NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

15

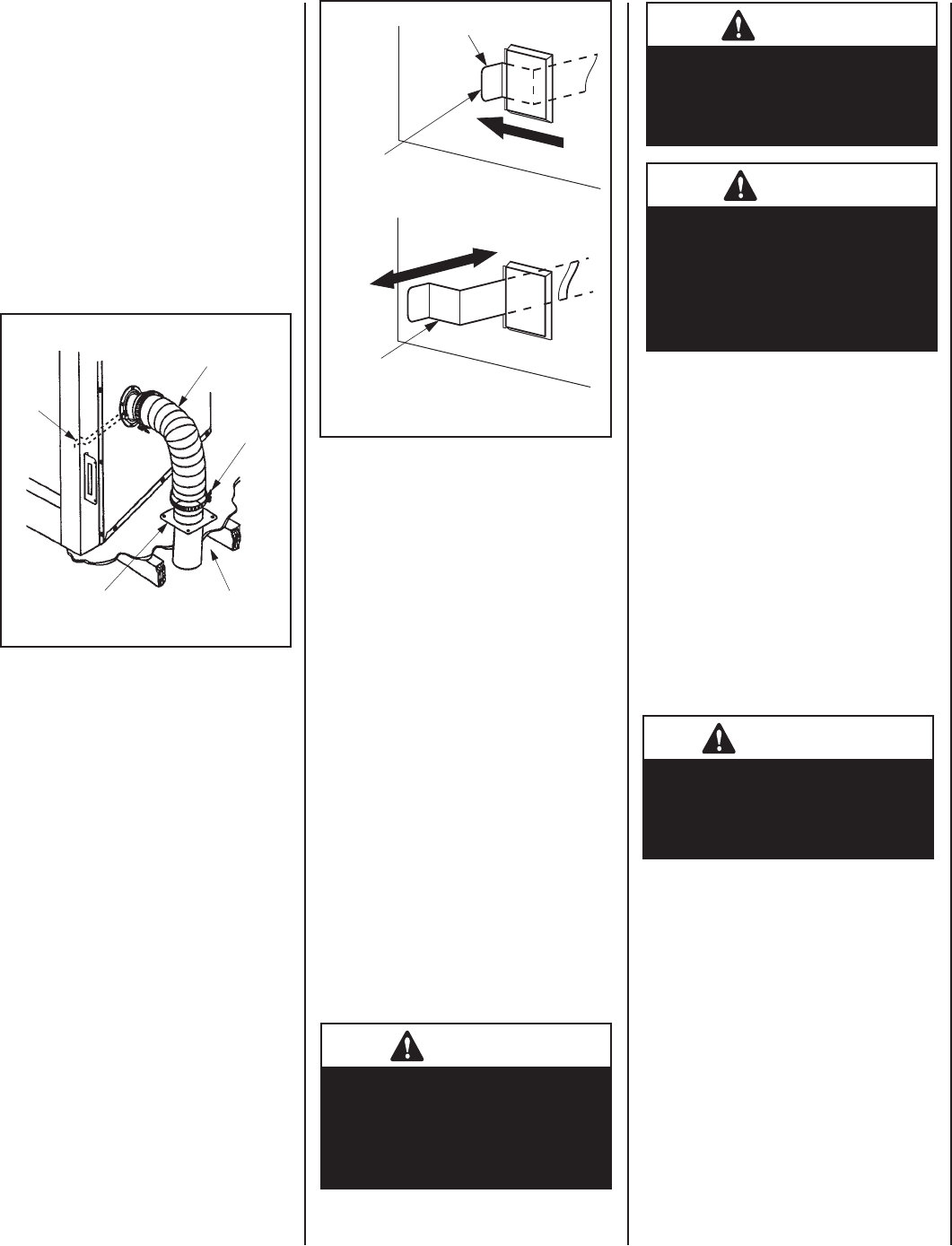

Gas Line Connection

Install a 1/2” gas supply line through fi replace

wall for connection to a decorative gas appliance

inside the fi rebox. Outside, the gas supply line

connects to a gas shut-off valve recessed fl ush

into the wall or fl oor. The valve should be con-

trolled by a removable valve key for safety.

