23

CHANGING ROTATION

WARNING: Rotating Components

Hazard

Do not operate pump without all guards in place. Failure

to follow these instructions could result in serious

personal injury or death and property damage.

8200 Series centrifugal pumps can be

operated clockwise or counterclockwise when

viewed from the coupling end of the pump. If

you wish to reverse the suction and discharge

nozzles; i.e., change rotation, this can be

accomplished with the same pump as follows:

1. Remove the impeller from the shaft, and

relocate the two impellers per Figure 10 for the

desired rotation. (Follow the disassembly

procedures given in this manual.)

2. With the rotating element out of the

casing, remove the casing from the base

and turn 180°. (Factory bases are drilled

for both rotations.)

3. Set the rotating element back in the

casing and reassemble the pump.

NOTE: The impeller and casing are in the

same relationship to each other as they were

originally. The shaft and motor are also in the

same relationship to each other as they were

originally. The suction and discharge are

offset, so the piping will need to be changed

to accommodate the new flange locations.

4. Reassemble the pump and realign the

coupling as called for in the alignment

instructions.

5. The rotation of the motor must be

changed by switching the motor leads.

NOTE: Unless the motor rotation is reversed

the impeller will run backward.

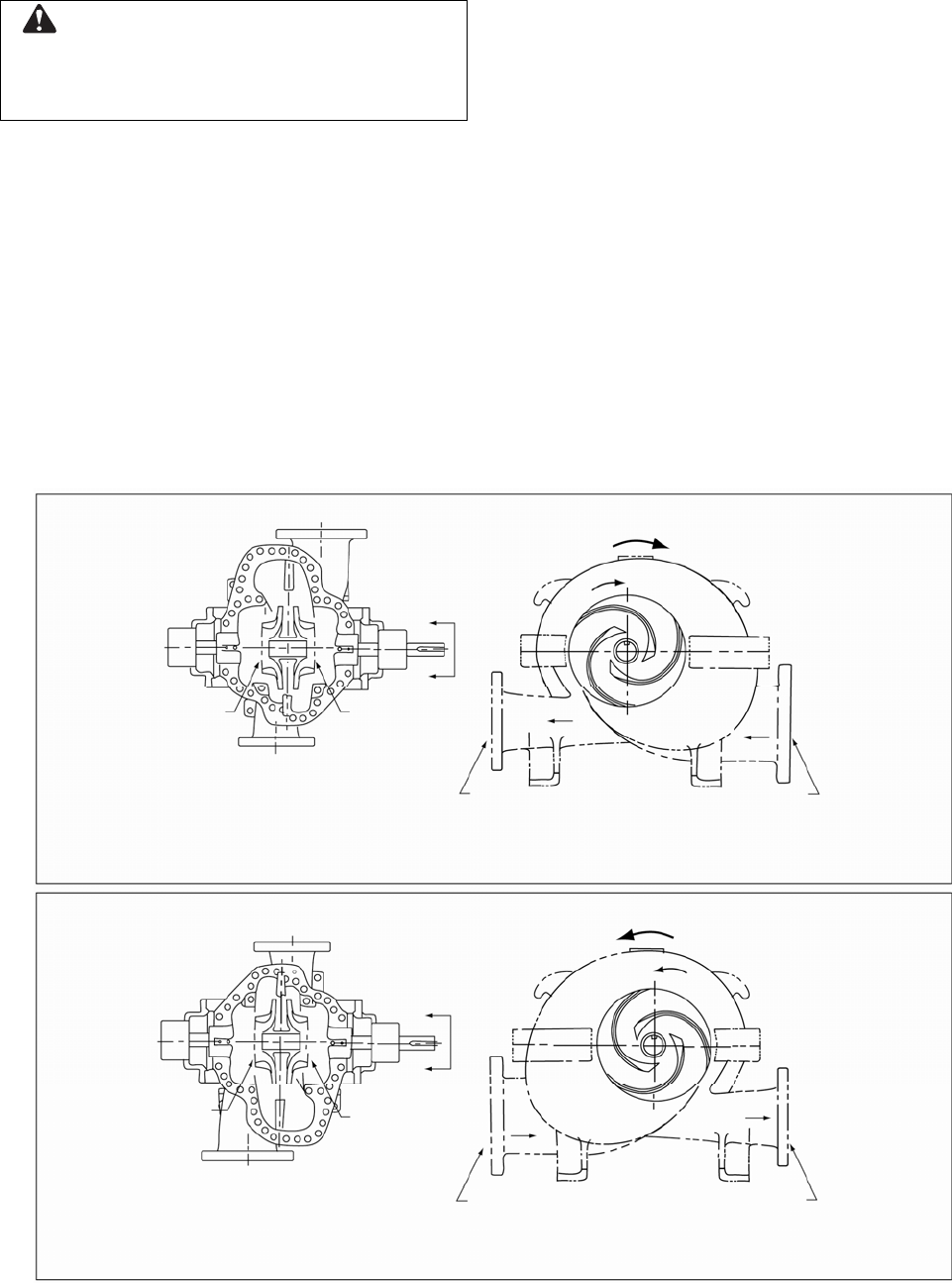

FIGURE 10 – CORRECT RELATIONSHIP OF THE IMPELLERS AND CASING

SUCTION

2ND STAGE

IMPELLER

DISCHARGE

1ST STAGE

IMPELLER

DISCHARGE

“A”

“A”

CW ROTATION

IMPELLER VANE

ORIENTATION “

A

-

A

”

SUCTION

CLOCKWISE ROTATION

VIEWED FROM THE COUPLING END

SUCTION

2ND STAGE

IMPELLER

DISCHARGE

1ST STAGE

IMPELLER

DISCHARGE

“A”

“A”

CCW ROTATION

IMPELLER VANE

ORIENT

A

TION “

A

-

A

”

SUCTION

COUNTERCLOCKWISE ROTATION

VIEWED FROM THE COUPLING END