18

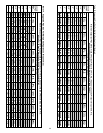

ONE GENESIS (MODEL GW) HOT WATER SUPPLY BOILER WITH HORIZONTAL TANK

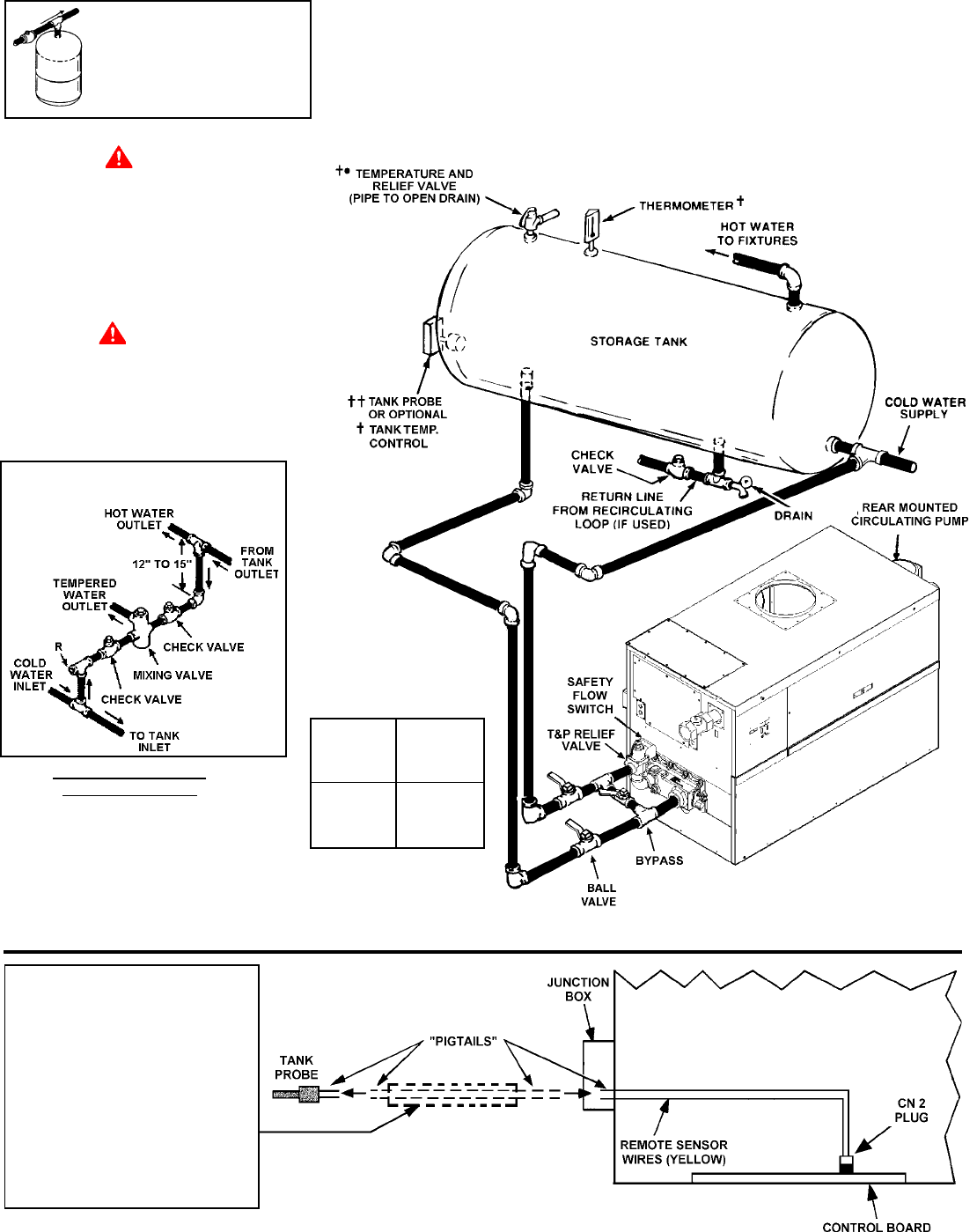

Figure 12. Tank probe installation.

PRESSURE RELIEF VALVE RATING SHOULD

NOT EXCEED PRESSURE CAPACITY OF ANY

COMPONENT IN THE SYSTEM.

PIPING SHOULD CONFORM TO LOCAL CODES.

BALL VALVES ARE SHOWN FOR SERVICING

BOILER. HOWEVER, LOCAL CODES SHALL

GOVERN THEIR USAGE.

DANGER

TEMPERATURE SETTING SHOULD NOT EXCEED

SAFE USE TEMPERATURE AT FIXTURES.

SEE WATER TEMPERATURE CONTROL

WARNING ON PAGE 23. IF HIGHER PREHEAT

TEMPERATURES ARE NECESSARY TO OBTAIN

ADEQUATE BOOSTER OUTPUT, ADD AN

ANTI-SCALD VALVE FOR HOT WATER

SUPPLIED TO FIXTURES.

WARNING

THE WATER MANIFOLD IS NOT DESIGNED TO

SUPPORT THE WEIGHT OF THE WATER PIPING

SYSTEM. AS ON ALL BOILER INSTALLATIONS,

SPECIAL CARE MUST BE TAKEN TO ENSURE

PROPER SUPPORT.

Figure 11. Single boiler with horizontal tank.

IMPORTANT

SAFETY FLOW SWITCH PROTECTS THE

BOILER IN CASE OF WATER SERVICE

INTERRUPTION OR CIRCULATOR FAILURE.

• PIPE TO OPEN DRAIN

X FACTORY-INSTALLED ON UNIT

SUPPLIED WITH UNIT

FIELD-INSTALLED

INSTALL THERMAL EXPANSION

TANK ON COLD WATER

SUPPLY LINE, IF CHECK VALVE

OR PRESSURE REDUCING

VALVE IS USED IN SUPPLY.

Encase field-supplied wires

between tank probe and junction

box with 1/2" field supplied

conduit. "Pigtails" of field-

supplied wires should be spliced

to "pigtails" of tank probe and

connected to 24 VAC junction box

(see figure 20). This conduit and

wiring should be separate from

any other conduit/wiring to guard

against EMI (electromagnetic

interference).

MINIMUM

PIPE SIZE

MODELS INCHES

GW-1000

THRU 2 1/2"

2500 NPT

FACTORY PUMP SIZING

BASED ON 50 EQUIVALENT

FEET (15.2 m) OF PIPE.

MODELS

CIRCULATING RETURN

LINE CONNECTIONS

• TEMPERED WATER LOOP, IF USED,

CONNECT TO POINT R.

• STORED TEMPERATURE WATER LOOP,

IF USED, CONNECT TO ANY OPENING

NEAR BOTTOM OF TANK.

TWO TEMPERATURE WATER

MIXING VALVE APPLICATION