Page 8

12. Before operating the heater, test the complete gas

supply system and all connections for leaks using a

soap solution. Do not use an open flame.

CAUTION

Some leak test solutions (including soap and

water) may cause corrosion or stress cracking.

Rinse the piping with water after testing.

2G-2. Special Precautions for

Propane Gas

Liquefied petroleum (LP) gas is heavier than air.

Therefore, do not install pool heaters using LP gas in pits

or locations where gas might collect. Locate heaters a safe

distance from LP gas storage and filling equipment.

Consult local codes and fire protection authorities about

specific installation restrictions.

2H. Electrical Power

2H-1.General Information

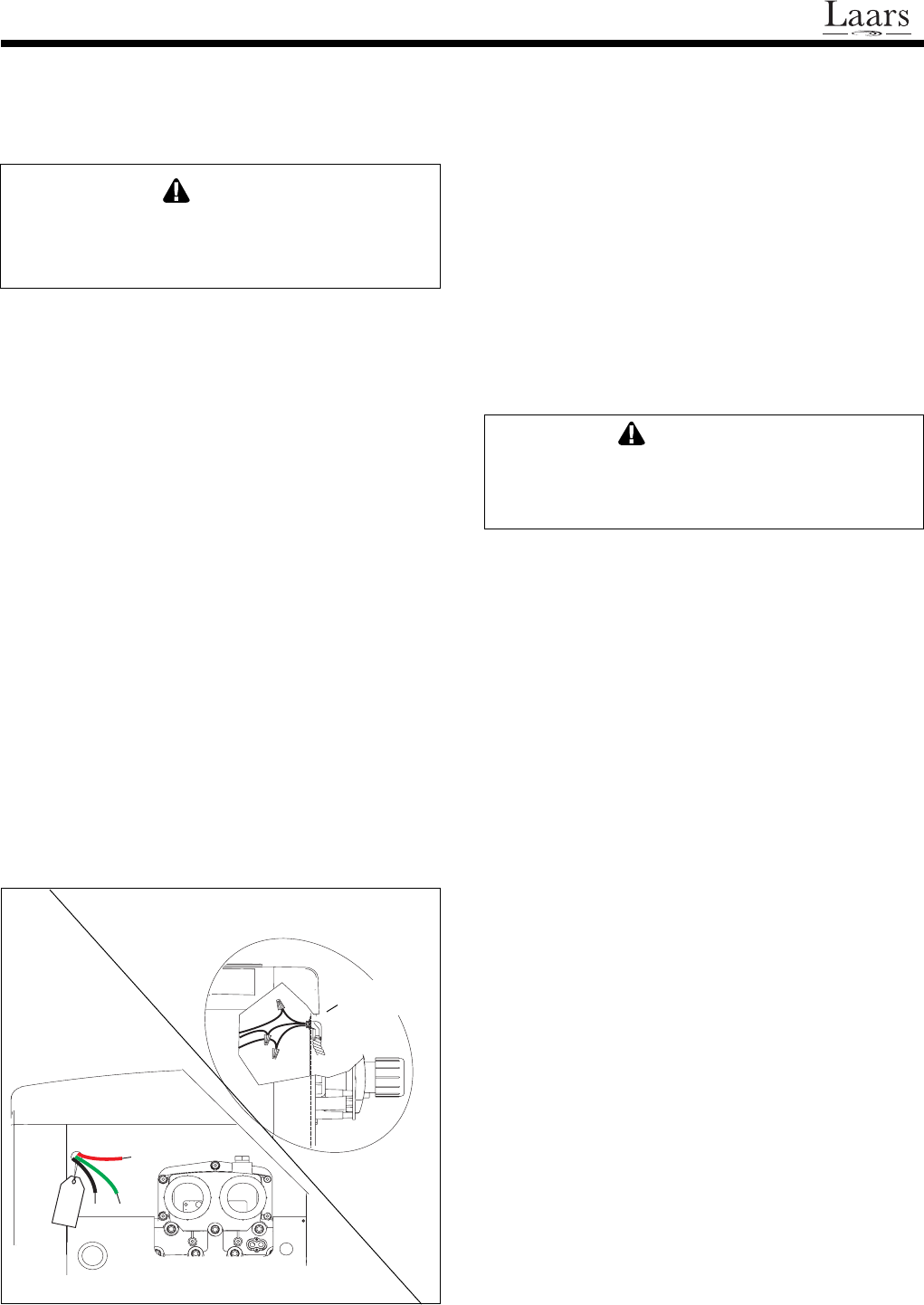

Wiring connections must be made exactly as shown

in the wiring diagram found on the inside of the heater

(see Figure 8 ). Grounding must be provided as required by

the prevailing electrical code. A separate bonding wire

MUST be provided as indicated in the following section

The heater comes factory-wired intended for use with

240 Volt, 60 Hz AC field electrical supply. To convert to

120 Volt, 60 Hz AC requires the changing of the fifteen-

pin connector assembly on the component raceway.

Remove the fifteen-pin connector from the receptacle

located directly below the fan intake on the raceway. All

the wires on the connector are red and the connector is

marked "240V". The fifteen-pin connector will have two

wires that lead to a two position terminal block located

next to the connector. Remove the two wires from the

terminal block. Take the fifteen-pin connector assembly

with the black wires from the installation and instructions

box. It is marked "120V". Connect the two long wires to

the two position terminal block. Either wire may be

connected to either tab on the terminal block, the

connections are not polarity sensitive. Plug the fifteen-pin

connector into the receptacle. The connector is keyed so it

will fit in only one orientation.

Electrical wiring must be in accordance with the

latest edition of the National Electric Code (NEC), ANSI/

National Fire Protection Association (NFPA) 70, unless

local code requirements indicate otherwise.

DO NOT connect power to the LX or LT pool

heater from the load side of a filter pump relay

or time clock.

To wire the Laars LX or LT heater:

1. Wire the heater to a 120V or 240V /60 Hertz (Hz)

electrical source.

2. Connect the wires from the source to the leads on the

right side of the heater in the space behind the

raceway (see Figure 9).

NOTE: No external junction box is required.

2H-2. Bonding

The National Electrical Code and most other codes

require that all metallic components of a pool

structure, including reinforcing steel, metal fittings and

above ground equipment be bonded together with a solid

copper conductor not smaller than a number 8 wire. The

heater, along with pumps and other such equipment must

be connected to this bonding grid. A special labeled

bonding lug is provided on the right side of the heater to

accommodate this requirement.

2H-3. Auxiliary Time Clock Wiring

If you install a time clock to control the filter pump

operation, it is recommended that the time clock have its

own low voltage (Firemans) switch to turn off the heater

before turning off the pump . The switch should shut off

the heater about 15 minutes before the filter pump shuts

off. This will allow for a more efficient operation by

removing any residual heat contained in the heat

exchanger back to the pool.

To install a time clock auxiliary switch into the

heater circuit, follow these instructions (see Figure 10):

1. Remove heater door.

CAUTION

Figure 9. Field Wiring Connections.

WIRES

AS

SHIPPED

CONNECT

WIRES

INSIDE

HEATER

CONDUIT

ELBOW