LX and LT Pool Heaters

Page 15

Table 6. Chemical Concentration Levels

Test Recommended Level*

Free Chlorine or 1.0 to 3.0 ppm

Total Bromine 2.0 to 4.0 ppm

pH 7.2 to 7.6

Total Alkalinity (TA) 100 to 150 ppm

Calcium Hardness (CH) 200 to 400 ppm

Langelier Saturation Index (SI) -0.5 to +0.5

Cyanuric Acid 30 to 150 ppm

Total Dissolved Solids (TDS) Less than 1500 ppm

Copper 0 ppm

*As recommended by IPSA

2J. Start-up and Adjustment

2J-1. Normal Operation

The LX and LT heaters are capable of automatic

operation based on a call for heat at preset temperatures

and an operator selection between pool or spa settings.

Additionally, the heater may be controlled by a remote unit

to anticipate bather load, changes in temperature settings,

or a variety of other demands that might be encountered.

The heater has an internal safety system which allows

operation in a variety of conditions and prevents operation

when certain adverse conditions are encountered. The

heater is capable of diagnosing problems within the safety

controls scheme, enabling faster service and less down

time in the event of a failure.

When the heater is powered, water is flowing

through the heater, and the water temperature entering the

heater is below the temprature control setting, the heater is

ready to ignite. The combustion fan is powered and if

airflow is proved adequate the igniter comes on 45 seconds

into the call for heat. At 60 seconds into the call for heat,

the gas valve opens and gas flows to the burners.

If ignition is unsuccessful, or if the flame fails

during normal operation, the ignition control shuts off the

gas valve. It imposes a post purge and two more ignition

cycles, and it shuts down the system if ignition is not

achieved in three cycles.

To reset the model LX for another three cycles, press

and release the mode button until the indicator on the LCD

screen aligns with "OFF". Now press and release the

button again until the indicator on the LCD screen aligns

with the desired setting, either "POOL" or "SPA".

To reset the model LT press and release the mode

button until the indicator lights for the "SPA" and "POOL"

settings are off. Then press and release it again until the

indicator light for the desired setting is back on.

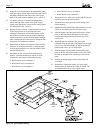

13. Reinstall the adapter, with the PRV, into the plastic

threaded hole and tighten it until the mark on the

adapter is once again facing the same direction as the

water connections on the header.

Do not use any pipe compound or pipe dope

on the threads of the adapter or any part that

comes in contact with the plastic headers.

These compounds may damage the header

over a period of time.

DO NOT TIGHTEN WITH A WRENCH.

Overtightening may crack the header. Route the discharge

piping so that steam from the pipe does not endanger

anyone near the heater. Refer to your local installation

codes for more detailed information. The valve setting

should be at or below the maximum working pressure of

any component in the filter system. The working pressure

of the LX heater is 75 psig.

2I-5. Automatic Chlorinators

(Chemical Feeders)

A high concentration of chlorine (and many similar

chemicals) in the pool heater can be very destructive.

Heater damage caused by chemical concentration is not

covered by the Waterpik Technologies Warranty. See

Table 6 for guidelines on pool water chemistry.

IMPORTANT: If an automatic chlorinator is

being used, equip the chlorinator with an anti-

siphoning device so that chlorine will not siphon into

the heater after the pump shuts off.

Wire an electric chlorinator so that it cannot operate

unless the filter pump is running. If the chlorinator has an

independent clock control, synchronize it with the filter

clock.

Always install a chlorinator so that it introduces the

chlorine downstream from the heater, and, if possible,

below the level of the heater outlet fitting.

CAUTION