15

IGNITION FUNCTIONAL CHECK 1

PILOT WILL NOT LIGHT

Ensure there is no debris around the pilot assembly,

(e.g. soot, etc.) which could short the spark, clean the area.

Operate the valve.

Is there a spark?

Consult Section

2 and retry.

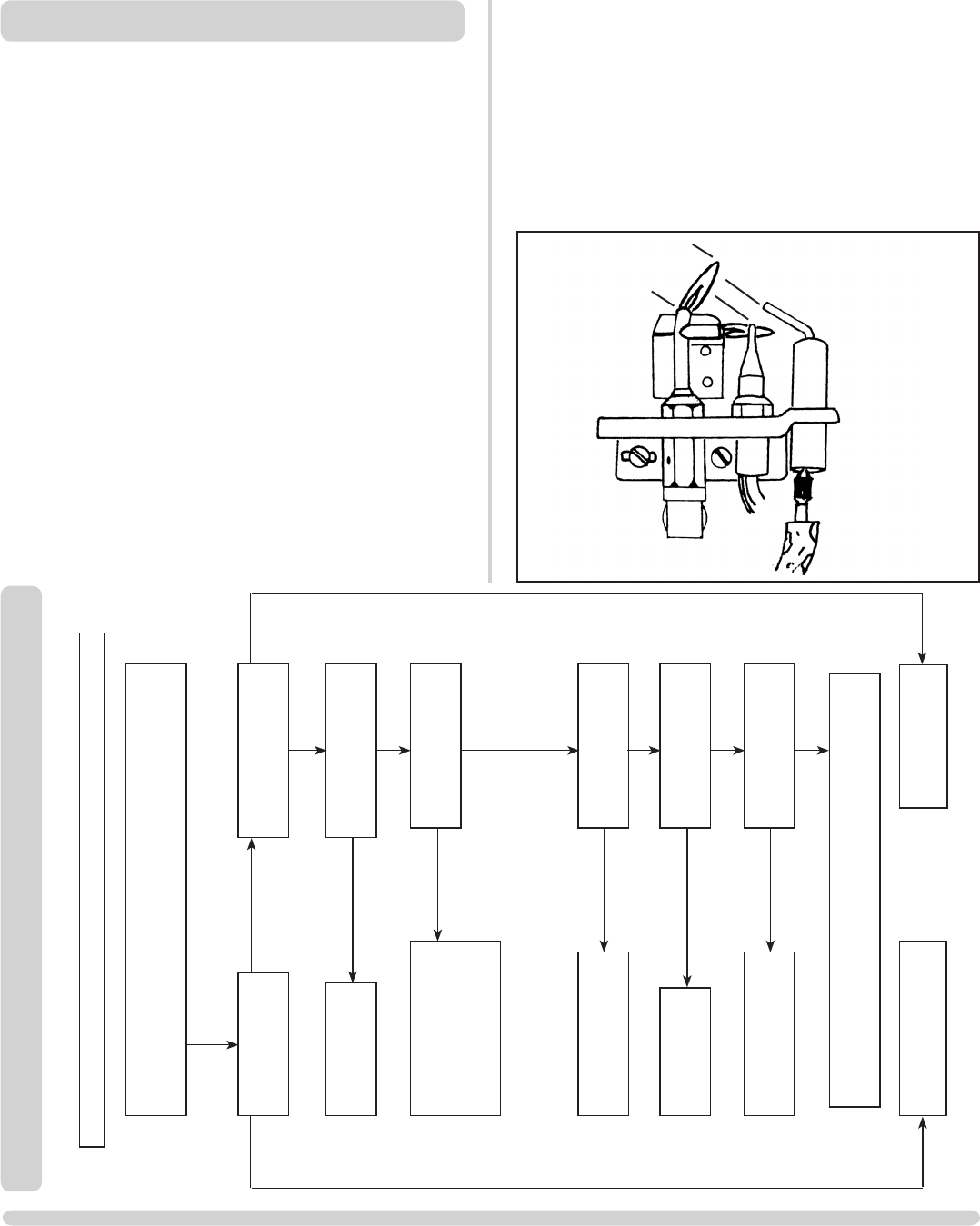

Check alignment of pilot

burner head, change the

ignition lead,

see Diagram 1 on page 14.

Check isolation tap and

gas meter, retry.

Correct and

retry.

Purge the gas pipes

and retry.

SEE 'NO SPARK'

CHART

SYSTEM OK

There is a blockage in the system, check the inlet test point,

the mag seating, valve and pilot filter.

Is the gas turned on to the

appliance?

Is the gas pressure correct?

Has the system got

any air in it?

Does the pilot light?

Is the control being

operated correctly?

Will the pilot light

with a match?

No Yes

No

Yes

No

Yes

Yes

No

No

Yes

No

No

Yes

Yes

SERVICING INSTRUCTIONS

SERVICING REQUIREMENTS/ FAULT FINDING CHARTS

1. SERVICING REQUIREMENTS

IMPORTANT – The glass panel on this appliance should

be checked for any signs of damage on the front face of

the glass panel (scratches, scores, cracks or other surface

defects). If damage is observed, the glass panel must be

replaced and the appliance must not be used until a

replacement is installed. Under no circumstances should

the appliance be used if any damage is observed. Please

isolate the appliance until a replacement glass panel has

been obtained and installed. Replacement glass panels

can be purchased from Gazco via the retailer from which

the appliance was purchased or any other Gazco

distributor.

This appliance must be serviced at least once a year by a

competent person. All tests must be serviced by best

practice as described by the current Gas Safe

recommendations.

1.1 Before any test are undertaken on the appliance, conduct a

gas soundness test for the property to ensure that there are

no gas leaks prior to starting work.

1.2 Before any tests are undertaken on the appliance it is also

recommended to fully check the operation of the appliance.

1.3 Special checks:

—Clean any lint or fluff from the pilot - pay particular

attention to the aeration hole in the side of the pilot.

—Clean away any fluff or lint from under the burner.

—Check that the spark gap on the pilot is correct.

1.4 Correct any faults found during the initial tests and then

re-commission the appliance conducting the usual safety

checks.

1.5 Advise the customer of any remedial action taken.

AR0097

3.5mm

15mm