6. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

BAS-311H

41

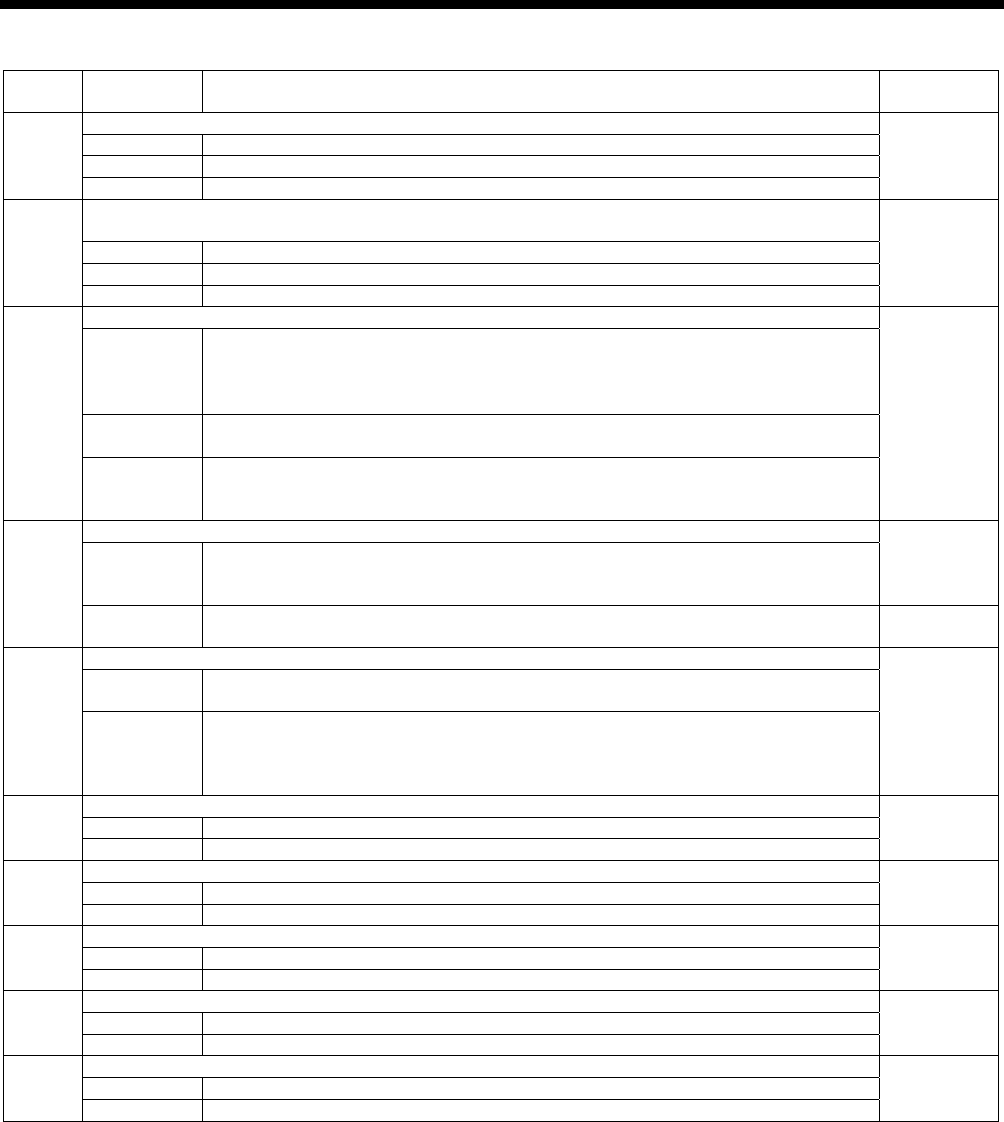

6-2. List of memory switch settings

No.

Setting

range

Setting items Initial value

Work clamp lift timing after sewing is completed

0 Work clamp is not raised automatically.

1 Work clamp is raised at the final stitch position.

001

2 Work clamp is raised after moving to the home position.

2

Work clamp lowering sequence for separate work clamp (pneumatic work clamp specifications

only)

0 Left and right work clamps are lowered at the same time.

1 Work clamp is lowered in the order left -> right.

002

2 Work clamp is lowered in the order right -> left.

0

Work clamp lowering operation (Motor-driven work clamp specifications only)

0

Analog lowering: Work clamp is lowered in direct proportion to the pedal

depression amount, and sewing starts when the pedal is fully depressed.

*This operation is only possible for foot switch specifications; for two-pedal foot

switch specifications, operation is the same as for a 2-step work clamp.

1

1-step work clamp: Work clamp is lowered when pedal is depressed to the 1st

step, and sewing starts when pedal is depressed to the 2nd step.

003

2

2-step work clamp: Work clamp is lowered to intermediate height when pedal is

depressed to the 1st step, and work clamp is fully lowered and sewing starts when

the pedal is depressed to the 2nd step.

2

Slow start method

OFF

The sewing speed for the first 5 stitches will be in accordance with the setting for

memory switch Nos. 151 to 155. (Ask the place of purchase for details on memory

switch Nos. 151 to 155.)

OFF

100

ON

The sewing speed for the first 5 stitches can be selected from the nine slow start

patterns “Lo1” to “Lo9”. (Refer to “5-2-1. Parameter list”.)

Lo4

Single-stitch test feed

OFF

Test feed starts when the foot switch (start switch) is depressed, and it continues

automatically until the final stitch.

200

ON

Test feed starts when the foot switch (start switch) is depressed, and it moves

forward by one stitch each time the switch is depressed. In addition, when the

TEST indicator is flashing, test feed will move forward one stitch at a time when

the machine pulley is turned by hand.

OFF

Production counter display

OFF Lower thread counter display

300

ON Production counter display

OFF

Sewing condition detail settings

OFF Parameters which are common to all programs are used.

400

ON Parameters can be set separately for each program.

OFF

Unit display for pattern zoom ratio

OFF Displayed as %.

402

ON Displayed as mm.

OFF

Split mode selection

0 Continuous split mode

403

1 Single split mode

0

Cycle program No. (C01 to C30) display

OFF Disabled (not displayed)

405

ON Enabled (displayed)

ON