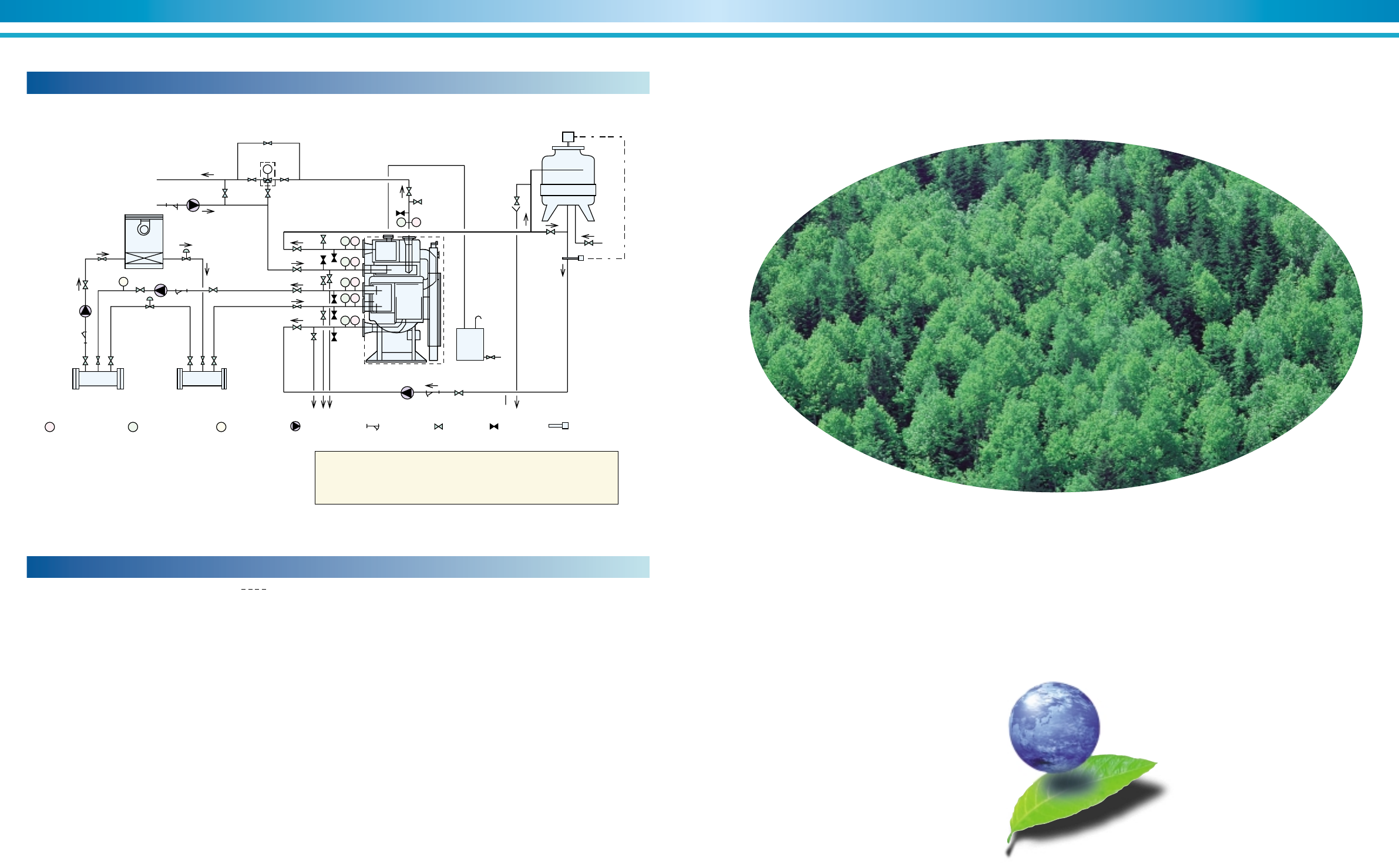

SUPER ABSORPTIONENVIRONMENTALLY FRIENDLY TECHNOLOGY

1. Work outside the area surrounded by this line

shall be under-

taken at the expense of the owner.

2. Refer to the Dimensions diagrams and specification tables for pipe

connections and diameters.

3. Determine the locations of the chilled, cooling and hot water pump in

due consideration of the pump’s hydrostatic head.

As standard condition, the machine should not be subject to a

pressure larger than 8 kg/cm

2

G. at any water headers.

4. Concerning the temperature control of cooling water, refer to the

section of ”control method of cooling water temperature”.

5. Provide a thermometer and a pressure gauge at the outlet and inlet

of cooling water temperature.

General remarks on piping work

6. Provide an air vent valve in each of the chilled, cooling and hot water

lines at a point higher than the header for chilled, cooling and hot

waters.

7. Lay pipes from the cover of the evaporator, absorber and generator

to drain ditch.

8. Provide a bleeder in the cooling water line for control of water quality.

9. All external water piping are to be provided with JIS 10k welding flanges

by the customer.

10.Be sure to design the location of cooling tower to prevent

contamination of cooling water by exhaust gas from flues.

Supply

Header

Return

Header

Secondary

Chilled

Water pump

Bypass valve

Primary

Chilled water pump

Air

Conditioner

Hot water

Pump

Hot water

3 way valve

Cooling water pump

Cooling

tower

Make up

water

To drain

To drain

F

CC

T

T

T

T

T

P

P

T

P

P

P

P

Air vent

In order to prevent freezing up of chilled water when the chilled water

gets a stop signal, continue the operation of the primary chilled water

pump and secondary chilled water pump and air conditioner during

dilution cycle operation of the chillers.

T

: Thermometer

P

: Pressure gauge

F

: Flow meter

: Water pump : Strainer

: Valve

: Valve

: Thermostat

Tank

above

1m

3

Utility

1.Unit selection tables

2.Pressure drop curves

3.Installation and application data

4.Management of cooling water quality

5.Installation examples

Typical piping diagram-laying (LE)

Figure 61. Typical piping diagram