18

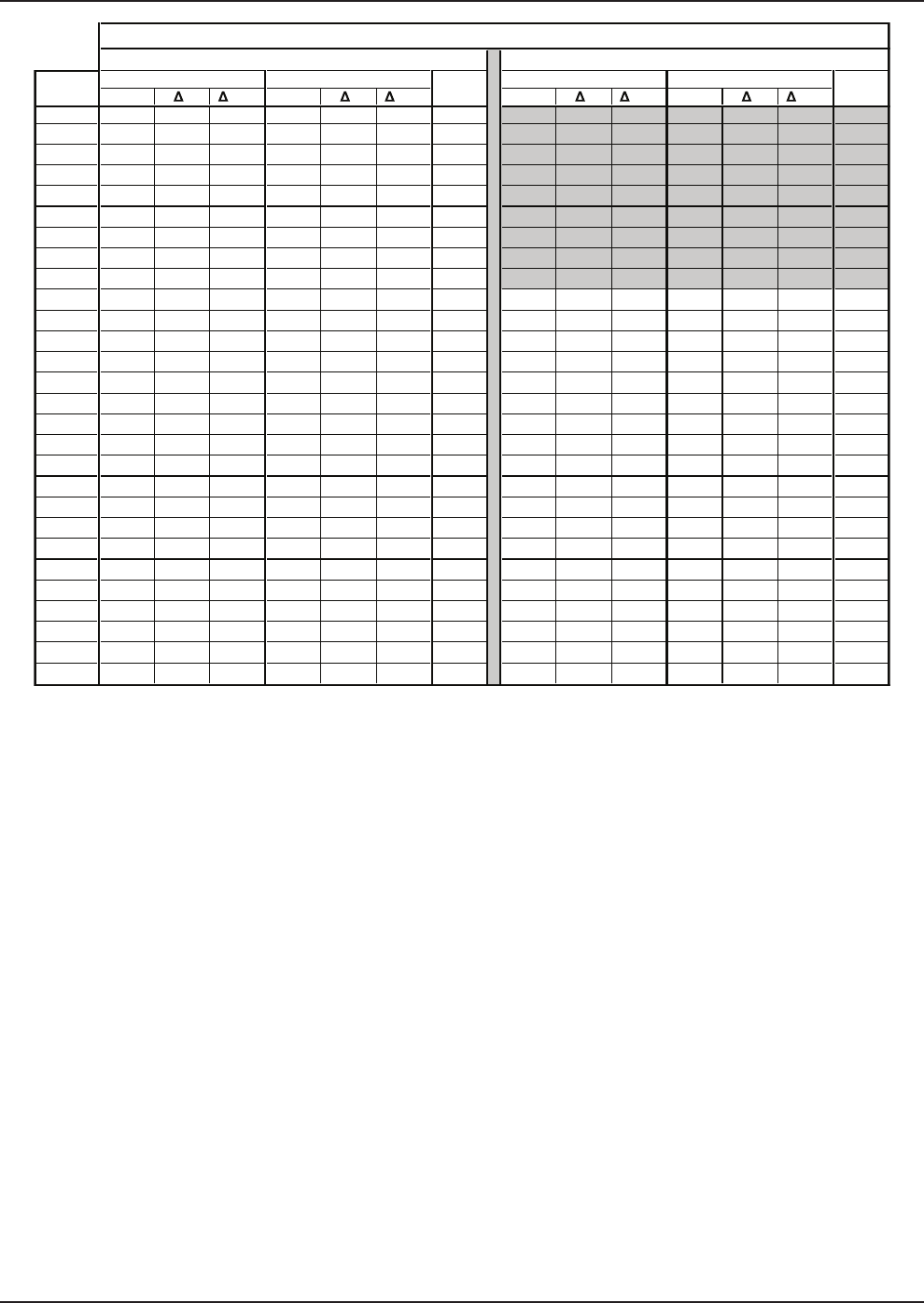

RDHRDHLEDOM

SIZE GPM

T P FT GPM T P FT CONN GPM T P FT GPM T P FT CONN

133* 22 10 14.7 10 22 3.3 1-1/4"

182/181

45 7 9.2 20 15 1.8

1-1/2"

2

60/261

45 10 9.4 20 22 1.9

1-1/2"

330/331

45 12 9.6 20 28 1.9

1-1/2"

