22

Fig. 29: Mechanical Modulating Valve

M

ODULATING VALVES

W/ BUILT-IN REGULATOR

Fig. 28: Mechanical Modulating Valve Location

:/0:?:=4E0/:/@7,?4:9

The design uses a motorized valve which varies posi-

tion based upon an external controller that

communicates with the gas valve actuator, through a

3-wire 0-135 ohm wiper circuit. Minimum fire is 20%

of rate. The actuator runs on 120V power, and takes

26 seconds to go from fully closed to fully open.

Raypak offers a single-boiler digital controller which

drives the actuator; see controller options B-40 and

B-41 (includes outdoor reset). For systems with mul-

tiple boilers, see controller options B-45 through

B-47. For a field-supplied controller with a 4-20 mA

signal, see option B-35.

-

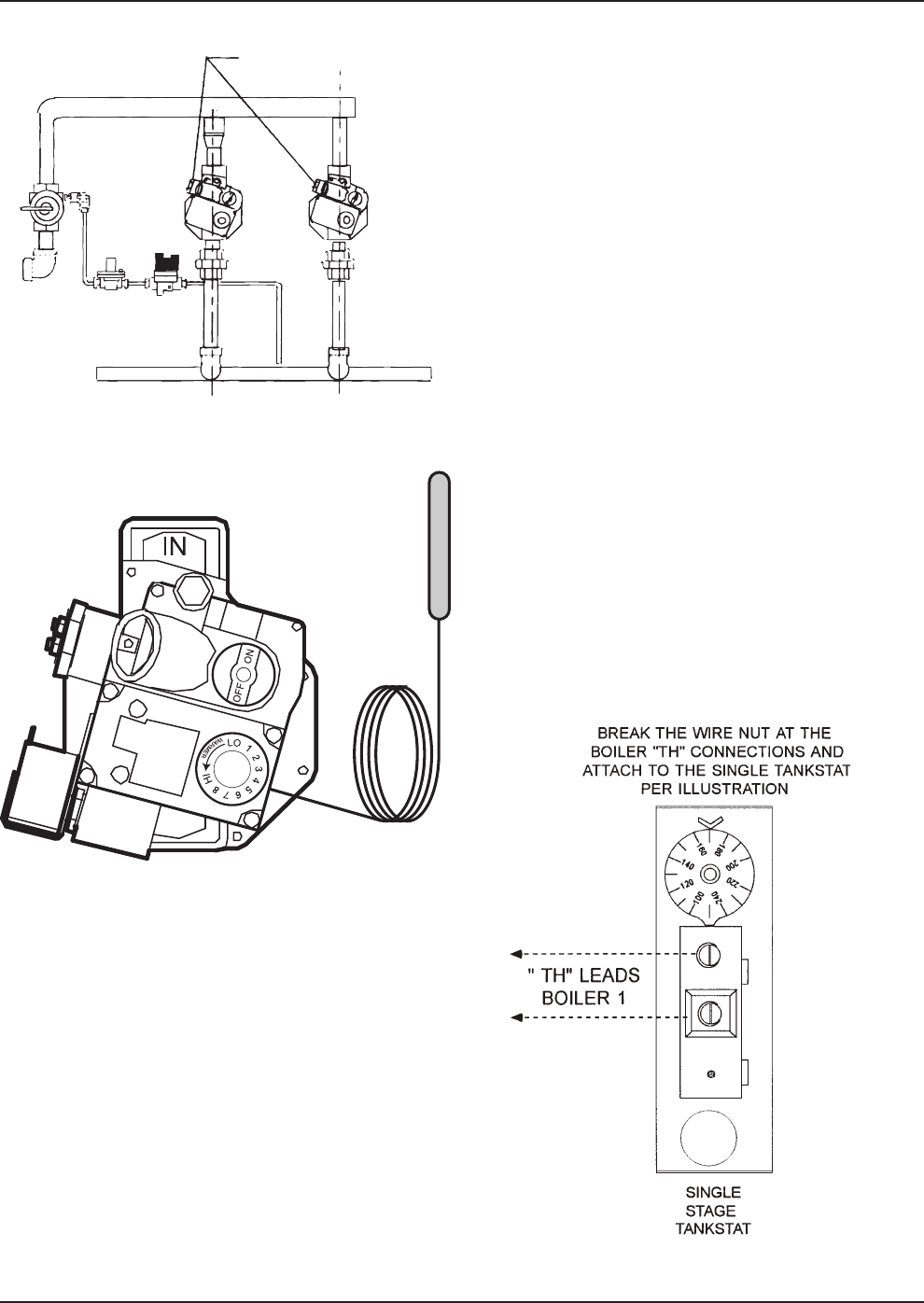

Fig. 30: Single Stage Tankstat

:/0$?,204=492

The boiler will fire at low fire when there is closure

across the stage 1 contacts. Thereafter, it will fire at

high fire when there is closure across the stage 2

contacts. Numerous staged controllers are available.

:/0 9 114=492

The boiler will fire at full fire when there is closure

across the TH contacts. Numerous mechanical

staged controllers are available (see Fig. 37), as well

as digital controllers offering additional features. A

typical wiring diagram for a mid-size H4 unit is shown

on page 35; this basic layout applies to most other

firing modes as well.

:/0$?,204=492

The boiler will fire at lowest setting when there is clo-

sure across the stage 1 contacts. Thereafter, it will

fire at increasing rates when there is closure across

the contacts for additional stages. Loss of closure

across stage 1 will shut down the entire boiler imme-

diately. Numerous digital controllers are available.

(:/0>

Connections for Tankstats in WH modes are shown in

Figs. 30 and 31.