—

11

—

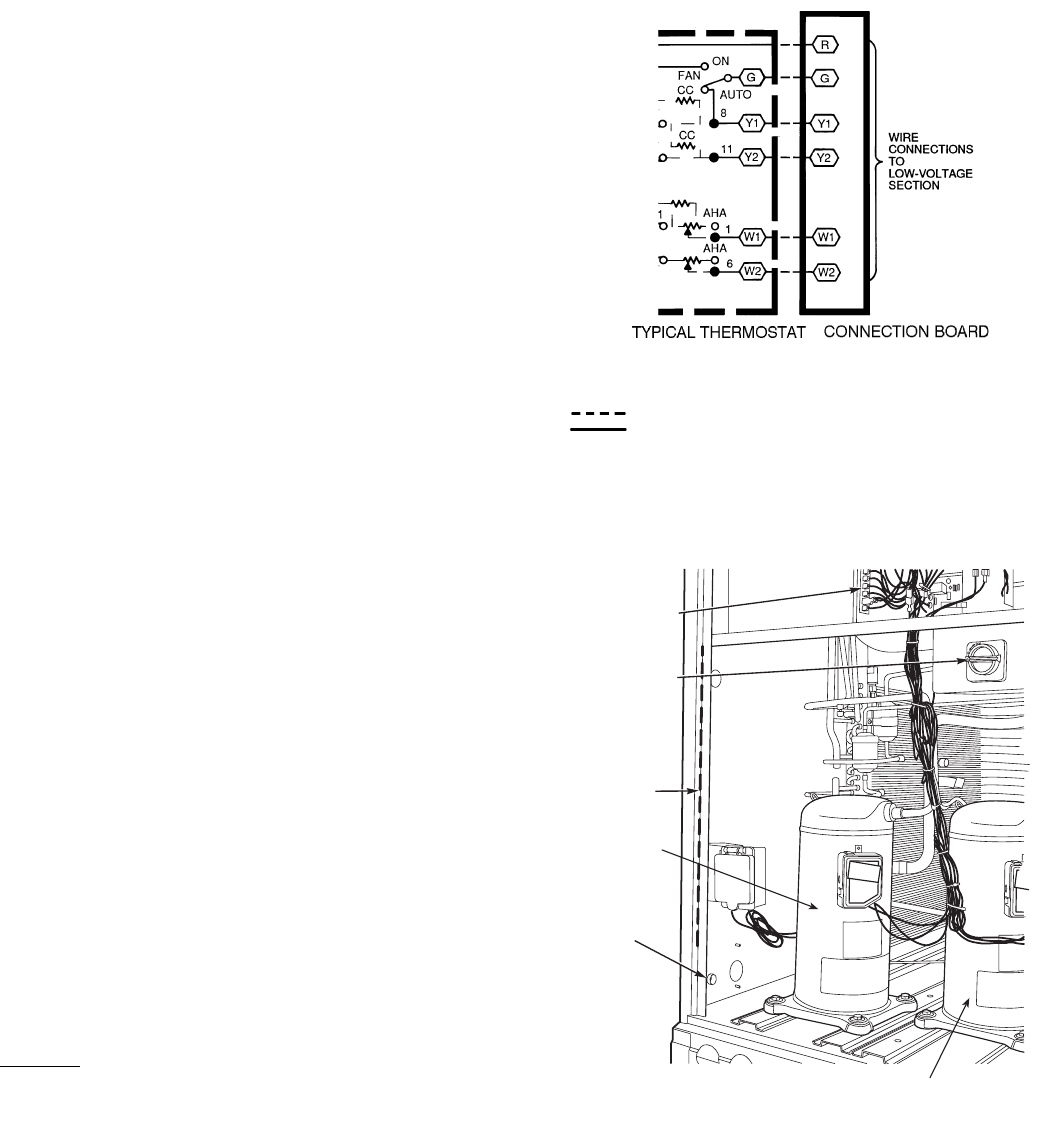

B. Field Control Wiring

Install an approved accessory thermostat assembly accord-

ing to installation instructions included with the accessory.

Locate thermostat assembly on a solid wall in the condi-

tioned space to sense average temperature in accordance

with thermostat installation instructions.

Route thermostat cable or equivalent single leads of colored

wire from subbase terminals to low-voltage connections on

unit (shown in Fig. 8) as described in Steps 1 through 4

below.

NOTE: If using Bryant electronic thermostat, set thermostat

configuration for “non-heat pump operation.” The use of the

O terminal is not required to energize the reversing valve in

this family of products.

NOTE: For wire runs up to 50 ft, use no. 18 AWG (American

Wire Gage) insulated wire (35 C minimum). For 51 to 75 ft,

use no. 16 AWG insulated wire (35 C minimum). For over

75 ft, use no. 14 AWG insulated wire (35 C minimum). All

wire larger than no. 18 AWG cannot be directly connected to

the thermostat and will require a junction box and splice at

the thermostat.

1. If unit is mounted on roof curb and accessory thru-

the-curb service plate connection is used, route wire

through connection plate.

2. Pass control wires through the hole provided on unit

(see connection D in Connection Sizes table in Fig. 6).

3. Feed wire through the raceway built into the corner

post to the 24-v barrier located on the left side of the

control box. See Fig. 9. The raceway provides the UL

required clearance between the high- and low-voltage

wiring.

4. Connect thermostat wires to screw terminals of low-

voltage connector (see Fig. 8).

NOTE: If thru-the-bottom power connections are used refer

to the accessory installation instructions for information on

power wiring. Refer to Fig. 6 for drilling holes in basepan.

C. Defrost Board

The defrost board timer cycle is set to 30 minutes. To change

the cycle time, remove the wire from defrost board connected

to the 30-minute quick-connect. See Fig. 10. Connect the

wire to the 50 or 90 minute quick-connects on the defrost

board, depending on the desired defrost time.

D. Heat Anticipator Settings

For units with electric heat, set heat anticipator settings as

shown in Table 3.

VI. STEP 6 — ADJUST FACTORY-INSTALLED OPTIONS

A. Disconnect Switch

The optional disconnect switch is non-fused. The switch has

the capability of being locked in place for safety purposes.

(See Fig. 9.)

B. Optional Durablade Economizer

The optional economizer hood assembly is packaged and

shipped in the filter section. Damper blades and control

boards are installed at the factory and the economizer is

shipped in the vertical discharge position.

NOTE: Horizontal discharge block-off plate is shipped with

the air hood package. If unit is to be used for vertical dis-

charge application, discard this plate.

Assembly

1. Determine if ventilation air is required in building. If

so, determine the minimum amount to be supplied by

each unit and record quantity of ventilation air

needed for use in Step 8.

2. Remove filter access panel by raising panel and

swinging panel outward. Panel is now disengaged

from track and can be removed. No tools are required

to remove filter access panel. Remove outdoor-air

opening panel. Save panels and screws. See Fig. 11.

Remove optional outdoor-air damper hood package

from filter section.

3. Assemble outdoor-air hood top and side plates as

shown in Fig. 12. Install seal strips on hoop top and

sides. Put aside screen retainer and retainer screw

for later assembly. Do not attach hood to unit at this

time.

COMPRESSOR

NO. 2

DISCONNECT

BOARD

DISCONNECT

SWITCH

(OPTIONAL)

RACEWAY

HOLE IN

END

PANEL

COMPRESSOR NO. 1

LEGEND

Fig. 8 — Low-Voltage Connections

AHA —

Adjustable Heat Anticipator

CC —

Cooling Compensator

Field Wiring

Factory Wiring

Fig. 9 — Typical Field Control Wiring Raceway