Page 22

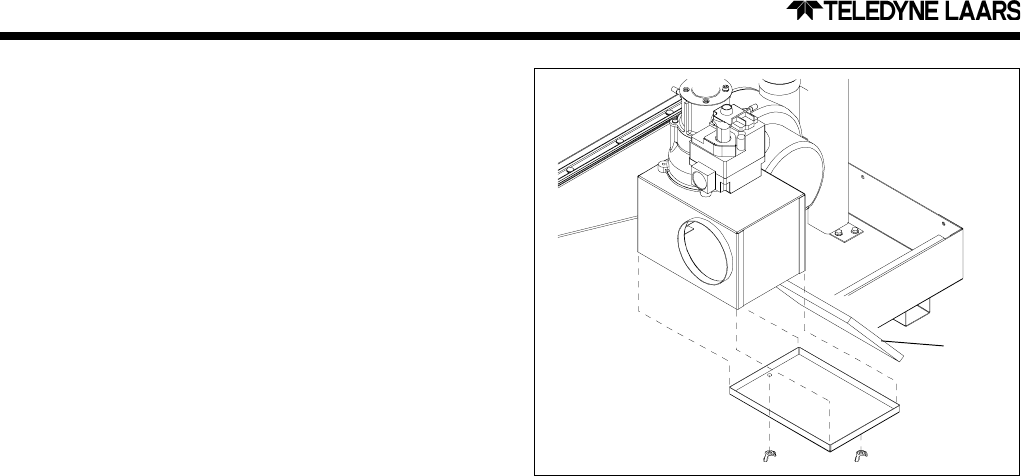

The filter should be replaced annually in normal

service. Heavy use of the heater or operation in adverse

environments may dictate more frequent replacement,

however. It can be removed through the bottom of the

filter box as illustrated in Figure 30.

Remove the wing nuts retaining the bottom panel

and remove the panel. Grasp the bottom edge of the

filter and pull it downward and to the right. Replace it

only with the specified part available from a Teledyne

Laars representative. Push the replacement filter into

the tracks at the front and rear of the filter box.

4E. Electrical Trouble Shooting

This section describes procedures for checking

the electrical power and control components of the

heater one at a time and in the order they appear in the

control circuit.

These procedures require a Volt-Ohm meter with

0-150 VAC VAC range, and 0-1000 Ohm resistance

range. Figure 31 shows the power and control circuits,

and where to take measurements. Location numbers in

circles have been added, and will be referenced in the

following sections.

As stated at the beginning of this manual, some

of these procedures are hazardous. Only a qualified

service technician should service the heater.

4E-1. 115V Electrical Power Supply

The electrical components of the Hi-E2 pool

heater are designed to operate with supply voltage

ranging from 103V to 126V at 60 Hz. Measure supply

voltage at the “hot” and “neutral” wirenut connections

in the heater electrical junction box (identified as

points A and B on the wiring diagram). If no voltage is

present, correct this external to the heater. Circuit

breakers, time clock settings or similar devices may be

the problem. Voltage outside of the above range may

be due to poor wiring, poor connections, other loads

5. Igniter - The hot surface igniter is a ceramic

element which becomes very hot when

electrical power is applied to it. It functions

both as an igniter and as flame sensor. As a

sensor, it is the electrode through which the

ignition control detects “rectification” of

current passed through the flame. Inadequate

rectification indicates an unsatisfactory flame

condition. The ignition control responds to

the flame signal provided by the ignitor.

6. Venturi Pressure Switch - This switch

verifies that air is flowing through the

combustion system by sensing pressure

reduction at the venturi throat (relative to

pressure at the venturi inlet). It shuts off the

heater if air flow is inadequate.

7. Limit Switches - Two limit switches prevent

excessive water temperature - one within the

heat exchanger and one for water leaving the

heater. If either senses excessive temperature,

burner operation is interrupted.

8. Water Pressure Switch - This control senses

whether or not water is available to the heater

by measuring back pressure inside of the heat

exchanger. If the pool water pump fails or the

water filter is blocked, the pressure switch

prevents operation of the burner. It can be

affected by the installation conditions as

discussed earlier in this manual.

9. Burner Temperature Limit Switch - This is

a single-use switch which detects abnormal

burner temperature. It is a disc-type switch

which is held against the burner plenum by a

sheet metal bracket. It has the appearance of

an automatic-reset switch in that it has no

reset button. However, it will reset only if

cooled to -31

o

F, and therefore will not

recycle. The burner limit switch prevents or

interrupts burner operation if the burner

plenum becomes too hot.

10. Vent Limit Switch - The vent limit switch

protects the vent system from excessive

exhaust temperature. It is located on the vent

diffuser above the combustion blower. It

interrupts burner operation if temperature

becomes too hot for the plastic materials used

to vent the heater.

See the earlier section entitled Start-up and

Adjustment for the normal sequence of operation.

4D. Combustion Air Filter

The combustion air filter is a rectangular foam

filter located in a box near the bottom of the control

compartment.. The filter removes lint and large scale

dust particles to prevent blockage of the burner media.

Figure 30. Air Filter Replacement.

Filter