Page 12 SMD Series Dehumidifying Dryers

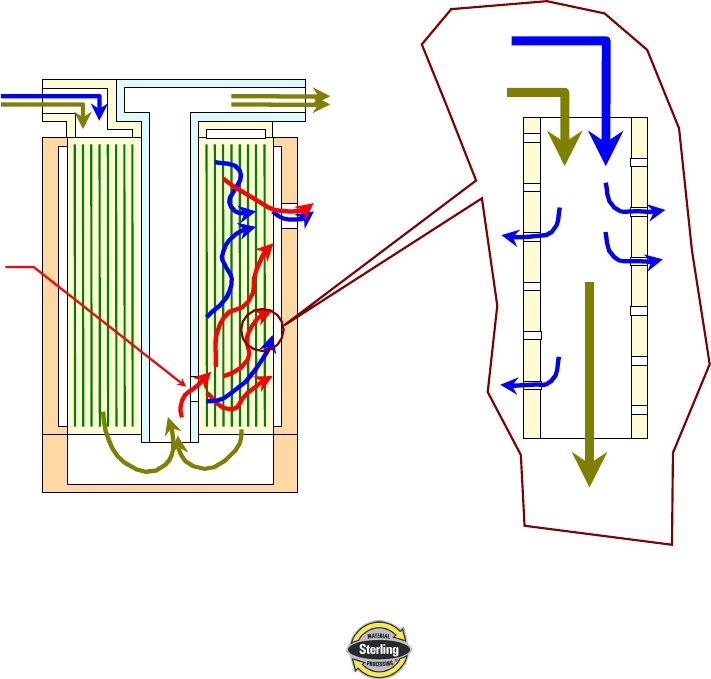

1-6 The Drying System

Sterling Membrane Compressed air dryers, take a small percentage

of the dried gas and direct it back in a sweeping pattern through the

module shell. This provides a driving force to remove the moisture

with the minimum purge required.

The Moisture Vent Compressed Air Dryer, consists of thousands

of hollow-fiber membranes made of tough temperature and

pressure resistant plastic. The inside surface of these hollow fibers

is coated with an ultra-thin layer of a second plastic that performs

the actual water-vapor from air separation. This second coating

allows air to pass through it over 20,000 times easier than it allows

water to pass. As a result, moisture is expelled rapidly with very

little air loss. Two-stage drying provides the option of using the

Moisture Vent directly at the point-of-use in combination with a

refrigerated air dryer.

As a single stage unit, the dryer provides consistent performance

from 60°F to -20°F outlet dew point. When combined with a

refrigerated air dryer, the Moisture Vent system will suppress or

reduce the inlet pressure dew point to below -40°F with very low

sweep requirements.

Figure 2

Typical Dryer Air Flow Schematic

Water

Air

Purge

Dry Air

Humid Air

Dry Air