Operation

Overloads and motors are both rated by class. The class is

defined by the NEC to determine the maximum time to

trip. A Class 20 overload, for example, has a typical trip

delay of 20 sec. or less at 600% current and normal

operating temperature. This allows for high motor inrush

current for 20 sec. while the motor is ramping up to

synchronous speed. The trip time, however, is based on

the percentage of overload. The higher the overload, the

shorter the time.

T1

T2 T3

97NO

98NO 95NC

96NC

10

20

30

RESET

TEST

MANUAL

AUTO

TRIP

5

130BX229.10

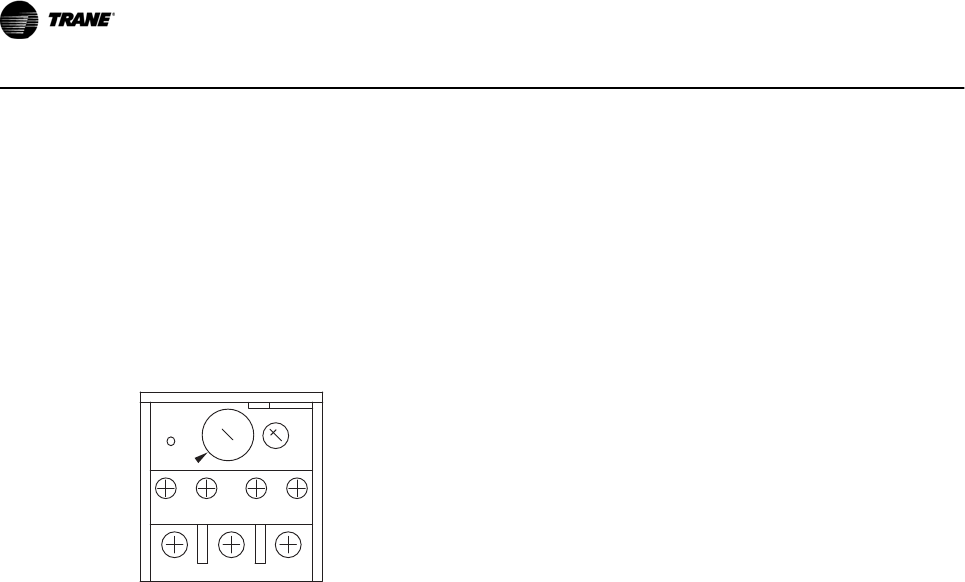

Figure 6.5 Sample Overload Device

Overload Function Setup

•

Set the overload current dial to the FLA of the

motor. DO NOT add the service factor of the

motor into the setting. A service factor of 1.2 x

FLA is designed into the overload.

•

Pressing the test pushbutton verifies the

operation of the overload. The overload should

trip when pressed. Use the reset pushbutton to

reset the overload after testing.

•

Reset is used to reset the overload after it trips. If

the overload is still hot, wait until the motor

reaches normal operating temperature before

resetting. The overload offers a manual (hand) or

auto reset selection. It is highly recommended to

operate in the manual factory setting to prevent

the risk of damage to the motor.

6.1.11 ECB Safety Interlock

General Information

The safety interlock feature prevents the drive or bypass

from operating. Only a fire mode command to run

overrides this function. For operation in drive or bypass

mode, the safety external interlock input contact must be

closed. External inputs include, but are not limited to, high

and low pressure limit switches, fire alarm, smoke alarm,

high and low temperature switches, and vibration sensors.

Operation

When an external safety input closes on ECB terminals 1

and 2 on connector X57, the option panel is in operational

mode. When open, power to the motor is disabled. The

bypass ignores all run commands except for fire mode

operation, when applicable. The drive display indicates

alarm 221, bypass interlock, meaning the problem is

external to the drive. A factory installed jumper between

X57 terminals 1 and 2 allows the unit to operate when no

safety input is connected. This jumper must be removed

when connecting in a safety interlock circuit.

Safety Interlock Function Setup

•

Remove factory-installed jumper between ECB

connector X57 terminals 1 and 2 on drive control

terminals.

•

Wire safety input to connector X57 terminals 1

and 2.

•

For technicians familiar with connecting to drive

terminals 12 and 27 for safety interlock, be aware

that ECB bypass operation will NOT stop with the

external fault report. Use terminals 1 and 2 on

connector X57, as indicated, for bypass control.

6.1.12 ECB Common Run/Stop

General Information

The common run/stop function provides remote run and

stop control of the motor while in either drive or bypass.

Without common run/stop, the motor would automatically

run at full speed whenever the bypass is activated. The

remote signal provides drive control as well as bypass

control, making this one input common to both. Common

run/stop is enabled by factory default. When used with the

run permissive function, common run/stop permits run

request operation in bypass.

Operation

A user supplied remote run command wired to drive

terminals 13 and 18 initiates remote drive or bypass

operation. Common run/stop can also be activated by

hand on the keypad or through serial communication.

Operation in either drive or bypass is determined by drive

or bypass mode selection, not the run/stop command.

Prior to Enabling Common Run/Stop

•

Complete the start-up procedure to verify motor

rotation direction in bypass is correct and that

the system is ready in all respects for continuous

full speed operation in bypass.

Common Run/Stop Setup

•

Wire a remote run/stop to drive input terminals

13 and 18 (default run input). Ensure that

parameter 18 is programmed for run (default

setting).

Electronically Controlled B...

6-12 BAS-SVX49A-EN