7

AquaSmart Boiler Control Manual

Compare the attached wires to available wiring

diagrams on the control cover and to the devices to

which they can be traced. If wiring diagrams have

been lost they are available later in this manual.

Label each wire accordingly, to ensure accurate

reconnection. (Masking tape works well for labeling.)

Remove each wire from the old control. Make sure

each label is intact.

Loosen the control mounting arrangement and remove

the control from the system.

Make note of the temperature settings for high limit,

low limit and differentials. This will provide important

reference data for the new control adjustment. Please

note that differentials may be used differently in other

manufacturer’s controls. See Figure 19 & 16 toward

end of manual for a description of how the

AquaSmart’s differentials work. Consult the manual of

the control being replaced for information regarding its

differentials.

1.

2.

3.

4.

5.

Installing the Temperature Sensor

Figure 4a - Installation of Temperature Sensor in Immersion Well

This is very important for successful control operation.

Temperature Sensor

Brass Fitting

Sensor must butt against end

Copper Well Tube

Sensor connects to Beckett AquaSmart

Removing the Control to be Replaced

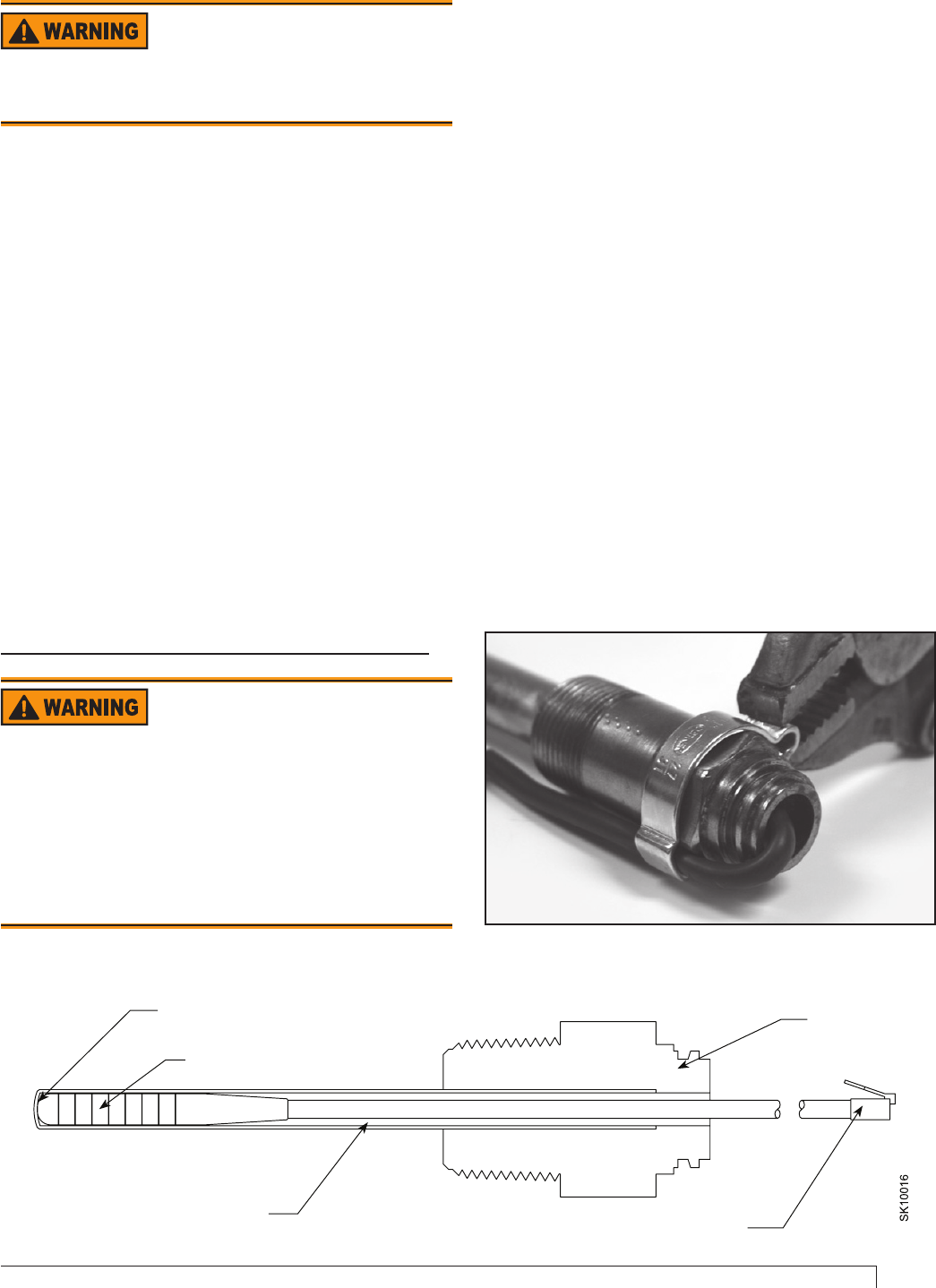

Figure 4b - Strain Relief

Electrical shock hazard.

Disconnect all electrical power to the appliance

circuit before replacing the control. There may be

more than one disconnect switch.

Burn and Scald Hazard

Excessive water temperatures could cause

explosion, burns, scalding, pressure relief fl ooding

and fi tting leaks.

Carefully follow the outlined procedures for temperature

sensor installation to ensure accurate water

temperature sensing and effective control operation.

Make sure the plumbing for domestic hot water has

anti-scald valve protection.

y

y

Make sure the immersion well is clean inside, has no

leaks, is of proper length and is otherwise suitable for

receiving the new control and temperature sensor.

Replace questionable wells with new ones and use

pipe sealant to seal the threads.

Grasp the sensor lead, just behind the sensor probe

and carefully insert it into the well until it comes to rest

at the very end of the well.

The sensor is designed

with radial splines to provide a snug fi t in most

standard wells.

The thermal time constant of the sensor is 40

seconds. Consider using thermal grease if faster

response in desired.

Surface mounting may require additional lead length

to reach the control receptacle. Use the extension

cable (part no. 52120), found in the 7600RMU Remote

Mount Kit, to extend the lead by 48”.

Install the strain relief (part no. 3266201) as shown,

capturing the cable against the hex. Crimp the

strain relief opposite side of the cable. This anchors

the sensor securely inside the immersion well.

Plug the temperature sensor lead terminal into the

receptacle on the control base. See Figure 10.

Note: The sensor is not tested and approved for being

mounted to the outside of a pipe. It is for use in immersion

wells only.

1.

2.

3.

4.

5.

6.

7.