25

$%#%&!

01:=0$?,=?&;

Safe lighting and other performance criteria were met

with the gas manifold and control assembly provided

on the boiler when the boiler underwent tests specified

in the latest edition of ANSI Z21.13 Standard.

090=,7

Before lighting up a new installation, water should be

flowing through the boiler. Regulator should be set to

minimum 12 PSI.

477492$D>?080,?492

:470=>

Fill system with water. Purge all air from the system

using purge valve sequence. After system is purged of

air, lower system pressure. Open valves for normal

system operation. Fill system through feed pressure.

Manually open air vent on the compression tank until

water appears, then close vent.

&% Propane gas is heavier than air and

sinks to the ground. Exercise extreme care in light-

ing boiler in confined areas.

&% Pump must be off to check oil in bearing

assembly. Do not run pump without water in system.

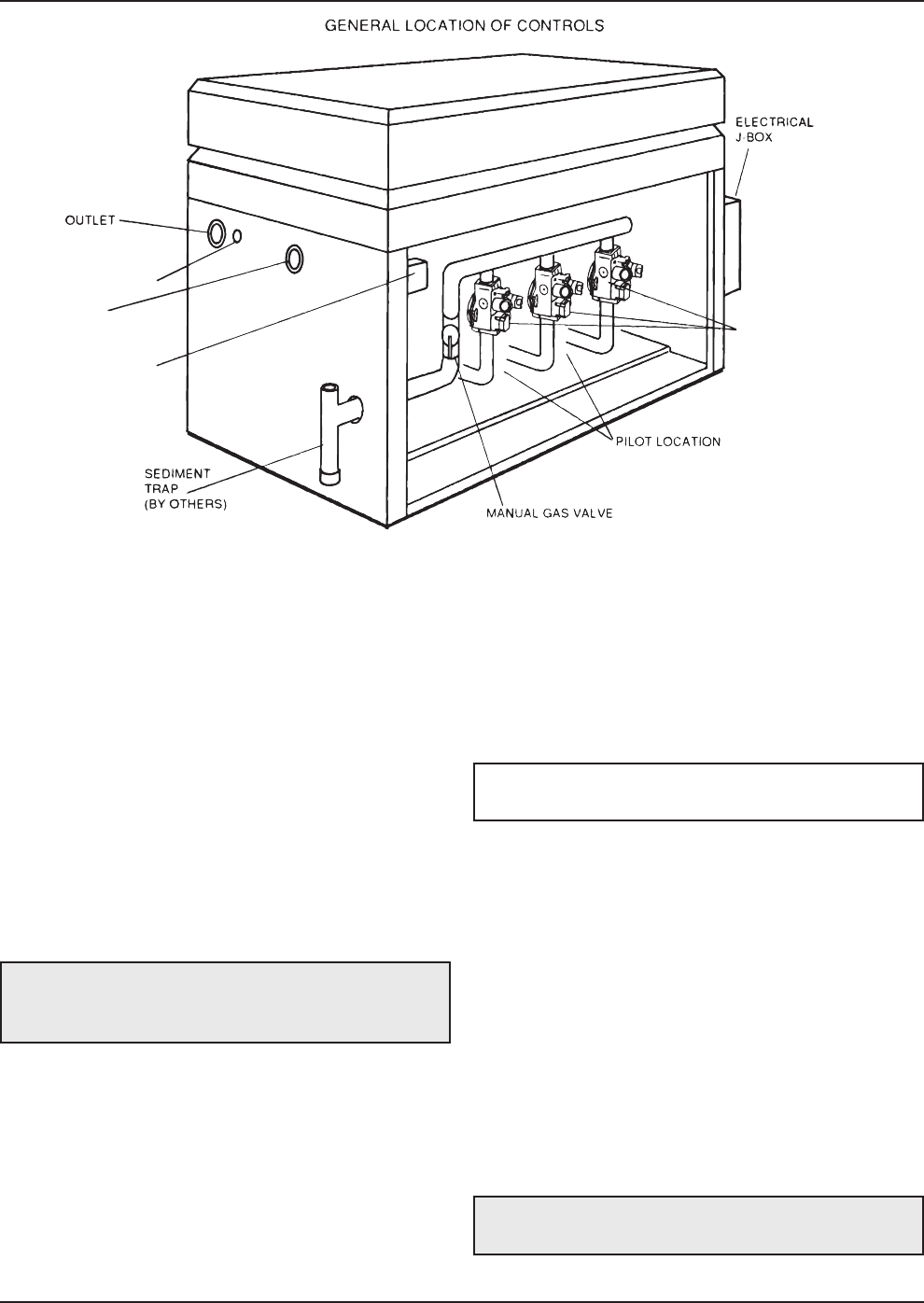

MECHANICAL

MODULATING

GAS VALVES WITH

R

EGULATOR

T

& P GAUGE

(NOT SHOWN)

INLET

HI-LIMIT

Fig. 37: General Location of Controls

?3D70907D.:7$D>?08>

0,?492:470=>

Fill through filler opening on the top on the Air-X Tank

to solution desired. Always maintain solution level in

sight glass.

94?4,7$?,=?&;!@8;,9/

:?:=

Many pumps are now direct-drive. They have no cou-

pler or bearing assembly. These pumps do not require

lubrication. Others require SAE-30 non-detergent oil to

lubricate both the motor and the bearing assembly.

Check pump motor for type before attempting to oil.

Clean dust and lint from pump and motor. Check pump

coupler and tighten if necessary. Flush system before

putting into operation to ensure that foreign material

does not damage pump seals.

% Raypak recommends the use of Ethylene

Glycol solution only.