SUPER ABSORPTIONENVIRONMENTALLY FRIENDLY TECHNOLOGY

The heating cycle

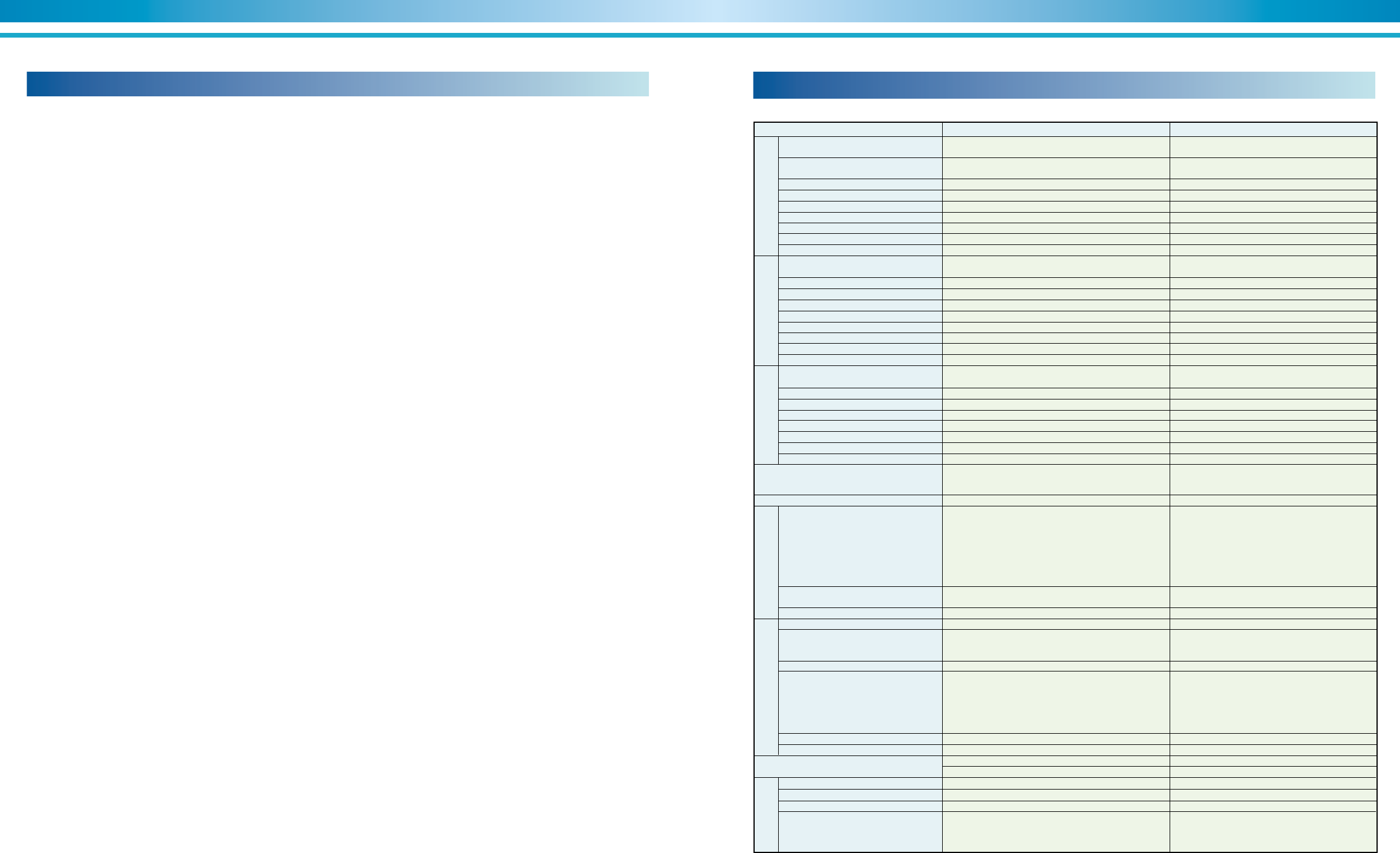

Item

Temperature

Flow rate

Max. working pressure

Hydraulic test pressure

Fouling factor

Material of tube

Water quality

Structure of water header

Manufacturing standard of water header

Temperature

Flow rate

Max. working pressure

Hydraulic test pressure

Fouling factor

Material of tubes

Water quality

Structure of water header

Manufacturing standard of water header

Temperature

Flow rate

Max. working pressure

Hydraulic test pressure

Material of tubes

Water quality

Structure of water header

Manufacturing standard of water header

Electricity

Shipment

Safety functions

Capacity control

Parts

Painting

Indication lamps

Display

External terminals

(no-voltage normal open contact)

Structure

Parts

Electrical wiring and piping

Place

Ambient temperature

Ambient humidity

Atmosphere

Option

Outlet : 6°C~12°C

Temperature difference : 3°C~10°C

Changes depending on chilled water temperature

difference (min. flow rate : 50%)

981~1,961kPa (10 ~ 20kg/cm

2

G)

Max. working press.✕1.5 times

0.196m

2

°C/kW (0.0002m

2

h°C/kcal)

No option

No option

No option

No option

Inlet : 20.0°C~33.0°C

Within the water flow range of each model

981~1,961kPa (10 ~ 20kg/cm

2

G)

