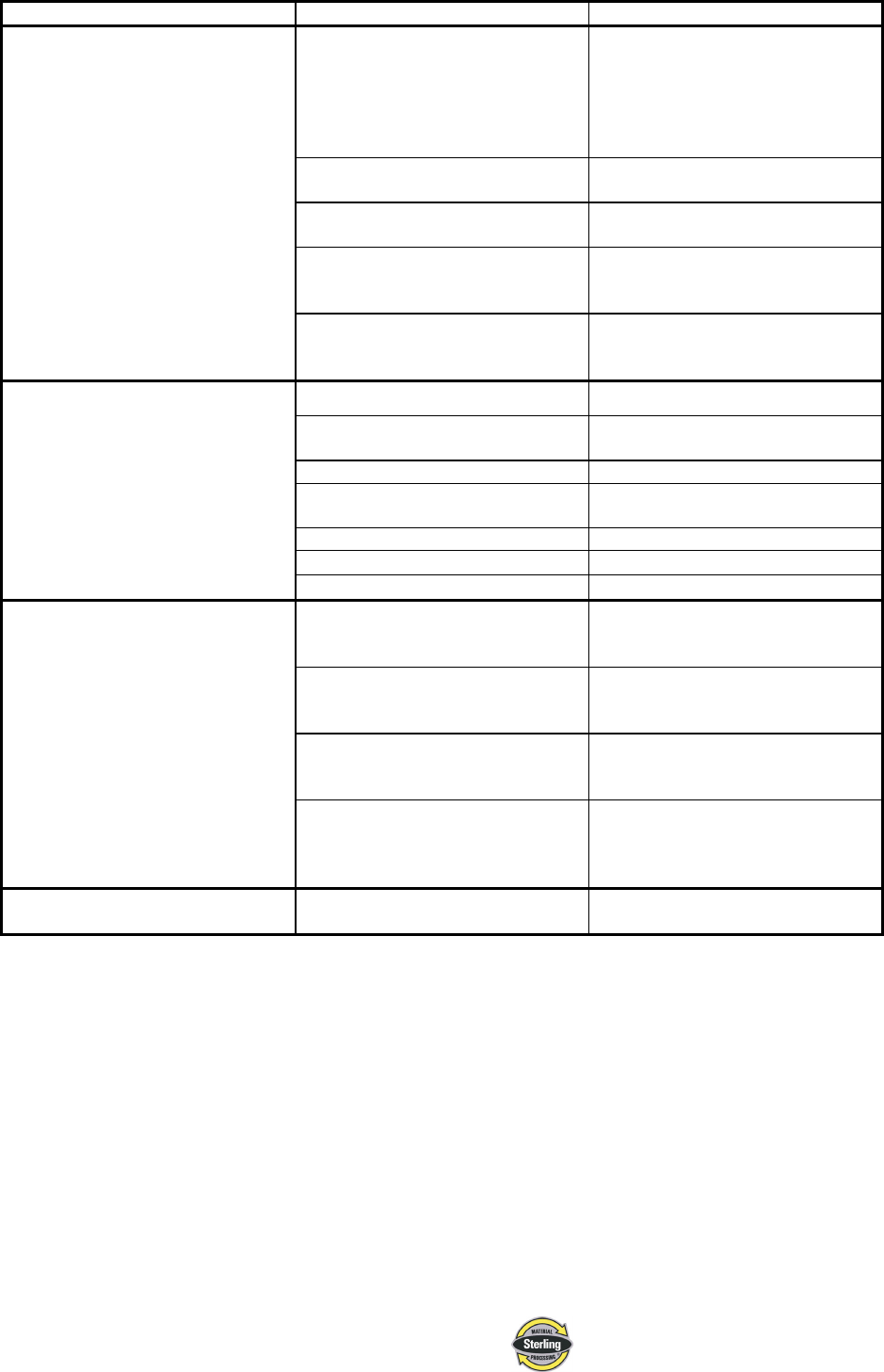

Page 54 SMD Series Dehumidifying Dryers

Problem Possible cause Corrective action

Process temperature set too

high due to operator error.

Check resin manufacturer’s data

sheet for proper drying

temperature. Make sure plant

personnel are aware of the

correct process temperature set

point.

High temperature alarm not set

properly.

Reset high temperature alarm.

Process set point is out of

acceptable range.

Restore temperature controller

to factory pre-sets.

Function set for degrees Celsius

(ºC), set point at degrees

Fahrenheit (ºF).

Verify correct Celsius or

Fahrenheit settings.

Material in drying hopper cakes,

or meltdown occurs.

Process thermocouple not in

airflow.

Verify that the thermocouple is

properly installed in the inlet

tube.

Leaking process air hoses. Repair or replace.

Dryer operates beyond its

capacity.

Check dryer and drying hopper

sizing.

Bad dew point sensor. Replace.

Fouled dew point sensor

manifold.

Clear obstruction. Air should

flow freely through sensor.

Coalescing filter saturated. Replace with new element.

Large particle filter dirty. Replace with new element.

Poor dew point performance.

Membrane contaminated. Replace.

The internal mechanism is not

inserted properly into the

housing.

Properly insert the internal

mechanism into the housing.

The power supply is not

connected to its terminals

properly.

Properly connect the power

supply to the power supply

terminals.

No power is supplied, or the

supplied power is not within the

specified range.

Supply a voltage of 85 to 125

VAC to the power supply

terminals of the controller.

Nothing displays when the

controller is turned on.

Disconnect switch or Control

Power switch not set to ON.

Control Power fuse blown.

Check control power fuse for

continuity. Turn disconnect

switch and control power switch

ON.

No setting change possible on

temperature controller.

The key protection switch is set

to ON.

Set the key protection switch to

OFF.