1210 Oil-less Threading Machine

Ridge Tool Company4

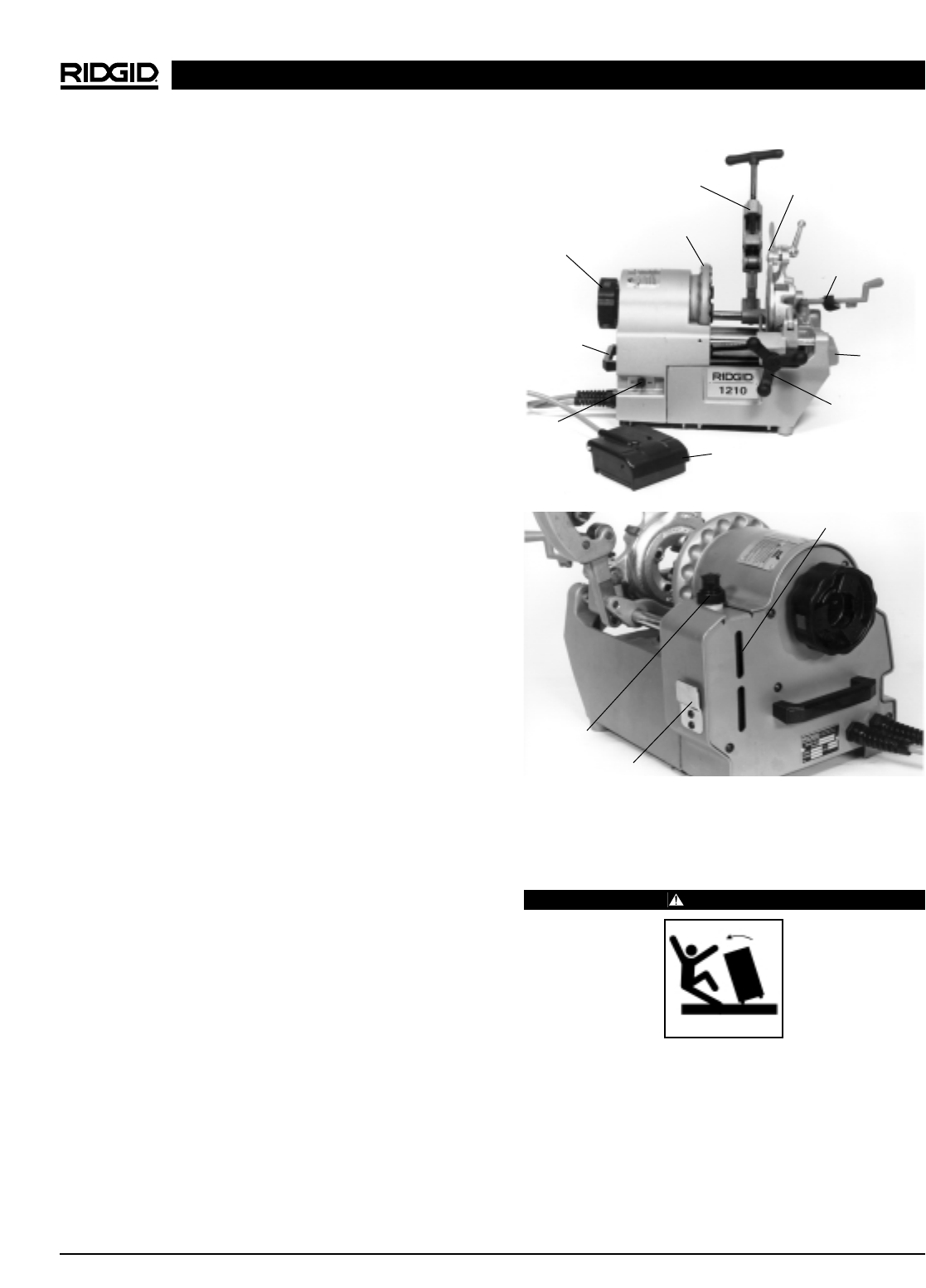

Figure 1 – 1210 Threading Machine

Machine Assembly

WARNING

To prevent serious injury, proper assembly of the

Threading Machine is required. The following pro-

cedures should be followed:

The 1210 Threading Machine can be used on a bench or

mounted to the Model 120 Stand. The No. 120 Stand is

a three-legged folding stand (Figure 2). Guide/pin as-

semblies are mounted on top of each leg to hold the

1210 Threading Machine in place.

Description, Specifications and

Standard Equipment

Description

The RIDGID Model 1210 Oil-Less Threading Machine is

an electric motor-driven machine that centers and chucks

pipe and rotates it while cutting, reaming and threading

operations are performed. Threading dies are mounted

in a quick-opening die head. An integral coolant system

is provided to reduce the temperature of the workpiece

and lubricate it during the threading operation.

Specifications

Threading Capacity .......Pipe

1

/

2

″ through 1″

Cut-Off Capacity............Pipe

1

/

2

″ through 1″

Operating Speed ...........25 RPM (No Load)

Motor:

Type ............................Universal

Volts ............................115V Single Phase AC

50-60 HZ

Amps ...........................6.4

Controls.........................ON/OFF Toggle Switch and

ON/OFF Foot Switch

Chuck ............................Hammer-Style with

Replaceable Inserts; Cam

Action Rear Chuck

Coolant System.............16 Oz. Integral Coolant

Reservoir with Gerotor Pump

Weight ...........................59 lbs.

Standard Equipment

(Figure 1)

• Model 610 Quick-Opening Die Head,

1

/

2

″ – 1″ NPT

•

1

/

2

″ –

3

/

4

″ Oil-less Gold NPT Dies

• 1″ Oil-less Gold NPT Dies

• Model 334 Blade-Type Reamer

• Model 354 Roll-Type, Self-Centering Cutter

• 1 Quart RIDGID Thread Cutting Coolant

Rear Centering

Device

Chuck

Handwheel

Carrying

Handle

Carrying

Handle

Cutter

Die Head

Reamer

Foot

Switch

Carriage

Handwheel

ON/OFF

Switch

Foot Switch Clip

Reservoir

Vent Cap

Coolant Level

Sight Glass