1210 Oil-less Threading Machine

Ridge Tool Company8

5. When the coolant drops are visible from the die head,

release the die head. Coolant system is now primed.

6. Release the foot switch and remove your foot.

Operating Instructions

WARNING

Do not wear gloves or loose clothing when operating

Threading Machine. Keep sleeves and jackets but-

toned. Do not reach across the machine or pipe.

Do not use this Threading Machine if the foot switch

is broken or missing. Always wear eye protection to

protect eyes from dirt and other foreign objects.

Keep hands away from rotating pipe and fittings. Stop

the machine before wiping pipe threads or screwing on

fittings. Allow the machine to come to a complete

stop before touching the pipe or machine chucks.

Do not use this machine to make or break fittings. This

practice is not an intended use of this Threading

Machine.

Use in ventilated area to prevent accumulation of

coolant vapors.

Installing Pipe In Threading Machine

1. Check to insure the cutter, reamer and die head are

swung to the rear of the carriage.

2. Mark the pipe at the desired length if it is being cut to

length.

3. Insert the pipe into the Threading Machine so that the

end to be worked or the cutting mark is located about

4 inches to the front of the speed chuck jaws.

4. Insert workpieces less than 2 feet long from the front

of the machine. Insert longer pipes through either

end so that the longer section extends out beyond the

rear of the Threading Machine.

To avoid equipment tip-overs, position

the pipe supports under the workpiece.

5. Tighten the rear centering device around the pipe by

using a counterclockwise rotation of the handwheel

when viewed from rear of the Threading Machine.

This prevents movement of the pipe that can result in

poor thread quality.

6. Secure the pipe by using repeated and forceful coun-

terclockwise spins of the speed chuck handwheel

when viewed from the front of the Threading Machine.

This action “hammers” the jaws tightly around the pipe.

Cutting Pipe with No. 354 Cutter

1. Check to insure the reamer and die head are in the

UP position (Figure 8).

2. Move pipe cutter down onto pipe and move carriage

with lever to line up cutter wheel with mark on pipe

(Figure 8).

3. Tighten cutter feedscrew handle while keeping the cut-

ter wheel aligned with the mark.

4. Assume the correct operating posture.

This will allow you to maintain proper

balance and to safely keep control of the machine and

tools.

• Be sure you can quickly remove your foot from the

foot switch.

• Stand facing the ON/OFF switch.

• Be sure you have convenient access to tools and

chucks.

• Do not reach across the machine or workpiece.

5. Flip the switch to ON (Forward).

6. Grasp the pipe cutter’s feed handle with both hands

(Figure 8).

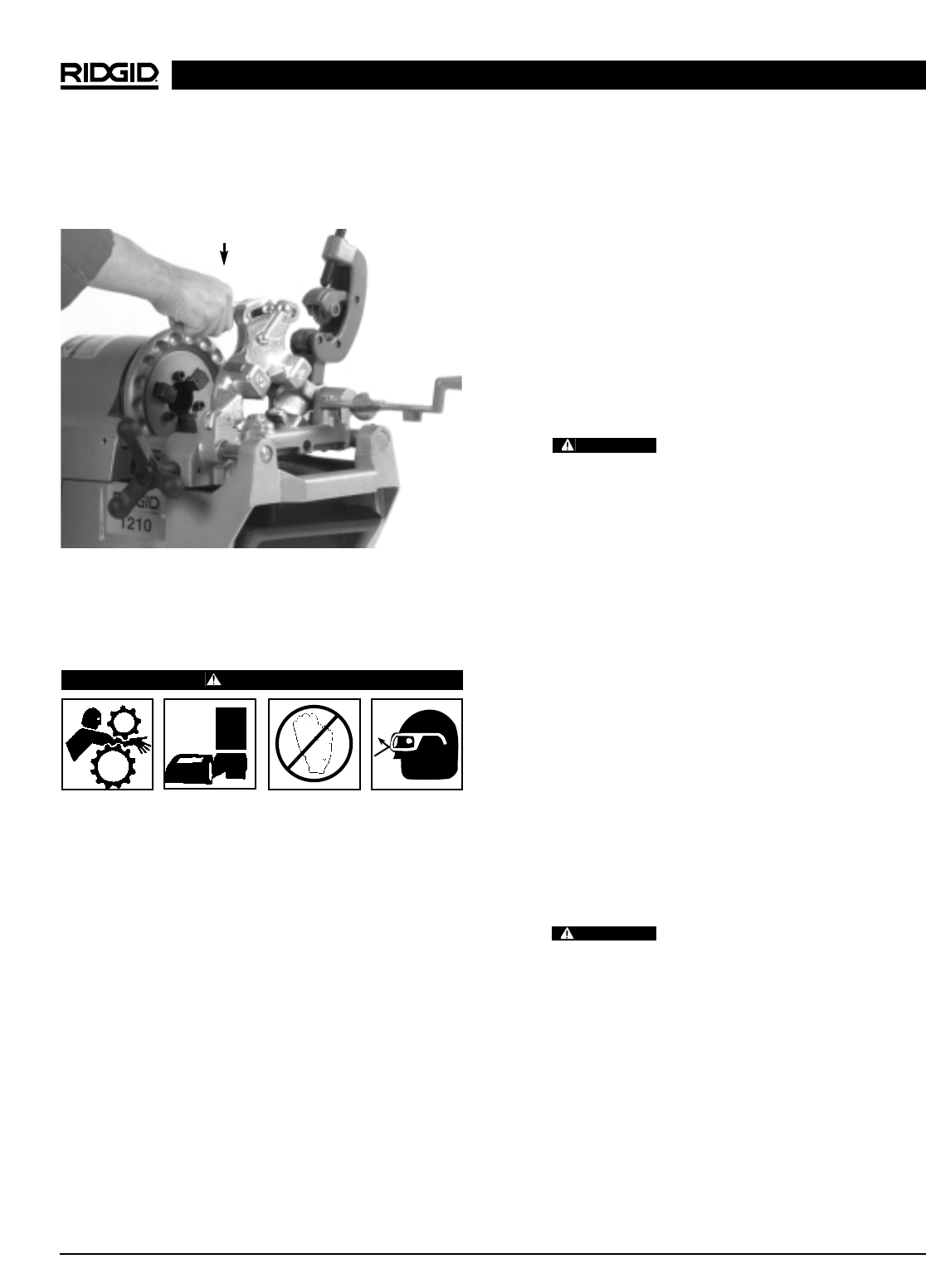

Figure 7 – Priming Coolant System

WARNING

WARNING