400/401

45 15 9.8 20 33 2.0

1-1/2"

5

14

90 9 9 40 21 1.8

2"

624

90 12 9.5 40 26 1.9

2"

724

90 13 10 40 30 2.0

2"

8

24

90 15 10.5 40 34 2.1

2"

926

90 17 11 40 38 2.2

2

1/2"

200 8 9.7

9

0172.13"

962

90 18 11 40 40 2.2

2 1/2"

200 8 9.7

90 18 2.1 3"

1083

90 20 12 45 40 3.1

2 1/2"

200 9 10.3

90 20 2.3 3"

1125

90 21 12 47 40 3.3

2

1/2"

200 9 10.3

9

0202.33"

1178

90 22 12.5 49 40 3.8

2 1/2"

200 10 11

90 21 2.4 3"

1223

90 22 12.5 51 40 4.0

2 1/2"

200 10 11

90 22 2.4 3"

1287

90 24 13.2 53 40 4.5

2 1/2"

200 11 11.7

90 23 2.5 3"

1336

90 24 13.2 55 40 4.9

2 1/2"

200 11 11.7

90 24 2.5 3"

1414

90 26 14 58 40 5.8

2 1/2"

200 12 12.2

90 26 2.7 3"

1468

90 27 14 61 40 6.4

2 1/2"

200 12 12.2

90 27 2.7 3"

1571

90 29 14.5 65 40 7.5

2 1/2"

200 13 13

90 29 2.8 3"

1631

90 30 14.5 68 40 8.3

2 1/2"

200 13 13

90 30 2.8 3"

1758

90 32 15.4 73 40 10.0

2 1/2"

200 14 14.7

90 32 3 3"

1826

90 34 15.4 76 40 10.8

2 1/2"

200 15 14.7

90 33 3 3"

2100

200 17 14.8 90 39 3.2

3"

400 9 18

180 19 4 4"

2500

200 21 15.8 103 40 4.4

3"

400 10 18.8

180 23 4.1 4"

3001

200 25 16.7 124 40 6.7

3"

400 12 19.5

180 27 4.3 4"

3500

200 29 17.5 145 40 9.5

3"

400 14 20.5

180 32 4.5 4"

4001

200 33 18.7 166 40 13.0

3"

400 16 21.5

180 36 4.7 4"

MAXIMUM AND MINIMUM FLOW RATES

2

-PASS HEAT EXCANGER

1

-PASS HEAT EXCHANGER

NIMXAMNIMXAM

GPM Flow rates limited by maximum acceptable velocity through heat exchanger tubes. May be increased by 10% for closed heating

systems.

* 4 Pass Heat Exchanger

BOLD TYPE indicates Low NOx models.

difference between the inlet and outlet water when the

boiler is firing at full rate). For some boilers, the Delta

T is more than 20°F (22°-33°F) at the recommended

flow rates.

00/B,?0=#02@7,?:=

We recommend that a feedwater regulator be installed

and set at 12 PSIG minimum pressure. Install a check

valve or back flow device upstream of the regulator,

with a manual shut-off valve. Leave the valve open.

!4;492H0,?492:470=>

We recommend that all high points be vented and that

purge valves and a bypass valve be installed. A boiler

installed above radiation level must be provided with a

low water cut-off device. The boiler, when used in con-

junction with a refrigeration system, must be installed

so that the chilled medium is piped in parallel with the

boiler with appropriate valves to prevent the chilled

medium from entering the boiler.

#0.:8809/0/!@=20,941:7/>1:=

%D;4.,7D/=:94.$D>?08::6@;>

The boiler piping system of a hot water heating boiler

connected to heating coils located in air handling units

where they may be exposed to refrigerated air circulat-

ing, must be equipped with flow control valves or other

automatic means to prevent gravity circulation of the

boiler water during the cooling cycle.

%08;0=,?@=0!=0>>@=0,@20

The temperature & pressure gauge is standard equip-

ment on all hydronic heating and hot water supply

boilers. All temperature & pressure gauges are factory

mounted in the in/out header except for residential

boilers, Models 133 and 181-401. On these models

the temperature & pressure gauge is shipped loose for

field installation, and located in the outlet water con-

nection. All fittings required to mount gauge to piping

system are supplied by others.

Table H: Maximum and Minimum Flow Rates