Page 20

SECTION 4.

Maintenance and Service

WARNING

SERVICING SAFETY

Some of the servicing procedures for the Hi-

E2 pool heater are hazardous because they

involve fuel gas, electricity, moving parts and

procedures which require testing or temporary

bypass of safety controls. For this reason, the

heater must be serviced only by a qualified

professional service technician.

IMPROPER SERVICE HAZARD

The Hi-E2 pool heater incorporates unique

design features. Incorrect service of this

heater can result in personal injury or damage

to property. To avoid such hazards, the heater

must be serviced only by a qualified

professional service technician.

4A. General

A qualified professional technician must service

the Hi-E

2 pool heater using Teledyne Laars service

procedures. Before calling for service, however, the

owner should check for obvious problems. The other

components in the pool system, including pump, filters

and strainers, water valves, gas supply, electrical

power and time clocks, have an effect on heater

operation.

Confirm that the Flex Temp heater control is set

to “pool” or “spa” and that the corresponding

temperature knob is set high enough to make the heater

operate. Make sure the pump is operating, that the

filter and strainers aren’t clogged, that there are no

mis-positioned water valves, that the gas or electric

power supplies aren’t shut off and that time clocks are

3H-2. Professional Inspection

Inspection by a qualified professional technician,

performed at least once a year by a qualified

professional technician, are required to keep the heater

operating efficiently through the years. The following

basic checks should be performed.

1. Inspect the condensate disposal system to be sure

that condensate flows freely.

2. Replace combustion air filter.

3. For heaters installed with combustion air or vent

piping, inspect screens at the inlet or outlet of

these pipes. Clean screens as necessary to assure

free flow (See illustrations in combustion air and

vent pipe installation section).

4. Make sure that the pressure switch operates

properly by shutting the filter pump off and on a

few times. The burner should go off immediately

after the pump stops. An ignition sequence

should start shortly after the pump is turned

back on.

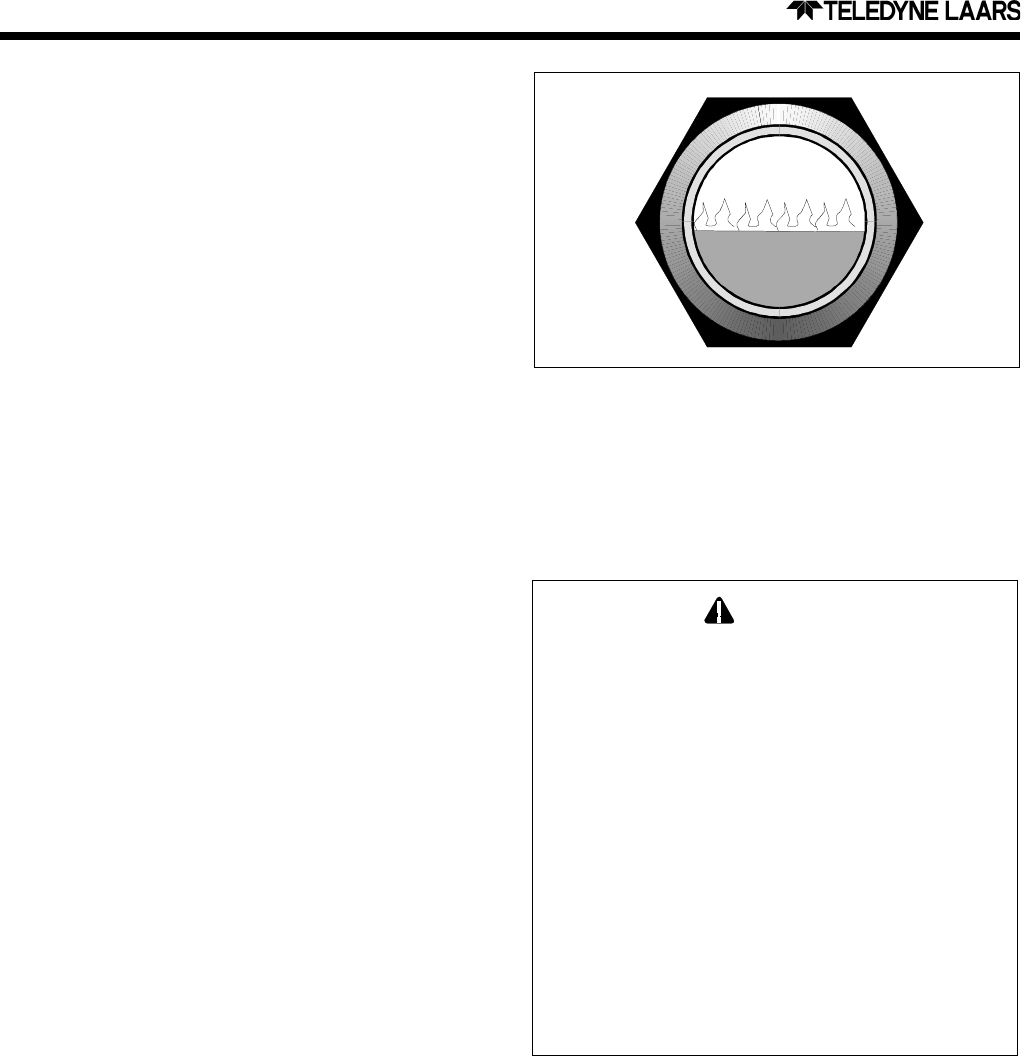

5. Make a visual check of the main burner flame.

The flame can be seen in a mirror/viewport

arrangement in the upper part of the heater. The

flame should be light blue and the burner surface

should be dark, with only a few glowing fibers

(see Figure 28).

6. Inspect the gas and electronic controls, including

the following:

a. High temperature limit switch

b. Water pressure switch

c. Venturi pressure switch

d. Automatic gas valve

e. Burner temperature limit switch

f. Vent limit switch

g. Temperature control

h. Control circuit fuse

7. Perform a temperature rise test in accordance

with Section 2L.

8. If the heater is equipped with a pressure relief

valve, clean any accumulated corrosion and make

sure that water runs freely through it.

9. Inspect the outside of the combustion chamber

and burner for corrosion and indication of

improper operation.

10. Regularly inspect electrical controls for

deterioration. Repair and replace as necessary.

NOTE: Keep this manual in a safe place for

future reference by you and your professional

technician when inspecting and servicing the heater.

Figure 28. Burner Flame (visible near top of heater in

mirror).