection can be

used in vertical or horizontal applications.

When using the standard end drain connection, make sure

the plug (Red) in the alternate bottom connection is tight

before installing the unit.

To use the bottom drain connection for a roof curb installa-

tion, relocate the factory-installed plug (Red) from the bot-

tom connection to the end connection. See Fig. 3. The piping

for the condensate drain and external trap can be completed

after the unit is in place.

All units must have an external trap for condensate drain-

age. Install a trap at least 4-in. deep and protect against

freeze-up. See Fig. 4. If drain line is installed downstream

from the external trap, pitch the line away from the unit at

1 in. per 10 ft of run. Do not use a pipe size smaller than the

unit connection (

3

/

4

in.).

IV. STEP 4 — RIG AND PLACE UNIT

Inspect unit for transportation damage. File any claim with

transportation agency. Keep unit upright and do not drop.

Spreader bars are not required if top crating is left on unit.

Rollers may be used to move unit across a roof. Level by

using unit frame as a reference. See Table 1 and Fig. 5 for

additional information. Operating weight is shown in

Table 1 and Fig. 5.

Lifting holes are provided in base rails as shown in Fig. 5

and 6. Refer to rigging instructions on unit.

Positioning

Maintain clearance around and above unit to provide proper

airflow and service access. See Fig. 6.

Position unit on roof curb so that the following clearances are

maintained:

1

/

4

-in. clearance between roof curb and base rails

on each side and in duct end of unit; 3

5

/

16

-in. clearance between

roof curb and condenser end (see Fig. 1, section C-C).

Do not install unit in an indoor location. Do not locate unit

air inlet near exhaust vents or other sources of contami-

nated air.

Although unit is weatherproof, guard against water from

higher level runoff and overhangs.

After unit is in position, remove polyethylene shipping wrap-

per and rigging skid.

CAUTION: Ensure voltage listed on unit data

plate agrees with electrical supply provided for the

unit.

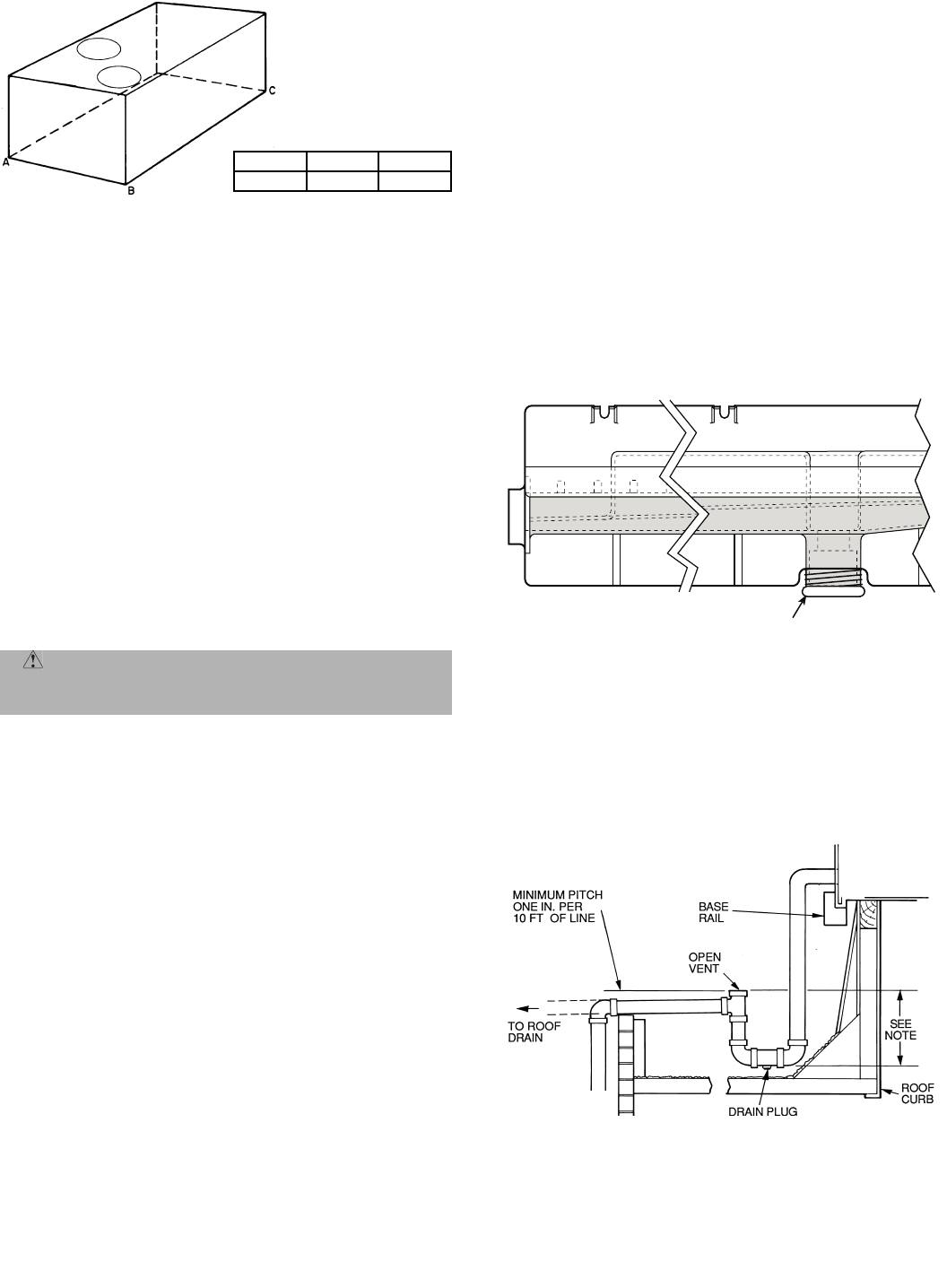

MAXIMUM ALLOWABLE

DIFFERENCE (in.)

A-B B-C A-C

0.5 1.0 1.0

Fig. 2 — Unit Leveling Tolerances

DRAIN PLUG

NOTE:

Drain plug is shown in factory-installed position.

Fig. 3 — Condensate Drain Connection

NOTE:

Trap should be deep enough to offset maximum unit static dif-

ference. A 4-in. trap is recommended.

Fig. 4 — External Trap Condensate Drain