GOLD

CGi-4E Gas-Fired Water Boiler — Boiler Manual

14

Part Number 550-110-711/1108

Venting — general information3a

CGi-4E venting methods — Chimney draft or Direct exhaust

Chimney draft venting

Chimneydraftventingusesthenaturaldraftprovidedbyaver-

ticalventorchimney.CategoryIappliance(non-positivevent

static pressure and vent gas temperature that avoids excessive

condensateproductioninvent).SeeSection3b.Chimneydraft

installations use:

1. Ventconnector(singleordoublewall)sizedtoeliminateposi-

tivepressureinventsystem.Diameterincreasesimmediately

at boiler.

2. Doublewallmetalvent(B-vent)orchimneywithlinerap-

provedbytheNationalFuelGasCode,ANSIZ223.1–latest

edition,orinCanadaB149.1orB149.2InstallationCode.

Direct exhaust — vertical or sidewall

Directexhaustventingusesinsidecombustionairwithnocom-

bustionairconnectorpiping.TheCGi-4Euegasventispressur-

ized,requiringcarefulsealingofalljoints.CategoryIIIappliance

(positive vent static pressure and vent gas temperature that avoids

excessivecondensateproductioninvent).Seepages15-19.

Directexhaustinstallationsuse:

1. Ventpipespeciedinthismanual.

2. Ventterminationthroughoutsidewall,rooforunusedchim-

ney. Tight chimney areas will make vent joint construction

very difficult.

Venting — chimney draft venting3b

1. Usedoublewallmetalvent(B-vent)orchimneywithlineras

requiredbytheNationalFuelGasCode,ANSIZ223.1–latest

edition,orinCanada,B149.1orB149.2InstallationCode.

2. To prevent downdrafts, chimney should extend at least 3 feet

above the highest point where it passes through a roof and

at least 2 feet higher than any portion of a building within

a horizontal distance of 10 feet.

3. Toventwithanotherappliance,seeNationalFuelGasCode,

ANSIZ223.1–latesteditionorinCanadaB149.2orB149.2

InstallationCode

4. Donotconnectbreechingtoanyportionofamechanical

draft system that can operate under positive pressure.

5. Maintainminimum2”clearancefromcombustiblematerials

to vent pipe.

6. Donotusechimneywithanopenreplace.

7. Make horizontal runs as short as possible. Long runs can

cause condensation.

8. When longer runs are used, support pipe with appropriate

hangers.

9. To prevent blockage, do not vent into bottom of chimney.

10.Ventpipemustnotgobeyondinsidewallofchimney.

11.Ventpassingthroughfloorsorceilingsmustbefire-

stopped.

12.See

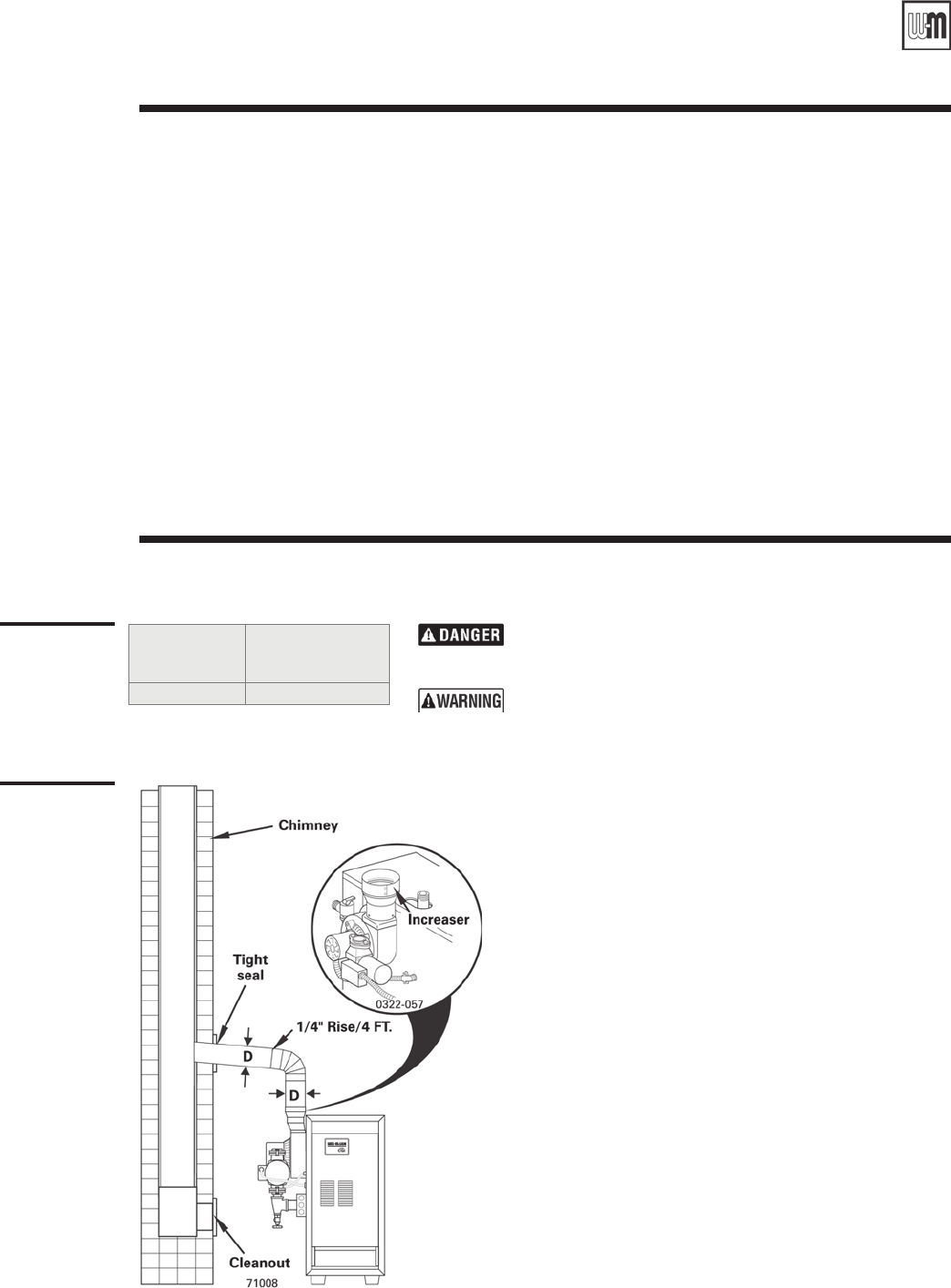

Figure 7 and Table 3 to connect boiler to venting sys-

tem.

Inspect existing chimney before installing boiler. Failure to

clean or replace perforated pipe or lining will cause severe

personal injury or death.

Table 3

Vent

connector

diameter

VentsizinggiveninTable 3 is only a general guideline. The

vent connector and chimney must be designed, sized and

constructed in compliance with all applicable codes. Failure to

correctly size and install the vent system could result in severe

personal injury, death or substantial property damage.

Figure 7

Chimnney

draft

venting

Boiler

model

number

“D” Minimum

vent connector

diameter

CGi-4E 5”