Teledyne API Model M201E NH

3

Analyzer Operator Manual Calibration Procedure

05206H DCN5910 19

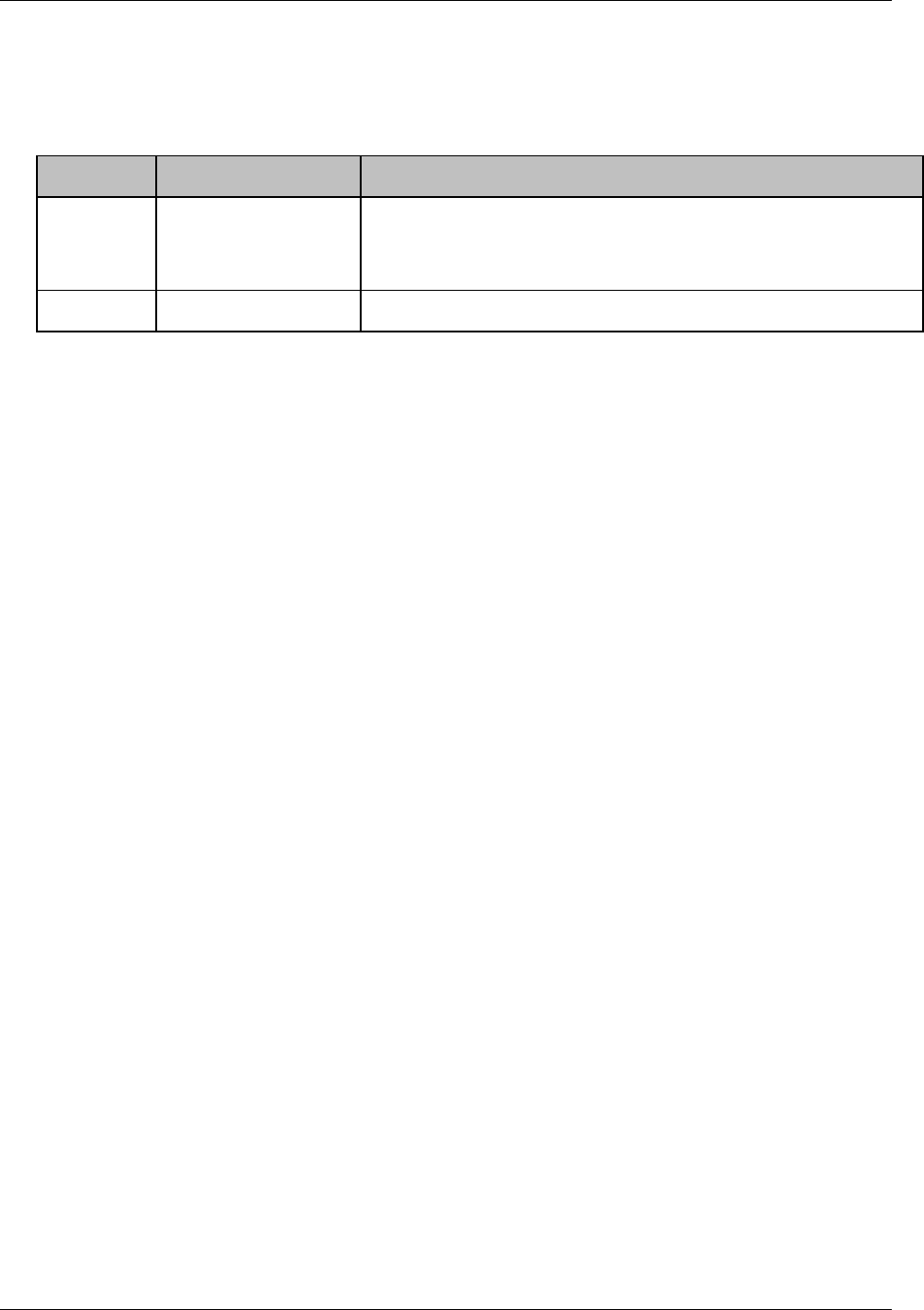

Table 2-4. NO Calibration Procedure - NO Gas through the SPAN Port

Step No.

Action Comment

1. Press CALS The M201E enters the calibrate mode from sample

mode. The NO gas is supplied through the SPAN inlet

port on the rear panel of the M501 NH

3

,.

2 Table 2.3 Follow Steps 2 to 5 in Table 2-3.

Notes:

Both the TN

x

and NO

x

channels must be spanned individually with nitric

oxide gas. When you span the NO

x

channel both the NO and NO

x

concentrations must be manually inputted.

It is recommended that the calibration of both the TN

x

and NO

x

channels

be done at the same time.

Always confirm that SPAN gas is flowing past the sample or span port on

the rear of the M501 NH

3

, converter. There should always be some

excess flow. If insufficient flow is supplied to the analyzer ambient gas will

be entrained and the span values will be incorrect. However, it is important

not to over pressurize the analyzer.

It is a good idea to allow the analyzer to sample span gas for extended

periods following span calibration. Large drifts can signify leaks or indicate

an issue with the span gas source.

If after spanning with nitric oxide, the analyzer slopes are out of range

conduct the following:

Confirm the gas sources are good. Usually the bottle is certified to

a known level of nitric oxide. The bottle should be balanced with

nitrogen. Try not to use the same regulator for nitric oxide as was

used on ammonia. This also holds for the tubing between the

different bottles and the mixing source (calibrator).

Confirm the zero reading is good by delivering Zero gas.

Confirm that the concentration delivered to the analyzer is equal to

what you entered under the CONC menu NOx and TNx.

Leak check both the M501 NH

3

, and analyzer together.

Using section 11.6.5 of the M200E manual confirm that the PMT

sensor hardware calibration is set correctly.