Max. working press.✕1.5 times

0.196m

2

°C/kW (0.0002m

2

h°C/kcal)

No option

No option

No option

No option

Intel : 80°C~95°C

Within the water flow range of each model

No option

No option

No option

No option

No option

No option

Contact SANYO's representative

Multi-shipment

Cooling water flow switch

No option

No option

No option

No option

No option

No option

No option

No option

No option

No option

No option

No option

No option

Standard

Inlet : 13.0°C

Outlet :8.0°C

0.605m

3

/h•RT

784kPa (8kg/cm

2

G)

Max. working press. +196kPa (2kg / cm

2

)

0.088m

2

°C/kW (0.0001m

2

h°C/kcal)

Copper tube

Refer to JRA-GL02E-1994

Removal type

SANYO standard

Inlet : 31°C

Outlet : 37°C

1.215m

3

/h•RT

784kPa (8kg/cm

2

G)

Max. working press. +196kPa (2kg / cm

2

)

0.088m

2

°C/kW (0.0001m

2

h°C/kcal)

Copper tube

Refer to JRA-GL02E-1994

Removal type

SANYO standard

Inlet : 88°C

Outlet : 83°C

1.215m

3

/h•RT

784kPa (8kg/cm

2

G)

1,471kPa 15kg/cm

2

G

Material : Copper

Refer to JRA-GL02E-1994

Removal type

Japanese pressure vessel code

3 phase 380V 50Hz

(Voltage regulation : within ± 10%)

(Frequency regulation : within ± 5%)

One-section

•Refrigerant temperature supervision

•Chilled water freeze protection

•Chilled water floe switch

•Cooling water temperature supervision

•Generator temperature supervision

•Crystallization protection

•Motor protection

•Digital PID control by chilled water outlet temperature

•Inverter control of No.1 absorbent pump

Selected by SANYO

Munsell 5Y-7/1

•Operation : red

•Stop : green

•Equipment alarm : orange

•LCD

•Operation indication

•Stop indication

•Alarm indication

•Answer back indication

Indoor type

Selected by SANYO

Wiring : 600V grade polyvinyl chloride-insulated wire

Pipe : plicatube (flexible metal conduit)

Indoor

5°C~40°C

Relative humidity : Max. 90% (45°C)

Be sure the following are not present:

•Corrosive gas

•Explosive gas

•Poisonous gas

Installation condition

Control panel Control Hot water Cooling water Chilled water

Scope of order (LE)Scope of supply (LE)

1.Absorption chiller

(1)Lower shell

•Evaporator and refrigerant dispersion tray

•Absorber and absorbent dispersion tray

•Eliminators

(2)Heat exchangers

(3)Upper shell

•Generator

•Condenser

•Eliminators

(4)Pumps

•Absorbent pump(s) with isolating valves

•Refrigerant pump with isolating valves

•Purge pump

(5)Control panel

•CE marking (if requested according to the regulation).

(6)Hot water control valve

(7)Locally mounted controls and electric parts

•Temperature sensor

(8)Purge unit

•Purge tank

•Ejector and liquid trap

•Piping and various manual valves

•Palladium cell with heater

(9)Interconnecting piping and wiring

(10) Initial charge

•Absorbent (lithium bromide)

•Refrigerant

•Inhibitor

(11) Painting

•Main unit: Rust preventive paint

•Control panel: Finish paint

(14) Accessories

•Operation manual : One set

•Washer (for fixing foundation bolts) : One set

•Manometer : One piece

•Gasket and sealant for rupture disk : One set

(if requested according to the regulation).

2.Factory test

Tests below are carried out in the SANYO factory.

•Check of external dimensions

•Leak test (vacuum side)

•Hydraulic test for water headers

•Electric insulation resistance test

•Dielectric breakdown test

•Function test only for electric circuit and safety devices

•Performance test of one section shipping unit.

(one unit is tested when several units of the same model are

ordered for one project)

3.Scope of supply of the purchaser

(1)Unloading, transportation, and insurance depend on the

individual sales contractor between your company and SANYO

group.

(2)Foundations with foundation bolts.

(3)External chilled water, cooling water, and hot water piping

work including various safety valves. isolating valves, etc.

(4)Rupture disk, flange of rupture disk, bolts, nuts, piping work

and tank, etc, if necessary.

(5)External wiring and piping for the chillers including

necessary parts.

(6)Insulation for the chillers including necessary parts.

(7)Mating flanges, gaskets, bolts and nuts

•Inlet/outlet nozzle flanges for chilled water. (evaporator)

•Inlet/outlet nozzle flanges for cooling water. (absorber/condenser).

•Inlet/outlet nozzle flanges for hot water. (generator)

(8)Finish painting of the chiller.

(9)Cooling water inlet temperature control device.

(10) Furnishing electric wiring/piping of hot water control valve

including necessary parts.

(11) Various temp./press. gauges for water lines.

(12) Cooling tower(s), chilled water pump(s) , cooling water

pump(s) and hot water pump(s) and it’s auxiliary accessaries.

(13) Electric power supply (specified value).

(14) Supply of chilled water, cooling water and hot water at rated

conditions.

(15) Necessary tools, workers and materials for installation and

site test operation.

(16)

After-sales service and periodical maintenance of the chillers.

(17) Any other item not specifically mentioned in the scope of

supply.