37

!@8;>

,47@=0%:!@8;

1. Pump not properly primed.

2. Wrong direction of rotation.

3. Speed too low.

4. Total head too high.

#0/@.0/,;,.4?D9/ =0,/

1. Air pockets or leaks in suction line.

2. Clogged impeller.

3. Foot valve strainer too small or clogged.

4. Excessive suction lift (over 15 ft.).

5. Insufficient positive suction head (for hot water).

6. Total head more than that for which pump is

intended.

7. Excessively worn impeller and wearing rings.

#,;4/(0,= 1:@;7492

1. Misalignment or a bent shaft.

2. Sagging motor mounts (over-oiling).

!@8;:>0>!=480

1. Air leaks in suction line.

2. Excessive amount of air in water.

3. Water seal in stuffing box not functioning.

4. Excessive suction lift and pump operating too

near shut-off point.

A0=7:,/0/=4A492&94?

1. Head much lower than that for which pump is

designed.

2. Speed too high or higher than that contemplated.

0.3,94.,7%=:@-70>,9/:4>0

1. Misalignment.

2. Excessive suction lift or vapor binding (hot

water).

3. Bent shaft and/or damaged bearings.

4. Suction and discharge piping not properly sup-

ported and anchored.

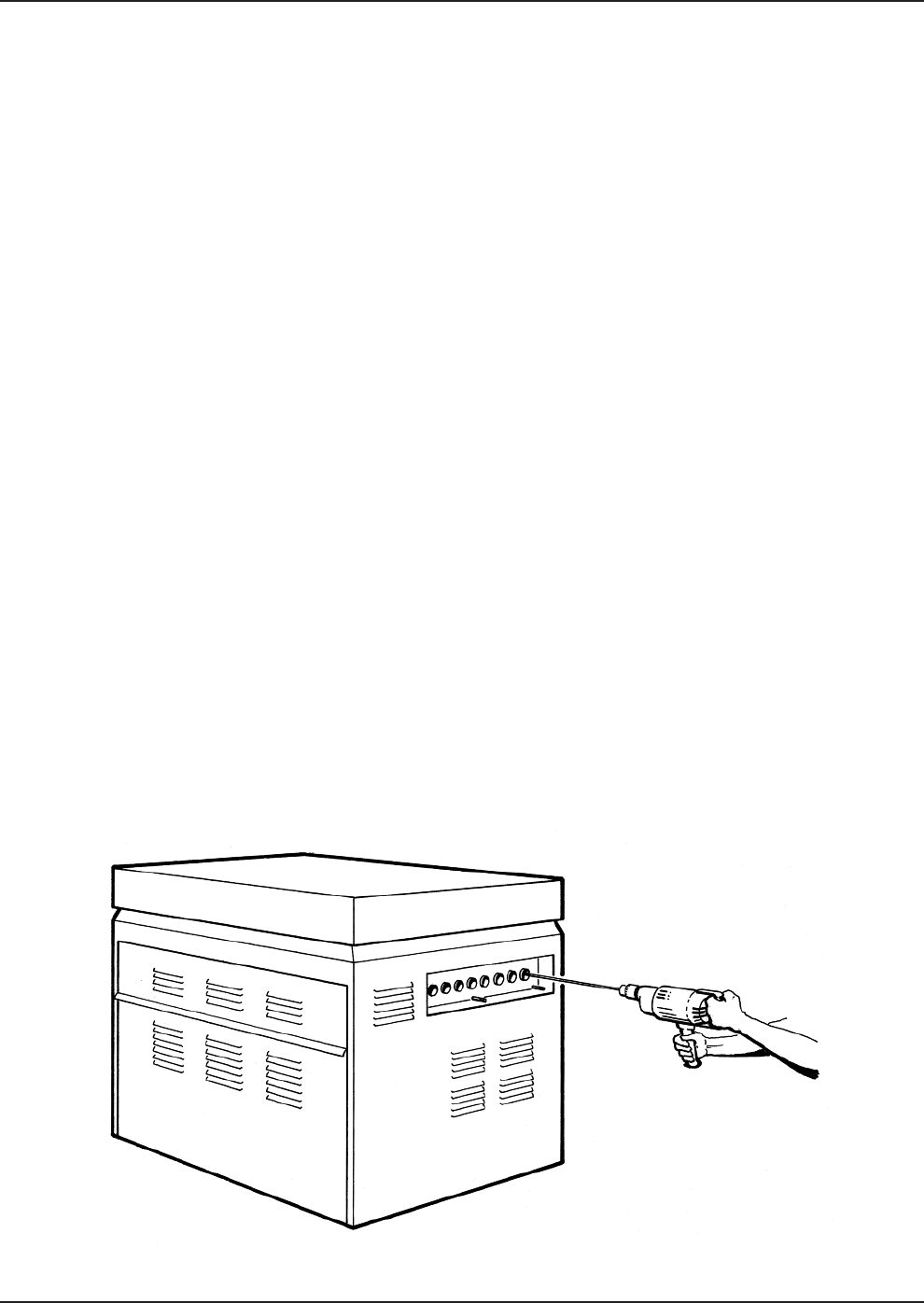

Fig. 50: Tube Cleaning Procedure