3-speed direct-drive fan motor. The 6-ton unit has a single

speed direct-drive fan motor. Belt-drive blowers are also

available on all 3, 4, 5 and 6-ton models.

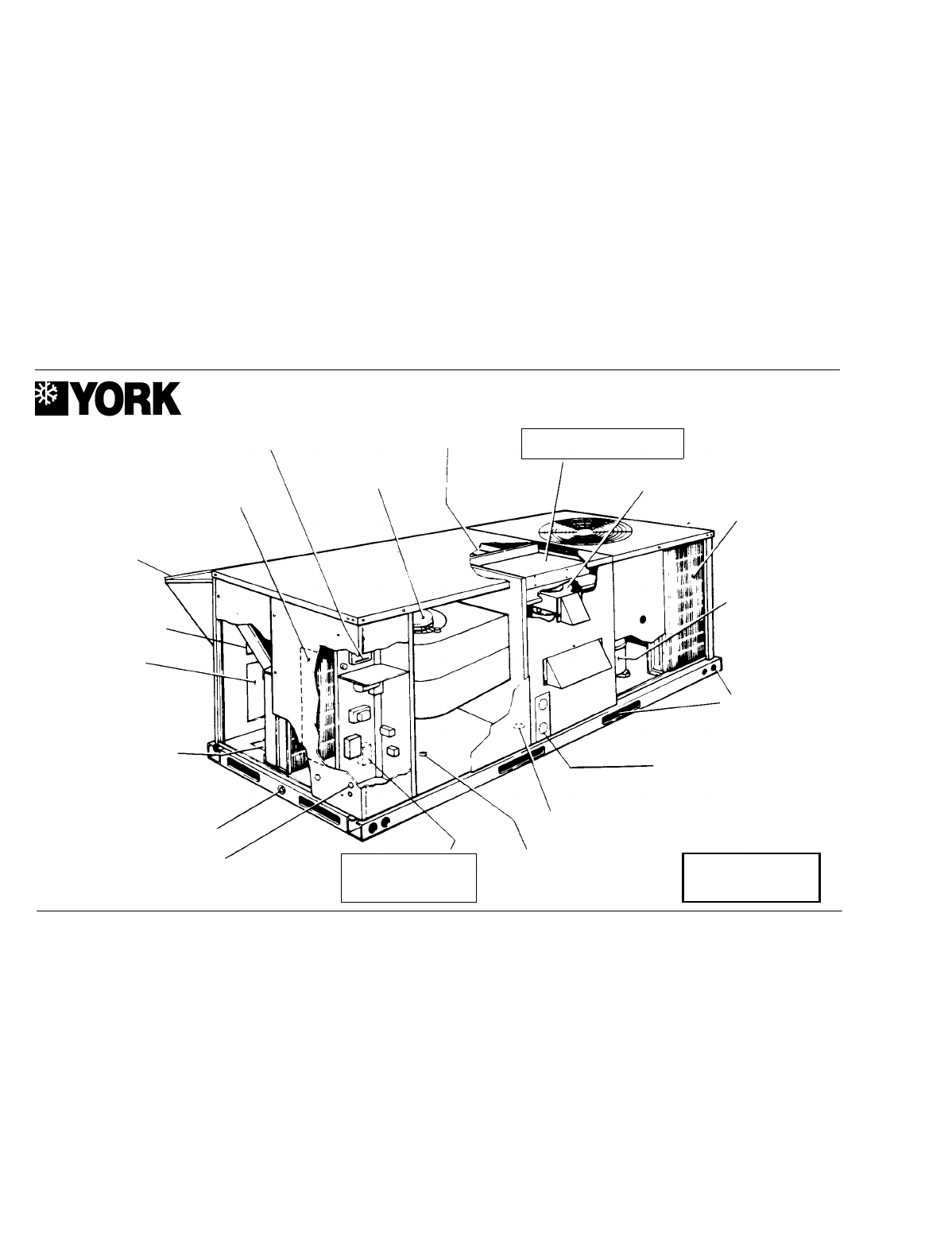

FULL PERIMETER BASE RAILS -

The permanently attached

base rails provide a solid foundation for the entire unit and

protect the unit during shipment. The rails provide fork lift

access from 3 sides, and rigging holes are also provided so

that an overhead crane can be used to place the units on a roof.

