LX and LT Pool Heaters

Page 13

Note: Only the small tab of the top groove will fit behind

the upper panel.

40. Remove the button plug type washer from the left

side cover panel. This panel will not be used in

reassembling the heater after a heat exchanger

reversal. However, the button plug washer will be

needed. Do not replace the cover panel over the vent

switch outlet. Doing so may cause the heater to

malfunction.

41. The gas line may enter the heater from either the left

side or the right side. Replace the button plug washer

in the hole through which the gas line will enter the

heater.

42. Use the button plug to cover the hole on the opposite

side of the heater.

Note: Be sure that the white fiber gasket is positioned on

the top flange of the exhaust vent.

43. Replace the top. While positioning the top, pull the

control panel through the hole and place it on top of

the panel. Fasten the top to the heater by replacing

the two hex head screws at the upper corners of the

raceway and the two philips head screws at the upper

corners of the rear panel.

44. Position the vent grill over the exhaust vent. Replace

the four philips head screws that fasten the vent grill

to the top.

45. Reinstall the control panel assembly into the top

panel. Slide the back of the bezel into place, then

lower the front, aligning the holes in the bezel with

the holes in clips on the tabs on the top panel.

Replace the two philips head screws located at the

front edge of the bezel.

46. Slide the raceway cover up to the top of the heater. Be

careful not to pinch any wires. Replace the two

screws on the bottom flange to hold the cover in

place.

47. Replace the front panel (door).

2I-2. Pool/Spa Piping Systems

Figure 15 illustrates typical piping for pool

equipment in pool/spa combination pools. With their

electronic temperature controls, the LX and LT are

particularly suited for this type of pool installation.

The heater must be protected from back-siphoning of

water, which can result in dry starts. If there is any chance

of back-siphoning, provide a check valve between the pool

and the filter pump inlet.

Arrangement of pool system components other than

as illustrated in these diagrams can affect the operation of

the heaters water pressure switch. Location of the heater

above or below the pool water surface can also affect

operation of the switch. In general, the pressure switch can

be adjusted to accommodate this effect if the heater water

connections are no more than six feet below the pool water

surface and no more than 15 feet above it. See instructions

for pressure switch adjustment in the heater start-up

section of this manual for more information about this.

Note that when pool equipment is located below the

pool surface a leak can result in large scale water loss or

flooding. Waterpik Technologies cannot be responsible for

such water loss or flooding or the damage caused by it.

Do not install a shutoff valve or any kind of variable

restriction in the water piping between the heater outlet

and the pool/spa.

Pool systems with water flow rates higher than 125

GPM require an adjustable external bypass at the heater.

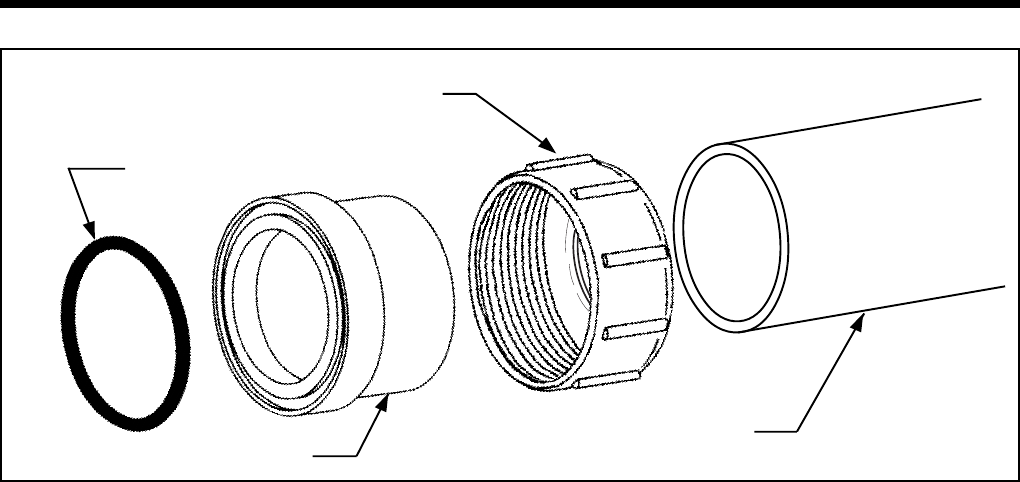

Figure 16. Piping to Heater.

O-RING

COUPLING

COUPLING NUT

PVC OR CPVC PIPE