—23—

IX. COIL CLEANING AND MAINTENANCE

This section discusses the cleaning and the maintenance of

standard coils and E-Coated coils. Routine cleaning of coil

surfaces is essential to minimize contamination build-up and

remove harmful residue. Inspect coils monthly and clean as

required.

A. Cleaning Standard Coils

Standard coils can be cleaned with a vacuum cleaner,

washed out with low velocity water, blown out with com-

pressed air, or brushed (do not use wire brush). Fan motors

are dripproof but not waterproof. Do not use acid cleaners.

Clean coil annually or as required by location or outdoor air

conditions. Inspect coil monthly and clean as required. Fins

are not continuous through coil sections. Dirt and debris may

pass through first section and become trapped, restricting

airflow. Use a flashlight to determine if dirt or debris has col-

lected between coil sections.

Clean coils as follows:

1. Turn off unit power.

2. Remove screws holding rear corner posts and top

cover in place. Pivot top cover up 12 to 18 in. and

support with a board or other adequate rigid support.

See Fig. 24.

3. Remove clips securing tube sheets together at the

return bend end of the coil. Carefully spread the ends

of the coil rows apart by moving the outer sections.

See Fig. 25.

4. Using a water hose or other suitable equipment, flush

down between the sections of coil to remove dirt and

debris.

5. Clean the remaining surfaces in the normal manner.

6. Reposition outer coil sections. Reinstall clips which

secure tube sheets, and replace top cover and rear

corner posts.

7. Restore unit power.

B. Cleaning and Maintaining E-Coated Coils

Routine cleaning of coil surfaces is essential to maintain

proper operation of the unit. Elimination of contamination

and removal of harmful residue will greatly increase the life

of the coil and extend the life of the unit. The following

maintenance and cleaning procedures are recommended as

part of the routine maintenance activities to extend the life

of the coil.

Remove Surface Loaded Fibers

Debris such as dirt and fibers on the surface of the coil

should be removed with a vacuum cleaner. If a vacuum

cleaner is not available, a soft brush may be used. The clean-

ing tool should be applied in the direction of the fins. Coil

surfaces can be easily damaged (fin edges bent over) if the

tool is applied across the fins.

NOTE: Use of a water stream, such as a garden hose, against

a surface loaded coil will drive the fibers and dirt into the

coil. This will make cleaning efforts more difficult. Surface

debris must be completely removed prior to using low veloc-

ity clean water rinse.

Periodic Clean Water Rinse

A periodic clean water rinse is very beneficial for coils that

are applied in coastal or industrial environments. However,

it is very important that the water rinse is made with very

low velocity water stream to avoid damaging the fin edges.

Monthly cleaning is recommended.

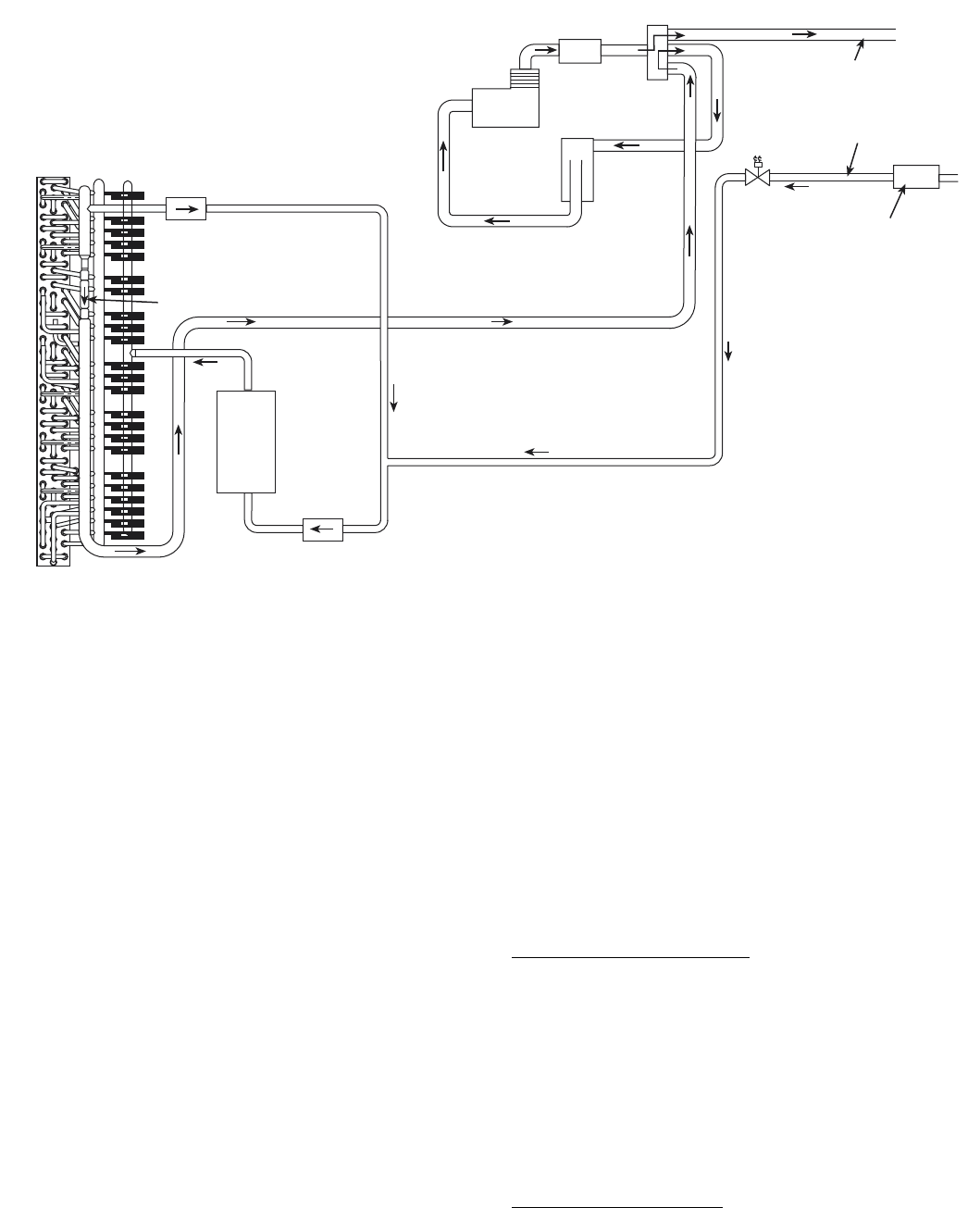

FILTER

DRIER

COMPR

CK VALVE B

CK VALVE A

CK VALVE C

LLSV

LIQUID

HOT GAS

GAS AND OIL

MUFFLER

ACCUMULATOR

REVERSING

VALVE

REFRIGERANT MIXTURE

FROM INDOOR

COIL

TO INDOOR

COIL

ANGLE

VALVE

WITH SCHRADER

PORT

COIL RETURN

BEND END

Fig. 23 — 541A180 Heating Mode