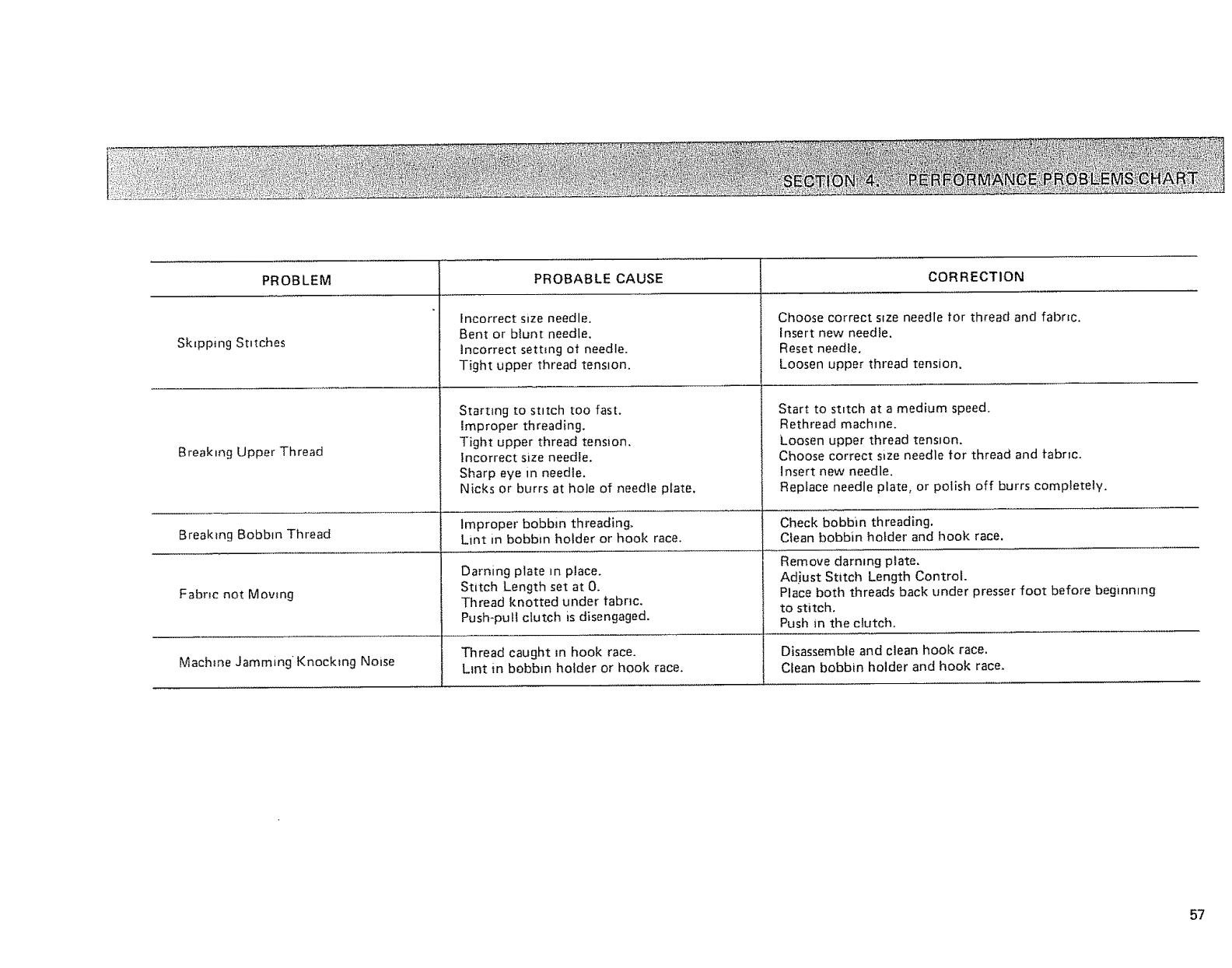

PROBLEM PROBABLE CAUSE COR RECTION

SMpping Stitches

Breaking Upper Thread

Breaking Bobbin Thread

Fabric not Mowng

Machine Jamming Knocking Noise

incorrect size needle.

Bent or blunt needle,

incorrect setting ot needle.

Tight upper thread tension.

Starting to stitch too fast.

Improper threading.

Tight upper thread tension,

incorrect size needle.

Sharp eye in needle,

Nicks or burrs at hole of needle piate,

Improper bobbin threading.

Lint in bobbin holder or hook race.

Darning plate in place.

Stitch Length set at O.

Thread knotted under fabric.

Push-putt clutch is disengaged.

Thread caught m hook race.

Lmt {n bobbin holder or hook race.

Choose correct size needle for thread and fabric.

Insert new needfe.

Reset needle.

Loosen upper thread tension.

Start to stitch at a medium speed.

Rethread machine.

Loosen upper thread tension.

Choose correct slze needle for thread and fabric.

Insert new needle.

Replace needle plate, or polish off burrs completely,

Check bobbin threading.

Clean bobbin holder and hook race,

Remove darning plate.

Adiust Stitch Length Control.

Place both threads back under presser foot before beginning

to stitch.

Push in the clutch.

Disassemble and clean hook race.

Clean bobbin holder and hook race.

57