VL SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

Pa

g

e 31 of 88

D. With the thermocouple disconnected,

connect the meter leads to the tube and

threaded end. Turn the power switch ON

and li

g

ht the pilot. Hold down the

OFF/PILOT/ON knob and allow the pilot to

heat the thermocouple for one to two

minutes. Take an open

circuit readin

g

and

compare with the chart below.

1) If the readin

g

is less than the

minimum or thermocouple is not

operatin

g

as described, replace the

thermocouple as outlined under

“PILOT AND THERMOCOUPLE

ASSEMBLY (GAS MODELS)” in

“REMOVAL AND REPLACEMENT

OF PARTS” then check for proper

operation.

3. If after checkin

g

and/or replacin

g

thermocouple, the pilot or main burners are still

not functionin

g

properly, then a problem in the

g

as combination control valve exists as well.

Replace the combination control valve as

outlined under “GAS COMBINATION

CONTROL VALVE” in “REMOVAL AND

REPLACEMENT OF PARTS” then check for

proper operation.

NOTE: Gas combination control valves are not

serviceable and should not be disassembled. Once

you have isolated the problem to this control,

replace it. Do not

attempt to repair the assembly.

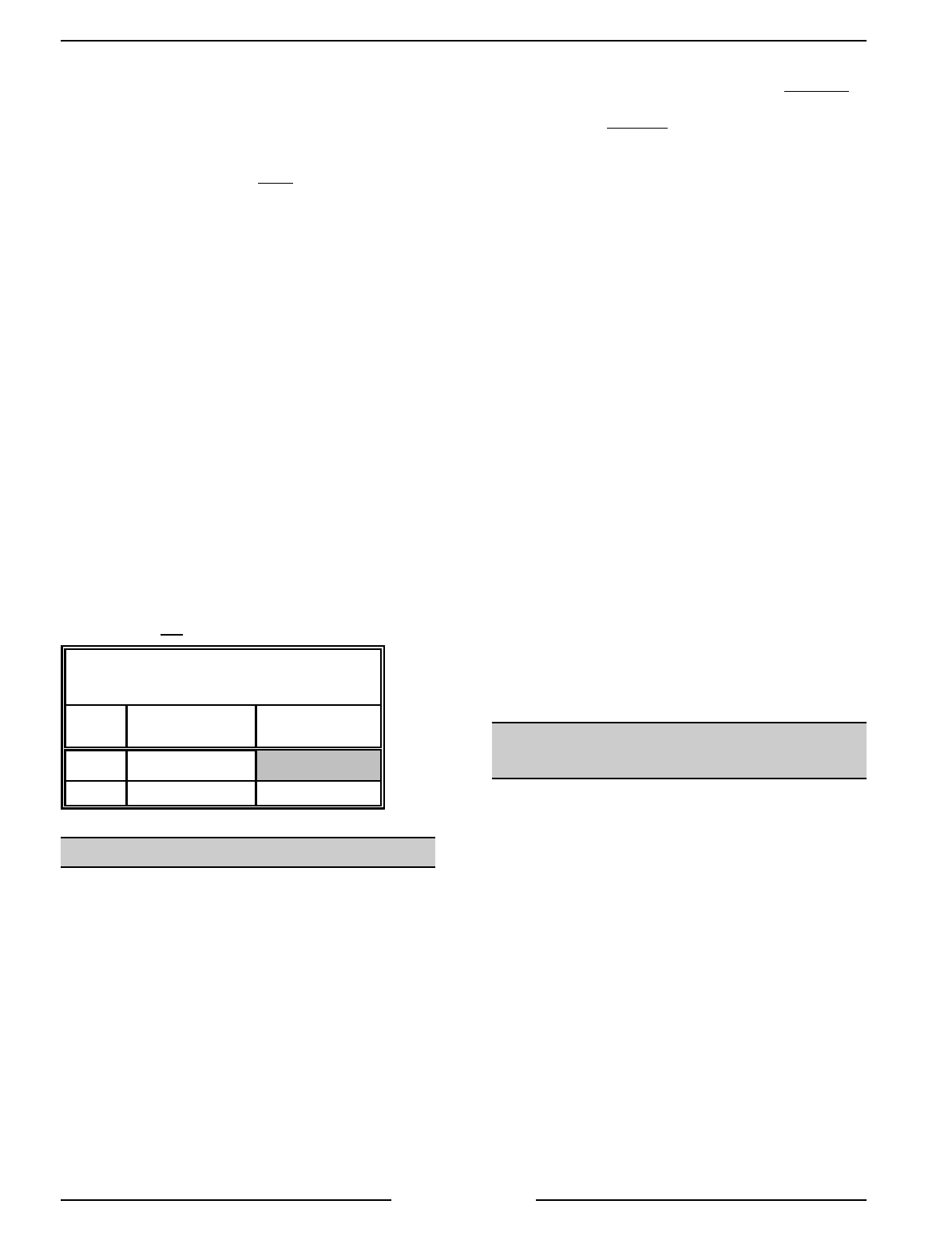

THERMOCOUPLE

DC MILLIVOLT

READINGS

CLOSED CIRCUIT

(CONNECTED)

OPEN CIRCUIT

(DISCONNECTED)

Typical 15

Range 10 - 20 20 - 35

GAS BURNERS

The main

g

as burners are located under the boiler

for heatin

g

and number five to seven dependin

g

on

the steamer model. They are made of aluminized

steel with lanced type ports and have adjustable air

shutters in the front. Fixed orifice type hoods extend

from the manifold to establish

g

as flow to each

burner.

Air Shutter Adjustment

1. I

g

nite the burners and allow to heat up for at

least five minutes.

2. Verify the manifold pressure as outlined under

“GAS MANIFOLD PRESSURE

ADJUSTMENT”.

3. Loosen the set screw on the burner bein

g

adjusted. Closin

g

the air shutter will decrease

primary air to the burner and openin

g

the

shutter will increase

primary air the burner.

4. Monitor the burner flame and set the air shutter

openin

g

as follows:

A. Open up the air shutter until the inner

portion (blue) of the flame lifts off the

burner port and then turn the air shutter

back until the flame touches the burner

port a

g

ain. A sli

g

ht tin

g

e of oran

g

e and

yellow in the flame is acceptable. An

extremely yellow flame indicates too little

primary air (oxy

g

en), producin

g

poor

burnin

g

characteristics and the heatin

g

efficiency drops off. A by product of this

would be soot (carbon).

Factory air shutter settin

g

s are: natural

gas - open approximately ½ inch;

propane gas - fully open.

5. After the air shutter adjustment is made, ti

g

hten

the set screw.

Inspection

Remove

g

as burners by liftin

g

burner up and slidin

g

it to the rear just enou

g

h to clear the

g

as orifice

hood. Lower the front end of burner and brin

g

it

forward under the

g

as manifold pipe. Inspect burner

for clo

gg

ed or dama

g

ed ports. Clean or replace as

necessary. When reinstallin

g

burners, assure that

locatin

g

pin is in the hole for proper positionin

g

and

to prevent burner from rollin

g

over.

AUTOMATIC IGNITION SYSTEMS

(GAS MODELS)

When the main power switch is turned ON and the

i

g

nition control modules reset switch is in the ON

position, the i

g

nition control module is ener

g

ized

with 24VAC between terminals five and six.

Hi

g

h volta

g

e is sent from terminal nine to the spark

electrode and an output of 24 volts is sent from

terminals two and three to the pilot coil in the

combination valve, allowin

g

g

as to flow to the pilot.

The sparkin

g

will continue for 90 seconds or until

the flame sensor has confirmed that an adequate

pilot flame is present.