SYSTEM PROTECTION -

Internal overload protection are

standard on all scroll compressors. Every unit has a liquid line

filter-drier, high and low pressure/lose at charge switches and a

suction line freezestat to protect all system components. All units

will provide cooling at ambient temperatures down to 45°F.

UTILITY CONNECTIONS MADE EASY -

Gas and electric

utility knockouts are provided in the unit base as well as the

side of the unit. A clearly identified location is provided to mount

a field supplied electrical disconnect switch. Utility connections

can be made quickly and with a minimum amount of field labor.

SIMPLE CONTROL CIRCUIT -

A low voltage printed circuit

board contains a scroll compressor lockout indicator light and

a low voltage terminal strip. An additional set of pin connectors

is also provided to simplify the field interface of external

controls. Mate-n-lock plug connectors are used where line and

low voltage wires pass thru internal bulkheads. This allows for

easier troubleshooting and component replacement. The

electrical control box is not located in the scroll compressor

compartment so the access cover can be removed for

troubleshooting without affecting the normal system operating

pressures. All wiring internal to the unit is color/number coded.

AIR FILTERS -

Units are shipped with 1" disposable filters. The

unit filter racks can accommodate 1" or 2" filters without any

modifications.

TABLE OF CONTENTS

FEATURES

- CONT’D.

COPPER TUBE /

ALUMINUM FIN

CONDENSER COIL

20 GAUGE ALUMINIZED STEEL

TUBULAR HEAT EXCHANGER

DIRECT DRIVE

BLOWER MOTOR

(Belt Drive Option

also available on

some models)

LOW VOLTAGE RELAY BOARD

AND TERMINAL STRIP

OUTDOOR AIR OPENING

FOR SLIDE-IN/PLUG IN

INTERNAL ECONOMIZER

(ACCESSORY)

ELECTRICAL DISCONNECT

MOUNTING LOCATION

(Field Installed)

ECONOMIZER HOOD

SIDE RETURN AIR

DUCT OPENING

(Return Air & Supply Air

Side by Side)

BOTTOM RETURN AIR

DUCT OPENING

(Return Air & Supply Air

Side by Side)

3/4" PVC FEMALE

CONDENSATE DRAIN

KNOCKOUTS FOR SIDE

POWER AND CONTROL

ENTRY

KNOCKOUT FOR BOTTOM

GAS SUPPLY ENTRY

KNOCKOUT FOR BOTTOM

POWER ENTRY

KNOCKOUT FOR SIDE

GAS SUPPLY ENTRY

HIGH EFFICIENCY

SCROLL COMPRESSORS

BASE RAILS

WITH FORKLIFT SLOTS

AND LIFTING HOLES

POWER VENTER MOTOR

ELECTRIC HEAT ACCESSORY

LOCATION (Elec/Elec Units)

TERMINAL BLOCK

(For Single Point Power

Supply on Elec/Elec Units)

MODEL DCG

(Gas Heating)

Static Resistances..............................................................11

Motor and Drive Data .........................................................11

Electrical Data - Basic Units...............................................11

Elec. Data-Clg./Elec. Htg. 3 & 4 Ton w/Direct-Drive ...........12

Elec. Data-Clg./Elec. Htg. 5 & 6 w/Direct-Drive..................13

Elec. Data-Clg./Elec. Htg. 3 & 4 w/Belt-Drive .....................14

Elec. Data-Clg./Elec. Htg. 5 & 6 w/Belt-Drive .....................15

Field Wiring.........................................................................16

Unit Dimensions ........................................................ 17 & 18

Roof Curb Dimensions .......................................................19

Component Weights and Center of Gravity........................19

Typical Applications ............................................................20

Mechanical Specifications..................................................21

Description ...........................................................................1

Features ...............................................................................1

Ratings .................................................................................3

Sound Power Ratings for Supply Air Blower........................3

Physical Data........................................................................3

Cooling Capacities - 3 Ton ...................................................4

Cooling Capacities - 4 Ton ...................................................5

Cooling Capacities - 5 Ton ...................................................6

Cooling Capacities - 6 Ton ...................................................7

Blower Performance - 3 & 4 Ton w/Belt-Drive ......................8

Blower Performance - 5 & 6 Ton w/Belt-Drive ......................9

Blower Performance - 3 - 6 Ton w/Direct-Drive..................10

Option and Accessories .....................................................10

®

SUNLINE 2000

530.18-TG1Y

2 Unitary Products Group