Always plumb gas line installation per local

codes. Check all connections using a gas leak

test solution (also referred to as bubble leak

solution). Note: Using a soapy water solution

(50% dish soap, 50% water) is an effective

leak test solution but it is not recommended,

because the soap residue that is left on the

pipes/fi ttings can result in corrosion over time.

Never test any gas line connection with a match

or open fl ame.

This provision is intended for connection to

a decorative gas appliance incorporating an

automatic shut-off device and complying with

the Standard for Decorative Gas Appliances for

installation in vented fi replaces, ANSI Z21.60

(1991) or American Gas Association draft re-

quirements for Gas-Fired Log Lighters for Wood

Burning Fireplaces, Draft No. 4 dated August,

1993. Install in accordance with the National

Fuel Gas Code, ANSI Z223.1. This complies

with the revised U.L. 127 standard.

If you’re installing a gas line, connect it before the

fi replace is framed and enclosed in the fi nished

wall. The gas knockout is determined by the

indentation located at the bottom and slightly

off center in the side refractories. THE KNOCK-

OUT IS ALWAYS REMOVED FROM INSIDE THE

FIREPLACE. DO NOT REMOVE THE KNOCKOUT

UNLESS YOU ARE INSTALLING A GAS LINE.

If removal is attempted from the outer wrap-

per, side refractory damage may occur. With a

medium-sized hammer, lightly tap the surface of

the indentation. The refractory material is very

thin in this area and is easily removed. Once

a small hole has been made, continue tapping

until you have reached suffi cient diameter for

the gas line to fi t through. The entire knockout

does not have to be removed. Remove insulation

in the gas line channel.

Always check local building codes. Instal-

lation of the BFK36 Blower Kit must comply

with local regulations as well as the National

Electric Code.

Combustion Air Kits

These appliances are equipped with an outside

(make-up) air door and integral actuator arm and

an outside air kit with a collar, duct and hood

(90L83). The appliance must be installed with

an outside air vent system (Figure 38). These

kits come complete with detailed installation

instructions and all components necessary in

completing a combustion air vent system.

Figure 38

After completing the installation of the com-

bustion air vent system the actuator arm must

be put in service and tested to ensure proper

operation before completing any enclosure

around the fi rebox. Failure to do so may result

in extensive and costly rework.

Locate the actuator arm along the right side

of the appliance fi rebox opening and refer

to Figure 39. To operate, push the end of the

actuator to the left as shown in Figure 39, until

it "pops" free of its "locked" position. Pull the

actuator forward to open the combustion air

door, and push it back to close. To "lock" the

combustion air door closed, ensure the actuator

is pushed all the way back then push the end

of the actuators to the right until the step in the

actuator moves behind the appliance front face

within the slotted opening.

Operate the actuator through several cycles

including the "lock position. Ensuring proper

operation and freedom of movement. Return

the actuator arm to the locked position.

Air Inlet Assembly

(Attach To Floor)

Non-Combustible

Class 0 Or Class 1

6 Inch Air Inlet Duct

Actuator

Arm

Clamp

Securely

At Top And

Bottom

Vented Crawl Space

“Pop” Actuator to

the Left Before

Initial Use

Pull Forward to Open,

Push Back to Close

Combustion Air

Actuator

WARNING

This fi replace has not been tested

with an unvented gas log set. To

reduce risk of fi re or injury, do

not install an unvented gas log

set into this fi replace.

CAUTION

When using the decorative gas

appliance, the fi replace damper

must be set in the fully open

position.

CAUTION

Plumbing connections should

only be performed by a quali-

fi ed, licensed plumber. Main

gas supply must be off when

plumbing gas line to fi replace

or performing service.

IMPORTANT

Repack insulation material in

square hole around gas line,

interior and exterior of fi replace,

to seal.

COLD CLIMATE INSULATION

If you live in a cold climate, it is especially

important to seal all cracks around the fi re-

place and wherever cold air could enter the

room with noncombustible material. Surround

material must be caulked where it meets the

black metal facing of the fi replace to avoid cold

air intrusion. Use noncombustible caulking

material only on fi replace facing to seal. Also,

the outside air inlet duct should be wrapped

with noncombustible insulation to minimize

the formation of condensation. Do not place

insulation materials directly against the chim-

ney sections.

Note: 1" (25 mm) air space must be preserved

for all materials extending for any continuous

length adjacent to the chimney.

Figure 39