23

Special Set-Up Procedure

WARNING – Turn off electrical power

and disconnect power cord from

electrical supply before beginning special

set-up procedure. If power cord is not

disconnected, severe injury to personnel

could result.

Changing Tape Leg Length

(From 70 to 48 mm [2-3/4 to 2 Inches])

The following changes to the case sealer will allow

taping boxes 90 mm [3-1/2 inches] minimum height.

CASE SEALER FRAME

1. No changes to case sealer frame are required.

WARNING – Use care when working

near tape cut-off knife as knife is

extremely sharp. If care is not taken,

severe injury to personnel could result.

TAPING HEADS

1. Lift the lower taping head straight up to remove

it from the case sealer bed.

2. Refer to Section

II

, Adjustments – Changing

Tape Leg Length", page 13 for taping head

set-up.

Drive Belt Assembly Height

The drive belt assemblies can be raised 48 mm

[2 inches] to provide better conveying of tall boxes.

This change increases the minimum box height

that can be taped to 190 mm [7-1/4 inches].

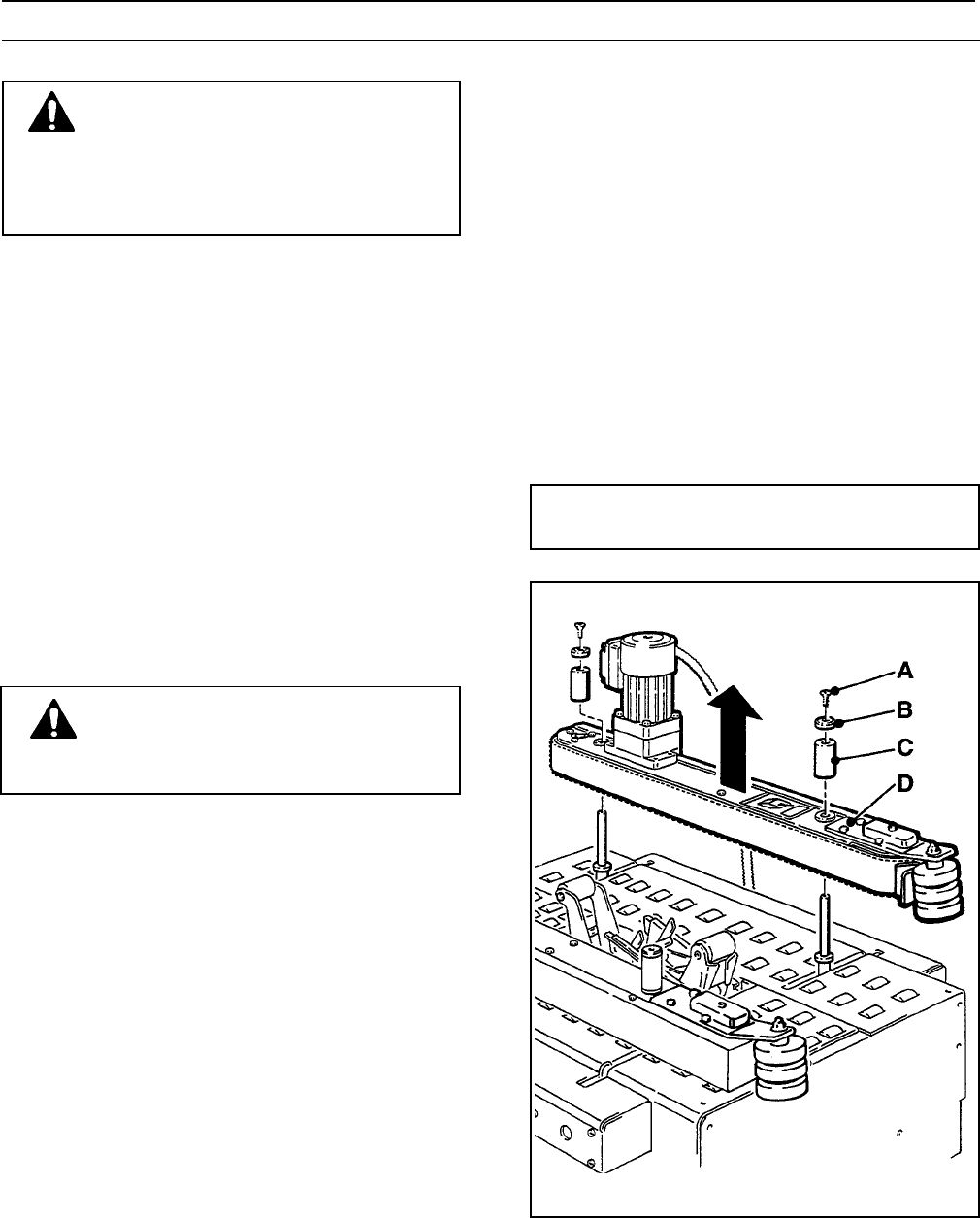

DISASSEMBLE – Figure 5-1

1. Remove and retain the screw (A), cap washer

(B) and spacer (C) from the front and rear arm

assembly pivots.

2. Lift belt drive assembly (D) up off the arm

assembly pivots.

Figure 5-1 – Drive Belt Assembly, Disassembly

Note – Keep motor in vertical position to

prevent gear oil from leaking out of motor.